Controls and Displays

LED Status Indicators

Touchpanel Switches

Deadband

(Accuracy)

Selection

Display

Brightness

Selection

On-Grade

Location,

Plumb On / Off

Blade Tilt

Indication

Blade Tilt

Accuracy

Plumb

Indication

Accuracy

Laser Beam

Averaging

Laser

Out-of-Level

Secondary Functions

Primary Functions

On-Grade

Location Indicators

Low Battery

Indicator Combination

Deadband (Accuracy)

Indicators

Center

On-Grade,

Grading

Offset

On-Grade,

Excavating,

Plumb On

Fine

Deadband

Standard

Deadband

Wide

Deadband

5 Light Blade Tilt Indication

16

5

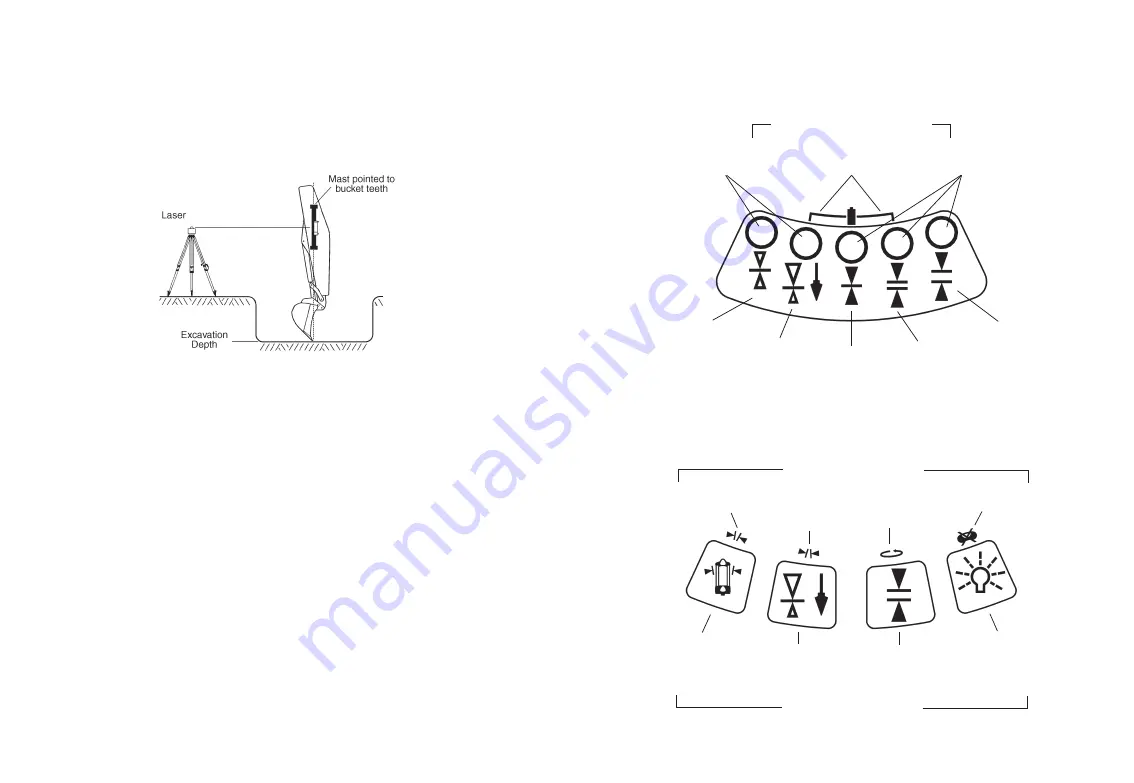

Installation - Excavating

When using on an excavator or backhoe, the dipperstick should be vertical or

near vertical and the bucket positioned so it can easily be repeated each time

a grade reading is taken. The bucket can be fully extended or curled as long

as it is consistent when grade readings are taken. The receiver can be set-up

in the trench or out of the trench if the cut elevation can be determined.

In Trench Set-Up

Position the machine and dig to the desired finished elevation.

Position the bucket in the grade checking position at the finished elevation.

Set the laser up in an appropriate location for receiver visibility and efficient

machine operation and turn it on.

Mount the mast on the side of the dipper arm. Point the mast at the bucket

teeth as illustrated if checking grade with the bucket fully extended. (If checking

grade with the bucket curled or other position, point the mast to the point of the

bucket that makes contact with the ground.)

Turn the receiver on and select the offset on-grade and the smallest deadband.

Place the receiver on the mast, tighten, and adjust the dipper arm so the

receiver is within the plumb range - solid LED's. Adjust the plumb indication

accuracy if desired.

Loosen the receiver and slide it up or down to get an on-grade display, then tighten.

Select the desired deadband and begin to excavate.

Take grade readings with the bucket in the grade checking position and the

grade display LED's solid.

Take a sample reading with the bucket "on-grade" and check to ensure the

elevation is correct.