Installation

Position the RD15 in the machine's cab so the operator can

easily see the LED display during machine operation. Assure it

does not obstruct other operator functions. The RD15 includes an

assortment of mounting hardware including magnets, double-sided

tape, mating Velcro strips, and a rubber strap. Holes are provided

on the mounting plate for user provided hardware if necessary.

An optional swivel mount is available. Choose the appropriate

mounting hardware for your particular situation to secure the display

in a convenient viewing location.

NOTE:

The RD15 has a vented

drain hole in the bottom of the unit near the cable connector that

must face downward.

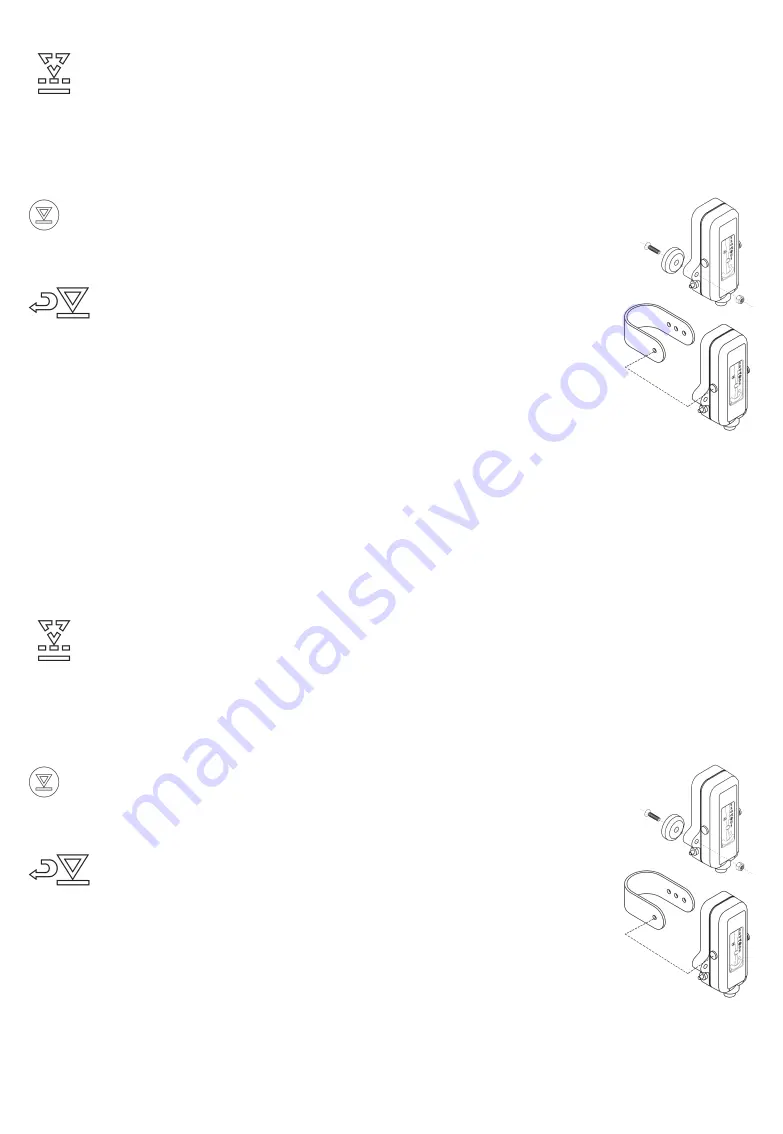

Magnet installation:

Install the provided

screw through the magnet and through

the mounting plate tab as shown. Secure

with the provided nut and tighten. Repeat

for the other side.

Mounting strap:

Install a hole of the

rubber strap around a mounting strap

tab. Wrap the strap around a suitable

support and secure the other end of

the strap around the other strap tab.

Ensure there is a snug fit.

Tape / Velcro:

Double sided sticky tape and mating Velcro strips

allow mounting on various surfaces of the machine. Peel off

the protective backing of the adhesive side(s) and apply to the

appropriate clean location on the back of the remote display and

then a clean machine surface.

3

10

Operation - Function Switches

Set Temporary Offset:

The Set Temporary Offset

function allows a current laser strike location to

become the second temporary on-grade location.

This is useful for temporarily raising or lowering the

offset on-grade location. To activate, position the

receiver to the desired temporary offset elevation while receiving

a laser strike. Press the right side Select Function switch 2 times.

The second LED from the top will light. Press the left side Set

Function switch one time to set (press for less than 2 seconds

to avoid turning off).

The grade indication will now show green on-grade and

the amber Offset Elevation LED will flash if the command

is accepted.

NOTE:

The Temporary Offset function will not operate when a

MCR3 is in the angle compensation (ACE) mode.

To return to the initial offset on-grade location,

press the right side Select Function switch three

times. The third LED from the top will light. Press

the left side Set Function switch one time to set

(press for less than 2 seconds to avoid turning off). The amber

Offset Elevation LED will turn solid confirming return to the offset

location.

Alternatively, to return to the default on-grade location, press the

right side Select Function switch four times and press the left

side Set Function switch one time to set.

Installation

Position the RD15 in the machine's cab so the operator can

easily see the LED display during machine operation. Assure it

does not obstruct other operator functions. The RD15 includes an

assortment of mounting hardware including magnets, double-sided

tape, mating Velcro strips, and a rubber strap. Holes are provided

on the mounting plate for user provided hardware if necessary.

An optional swivel mount is available. Choose the appropriate

mounting hardware for your particular situation to secure the display

in a convenient viewing location.

NOTE:

The RD15 has a vented

drain hole in the bottom of the unit near the cable connector that

must face downward.

Magnet installation:

Install the provided

screw through the magnet and through

the mounting plate tab as shown. Secure

with the provided nut and tighten. Repeat

for the other side.

Mounting strap:

Install a hole of the

rubber strap around a mounting strap

tab. Wrap the strap around a suitable

support and secure the other end of

the strap around the other strap tab.

Ensure there is a snug fit.

Tape / Velcro:

Double sided sticky tape and mating Velcro strips

allow mounting on various surfaces of the machine. Peel off

the protective backing of the adhesive side(s) and apply to the

appropriate clean location on the back of the remote display and

then a clean machine surface.

3

10

Operation - Function Switches

Set Temporary Offset:

The Set Temporary Offset

function allows a current laser strike location to

become the second temporary on-grade location.

This is useful for temporarily raising or lowering the

offset on-grade location. To activate, position the

receiver to the desired temporary offset elevation while receiving

a laser strike. Press the right side Select Function switch 2 times.

The second LED from the top will light. Press the left side Set

Function switch one time to set (press for less than 2 seconds

to avoid turning off).

The grade indication will now show green on-grade and

the amber Offset Elevation LED will flash if the command

is accepted.

NOTE:

The Temporary Offset function will not operate when a

MCR3 is in the angle compensation (ACE) mode.

To return to the initial offset on-grade location,

press the right side Select Function switch three

times. The third LED from the top will light. Press

the left side Set Function switch one time to set

(press for less than 2 seconds to avoid turning off). The amber

Offset Elevation LED will turn solid confirming return to the offset

location.

Alternatively, to return to the default on-grade location, press the

right side Select Function switch four times and press the left

side Set Function switch one time to set.