Operation

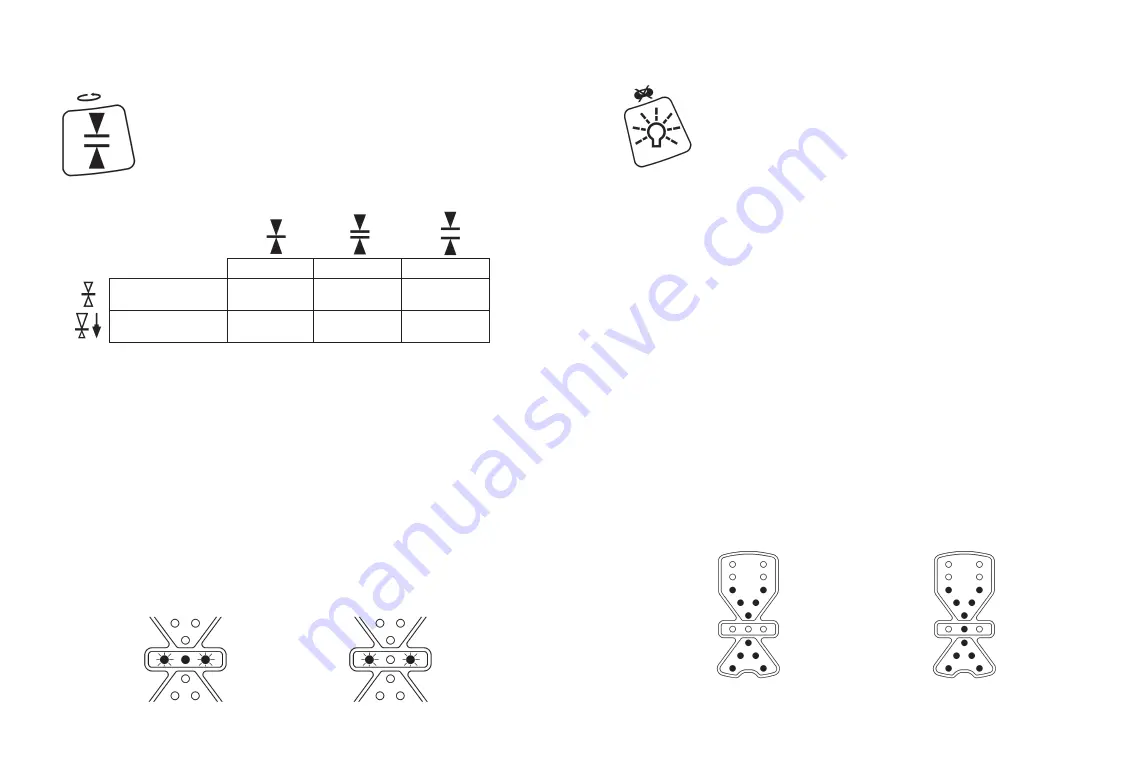

Deadband (Accuracy) Switch:

Each on-grade location has

three deadband or accuracy selections - fine, standard, and

wide. The center or grading deadbands are smaller than the

offset or excavating deadbands.

Pressing the switch once flashes the status LED of the current

selection. Pressing the switch again while the status LED is activated

changes the selection, sequencing from fine to standard to wide to fine, etc.

Fine

Standard

Wide

Center On-Grade

(Grading)

5 mm

(3/16 in)

10 mm

(3/8 in)

20 mm

(3/4 in)

Offset On-Grade

(Excavating)

12 mm

(1/2 in)

25 mm

(1.0 in)

50 mm

(2.0 in)

Laser Beam Averaging:

The secondary function for the Deadband Switch is

laser beam averaging. The laser beam averaging function senses the laser

strikes and applies the highest level of averaging appropriate for the laser

rotation speed. This may stabilize the LED grade display if the laser set-up

is unstable due to windy conditions or long range applications. The factory

default setting is Laser Beam Averaging ON.

The receiver can be set for no averaging. In this mode the receiver processes

and displays every single laser strike. To change between the two modes,

press and hold the power switch and then press and release the deadband

switch. The outer green on-grade LED's will flash to indicate averaging

selection. When the center LED is on, averaging is on. When the center LED

is off, averaging is off. Pressing this switch combination while the LED's are

activated will change the current selection between on and off.

Averaging ON

Averaging OFF

11

10

Operation

Display Brightness Selection:

The brightness switch controls

the LED grade display and blade tilt display brightness. Bright and

Dim are the selection options. Use Bright for daytime operation

if necessary and Dim for lower light conditions. Operating with

Display Dim selected will extend battery life.

When the brightness switch is pressed and the receiver is out of the laser beam,

the LED's will display a circle with the current setting. Press the brightness

switch again while the LED's are activated to change the setting. The LED's

will then display the new setting.

When the receiver is in the laser beam, simply press the brightness switch and

the setting will change.

Out Of Level Warning:

The secondary function for the Brightness Switch is

laser Out of Level (OOL) Warning. The Out of Level Warning is used with certain

lasers that have the ability to indicate they are out of level by changing their

rotation speed. The factory default setting is Laser Out of Level Warning off.

To activate the laser OOL Warning, turn the receiver on. Press and hold the

power switch and then press and release the brightness switch. If the center

green LED is not lit, the OOL Warning is off. Pressing the power / brightness

switch combination again while the "X" pattern is activated will turn the

warning on. The center green LED will come on to confirm the OOL Warning

is on. Pressing the switch combination again while the "X" pattern is activated

will toggle between on and off.

When the warning is turned on and the laser drops to 140 RPM, a flashing

"X" will appear on the display to let the machine operator know the laser is

out of level.

Laser Out of Level OFF

Laser Out of Level ON