Operation

Power:

Press the power switch on the touch panel to turn the

unit on. All the LED's will light briefly, then each LED grade

display row will turn on then turn off from top to bottom. Then

each status indicator will turn on and off. The current deadband

status and on grade location will momentarily display. If the

receiver is out of a laser beam, the center green LED will flash to confirm power

is on. If the receiver is in a laser beam, a corresponding LED grade display

will be indicated.

While the unit is on, pressing and holding the power switch and then pressing

the touch panel switches will activate secondary functions which are indicated

by the symbols above the switch.

To turn the power off, press and hold the power key until the LED's are lit, then

release. Settings will be retained the next time the unit is turned on.

Switch Functions

Tilt Indicator

: Press the tilt indication switch to turn the display on

or off. The LED status indicators will display a rolling sequence.

When the function is turned on, the LED's will sequence from

the center outward. When turned off, the LED's will sequence

from the outer LED's inward.

When on, the LED's will provide 5 channels of tilt

indication. The center LED will be on when the blade

or dipperstick is within the tilt accuracy setting. The

right side will light when the operator's right side of the

blade or dipperstick is low. The left side will light when

the left side is low.

Initially the blade tilt indication is set to level. It can be

set to match the current blade slope. See installation

notes on Page 15.

Tilt Indicator Accuracy

: Accuracy can be set to fine, standard or wide. Press

and hold the power switch and then press the tilt indicator switch to select and

cycle the tilt accuracy function. The current selection will flash rapidly. Pressing

this switch combination while the status LED is flashing will change the current

selection, sequencing from fine to standard to wide to fine, etc.

Fine

± 0.5º

Standard

± 1.5º

Wide

± 2.5º

8

13

Installation - General

Set up the laser in a convenient, safe location. Please refer to your laser

operator's manual. Ensure the laser is on a stable tripod. On windy, gusty days

it may be advisable to tie down or weigh down the tripod to make the laser

beam more stable.

Operating distances are dependent upon the rotating laser power.

The receiver

can pick up the beam from all directions (360°), but still requires a clear line of

sight between the laser and receiver.

If your laser has selectable rotation speeds, select a high rotation speed. The

receiver can process speeds up to 1200 RPM.

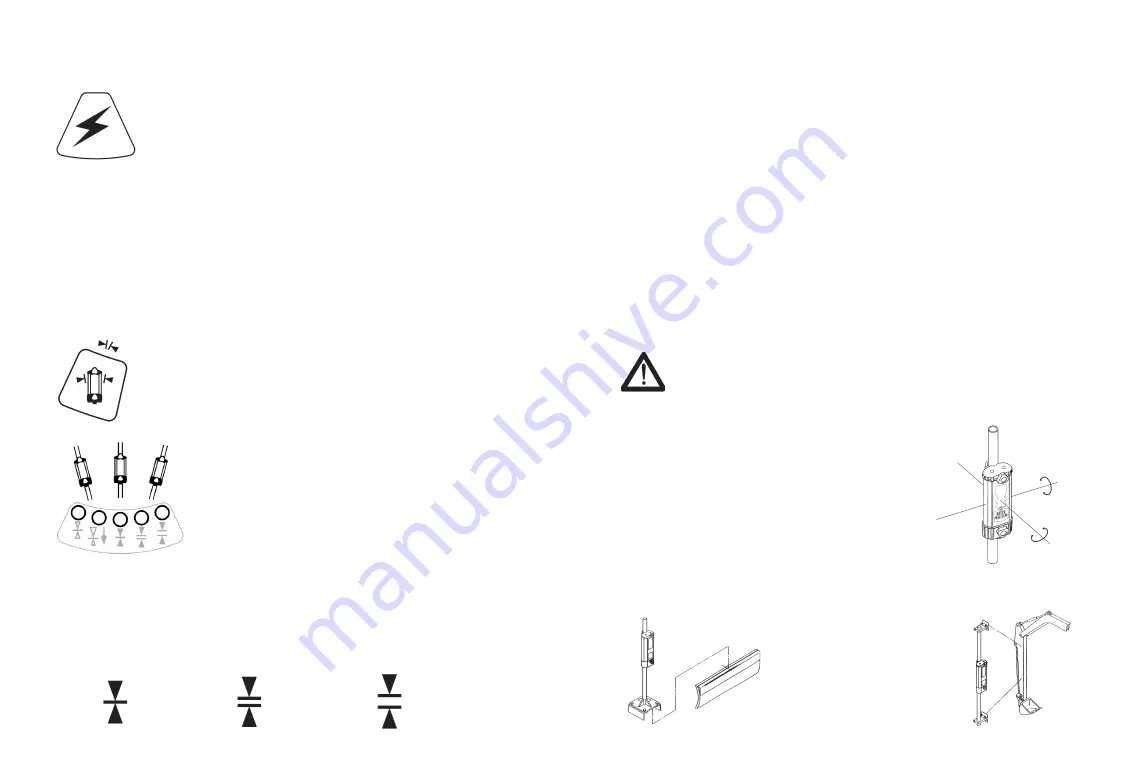

To mount the receiver on a mast, turn both the top and bottom knobs

counterclockwise until the mounting clamps in back open enough to fit around

the mounting mast. Place the receiver on the mast. The receiver will mount to

round tubing that has a 42 to 50 mm (1.66" to 2.00") outside diameter or to 38 mm

(1-1/2") square tubing. Turn the knobs clockwise to tighten. Loosen the two

clamps to remove the receiver from the mast.

WARNING:

Follow all safety precautions per the machines operator's

manual and follow all excavation and trench safety requirements

and practices.

Typical dozer

installation

Typical excavator

installation

The blade tilt and plumb indications are measured

inside the receiver. The blade tilt indicates side-to-

side position. Plumb indicates front-to-back position.

Masts and receivers must be properly aligned to the

machinery for accurate indications.

Assure dozer masts are aligned vertical both front-

to-back and side-to-side with the blade when the

blade is in its normal operating position.

For excavation, typically the mast points towards

the bucket teeth. Additional installation details can

be found on page 15.

Plumb axis

rotation

Blade tilt

axis rotation