3

FuturaSun srl – The specifications in this manual are subject to revisions without further notice

This document applies to the module series FU XXX M ZEBRA

1. General Information

The photovoltaic (PV) modules FU XXX M

ZEBRA, (hereafter “FU XXX” or “FU”) are

devices that produce electrical energy by

converting the sunlight’s radiation reaching

their surface, when appropriately exposed,

into continuous/direct current (DC).

The FU modules are intended to be used in

photovoltaic module systems connected to the

electrical grid. It is also possible to use them in

battery powered photovoltaic module systems

(stand-alone).

The rated currents at Standard Test

Conditions (STC) of the FU modules are

variable depending on the model and the

relative power rating, as indicated in the

respective

technical data sheets.

Most of the

electrical parameters of the modules, specified

in the datasheets, are determinable only by

using special instrumentation in the laboratory;

therefore, only some of them are measurable

outside

of

a

lab,

using

common

instrumentation

(voltmeter,

AM

meter,

solarimeter/pyranometer).

It is possible, following very precise

procedures,

to

carry

out

electrical

measurements of voltage and current as

snapshots, which enable you to monitor the

operation of the modules and determine

possible, although rare, anomalies.

The electrical output parameters for FU

modules, of technical importance during the

operation, installation and maintenance, are

the following:

•

Voltage at open circuit (V

oc

) with

tolerance of ± 4%

•

Current at short circuit (I

sc

) with

tolerance of ± 5%

•

Voltage at point of maximum power

(Vmpp)

•

Current at point of maximum power

(Impp)

•

Power (P

max)

with tolerance of ± 3%

•

Solar radiation in W/m

2

at the time

•

Temperature of the modules

The general performance of the modules is

heavily dependent on the intensity of the

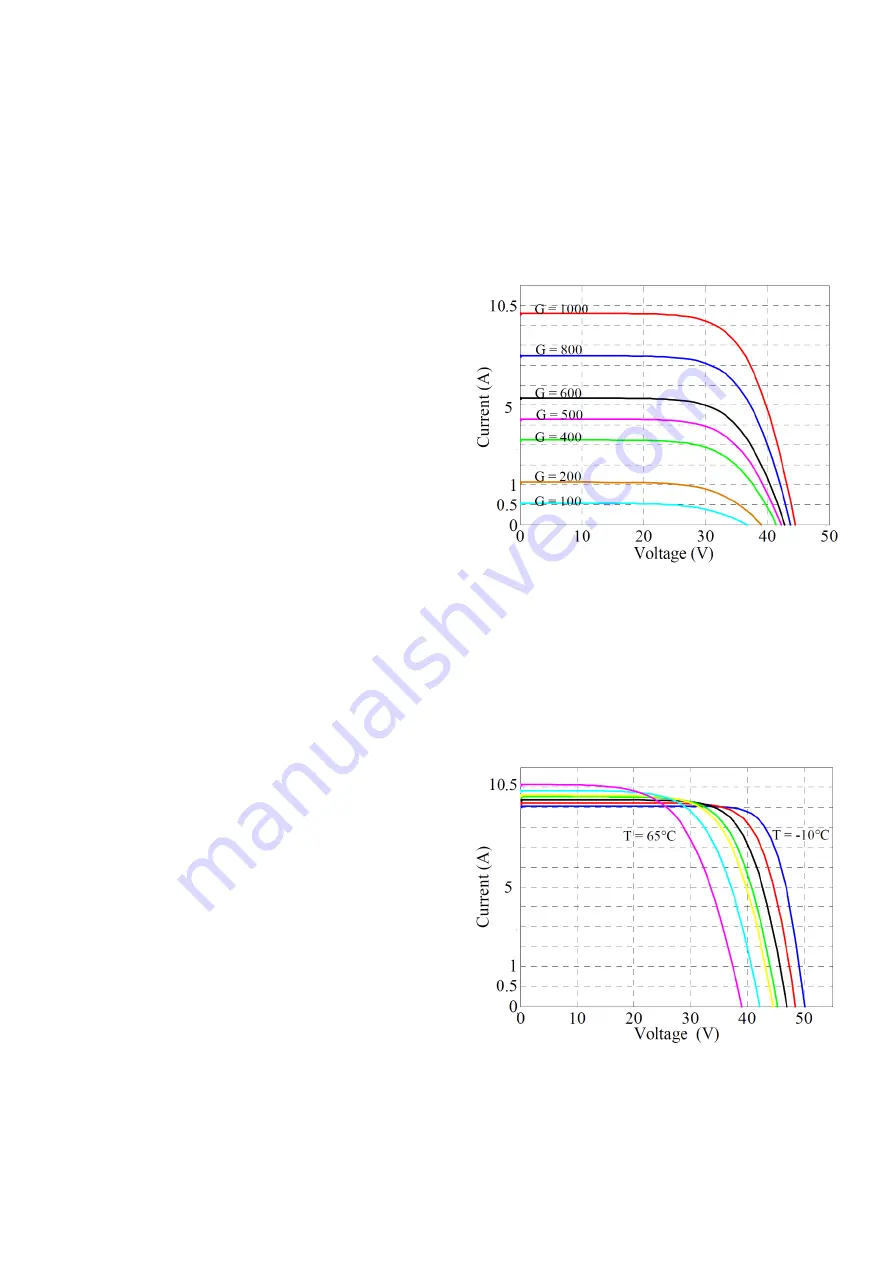

incident solar radiation, as illustrated in Fig.1.

Acheiving maximum performance requires

proper installation, with the modules oriented

towards the South in nothern hemisphere and

their surface exposed as perpendicularly as

possible to the incident rays of the sun;

furthermore, avoiding any shading caused by

obstacles in and around the area of

installation.

Fig. 1:

IV curve at different irradiance

A high ambient temperature and therefore, an

increased operational temperature of the

modules, also contribute to a proportional

reduction in electrical performance. Please

see fig. 2

Fig. 2:

IV curve at different temperatures

In order to optimize the production of electrical

energy of the modules, and therefore of the

system connected to an electrical grid, it is the