6

15

Installation - Slope Matching

The blade tilt indicator can be nulled or set to zero at a blade slope other than

level. This is used for matching an existing slope or setting the blade to a

predetermined slope.

The factory default setting of the blade tilt indicator is level. To set the blade

tilt indicator at a slope other than level, position the blade at the desired slope.

Ensure the receiver is aligned properly side to side and front to back with the

blade.

With the receiver on, press and hold the power switch and immediately press

and hold both the blade tilt switch and the display brightness switch. Continue

holding all three switches until a "0" symbol followed by a "Y" symbol is briefly

displayed. The blade slope is now nulled at the existing slope.

"Y" symbol

"O" symbol

To reset the blade tilt indication back to level, position the blade to level and

check with a four-foot level or other method. Repeat the above calibration

procedure with the blade level.

This procedure may also be used to correct the display when a mast is not

aligned properly to the blade.

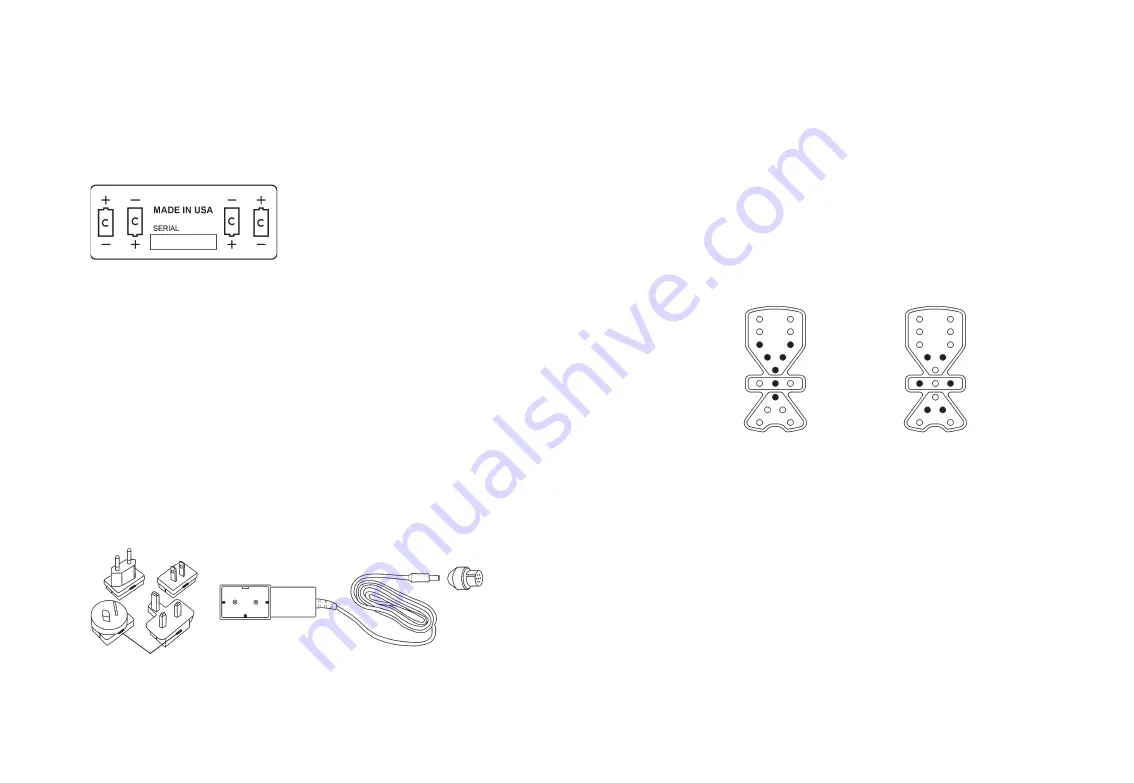

Battery Installation / Charging

Battery Installation:

Remove the BULLSEYE from its carrying case. Hold the

unit so the accessory connector is pointing upwards. Remove the dust cap

from the accessory connector. Loosen the two thumb screws and remove

the battery access cover. Install four “C” cell batteries as shown on the label

diagram inside the battery compartment noting the (+) and (-) terminals.

Replace the battery access cover. Firmly tighten the two thumbscrews. Ensure

the battery access cover is aligned and fully engaged into the battery housing.

Use a screwdriver if necessary. Replace the accessory connector dust cap.

Nickel Metal Hydride (Ni-MH) Batteries:

Batteries are initially shipped fully

charged but the charge may decrease over time prior to first use. They may

require 2 or 3 charging cycles to obtain maximum battery life. To charge, remove

the dust cap from the accessory connector. Insert the cannon adapter into the

receiver accessory connector aligning the slot and connector key. Insert the

charger female barrel connector into the cannon adapter.

Assure the proper AC prongs are on the charger. To change the prong

configuration, press the tab release and remove the existing prong adapter.

Align the key slots and press in the proper adapter.

Plug the charger into an appropriate outlet. Do not operate the receiver when

it is charging.

Battery installation diagram /

Serial number label

The batteries may also be charged with a 12-volt auto lighter adapter.

Cannon

Adapter

Charger

Prongs

Tab

Release