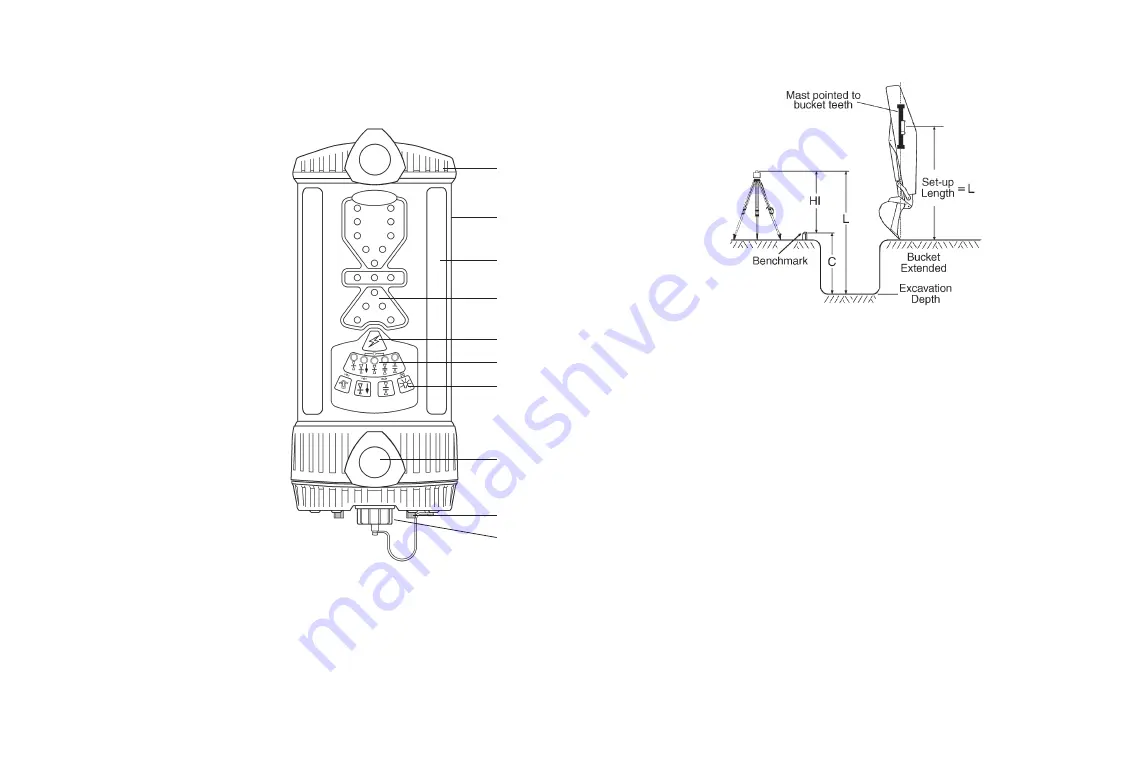

1. Aluminum cast upper and lower

housings.

2. Polycarbonate housing - protects

the electronics.

3. Receiving Window - four sets of

photocells spaced to allow 360 degree

reception.

4. Super-bright grade display LED's

are highly visible - graphically dis-

plays the blade or bucket position.

5. Power Switch turns the unit on

and off.

6. LED status indicators for on-grade

location, deadband selection, and

low battery warning. Also functions

as blade tilt indicator.

7. Touchpanel Switches - Primary

functions select blade tilt display, on-

grade location, on-grade deadband

(accuracy), and display brightness.

Secondary functions select blade tilt

accuracy, plumb indication accuracy,

laser beam averaging, and laser out-

of-level warning.

8. Mounting Knobs - large, front

facing knobs attached to stainless

steel clamps allow for quick and easy

installation to mast or magnetic mount.

9. Access screws - allows easy access to battery compartment for

replacement of batteries.

10. Accessory Connector and Dust Cap - connector accepts the cable

connector to the optional remote display, machine power cable, or

automatic control box. Connector also accepts Ni-MH battery charger.

Dust cap helps keep the connector clean.

1

2

3

7

8

4

5

6

9

10

Controls and Displays

4

17

Installation - Excavating

Out of Trench Set-Up

Set the laser up in an appropriate location for receiver visibility and efficient

machine operation and turn it on.

Place the bucket in the grade checking position and situate the machine so a

measurement can safely be obtained on the dipper arm. The dipper arm may be

set more horizontal to the ground for convenient measurements if necessary.

Determine the distance from the laser to the bottom of the trench (L). This is

the set-up length. The length is the height of the instrument (HI) plus the depth

of cut from the benchmark to the bottom of the trench (C).

Mount the mast on the side of the dipper arm. Point the mast at the bucket

teeth as illustrated if checking grade with the bucket fully extended. (If checking

grade with the bucket curled or other position, point the mast to the point of the

bucket that makes contact with the ground.)

Position the receiver so the set-up length (L) is the distance from the bucket

ground contact point to the offset on-grade symbol on the back label. (Set up

to center on-grade symbol if center on-grade will be used).

Turn the receiver on and select offset on-grade and the desired deadband.

Adjust the plumb indication accuracy if desired. (Select center on-grade if set

to center symbol).

Begin to excavate. Take grade readings with the bucket in the grade checking

position and the grade display LED's solid.

Take a sample reading with the bucket "on-grade" and check to ensure the

elevation is correct.