4

FuturaSun srl – The specifications in this manual are subject to revisions without further notice

This document applies to the module series FU XXX M ZEBRA

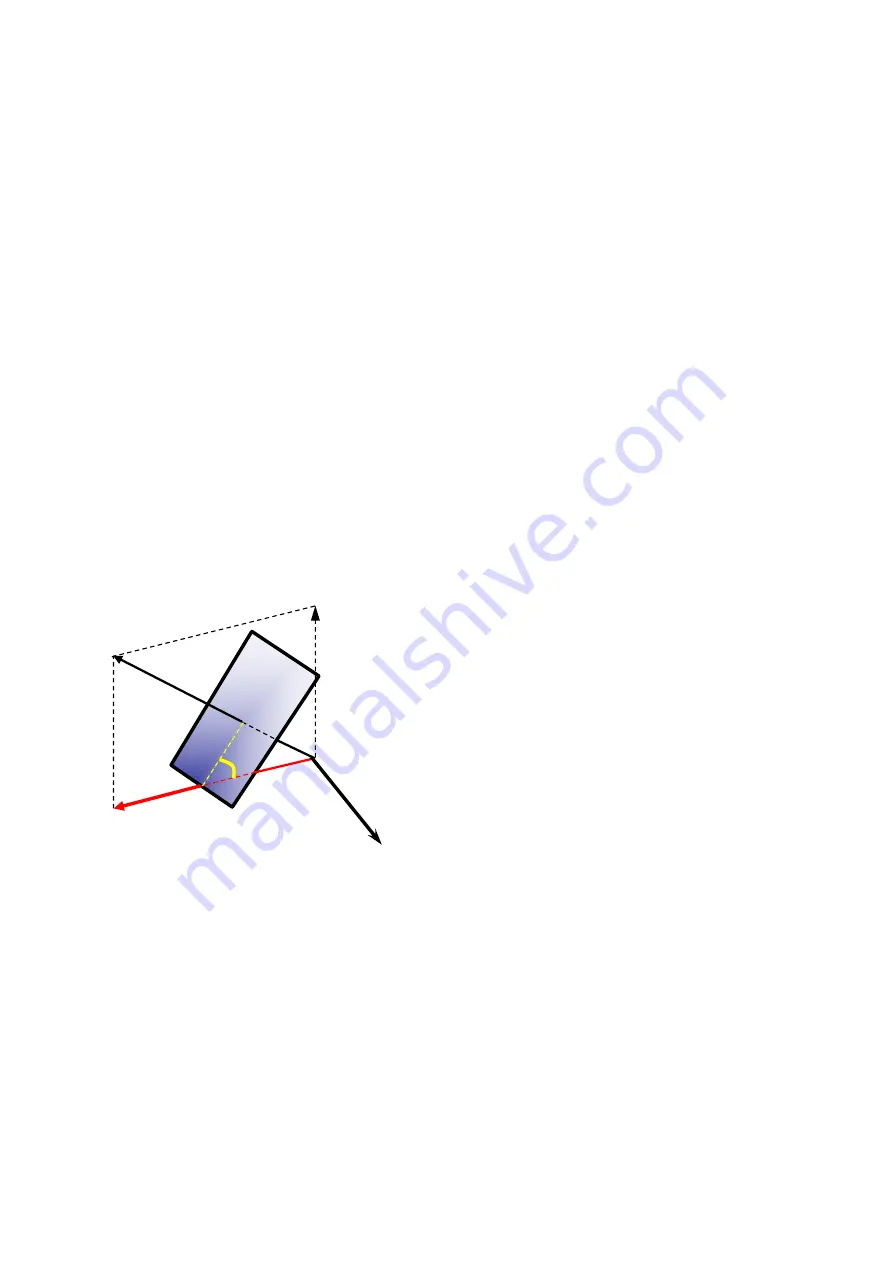

responsibility of the installer to make sure the

modules are positioned as much as possible

facing south in northern hemisphere, with the

tilt angle (β) (inclination of the surface of the

modules in respect to the ground, as shown in

Fig.3) optimal for the type of desired

application.

The tilt angle of ideal average throughout Italy

is

β = 30°

;

however, even the inclination typical

the roof of a dwelling (β = 15-20°), being

already an inclined plane, could make the

angle acceptable, if not ideal, for the

installation of coplanar modules on it (using a

special standard structure for support).

Depending on the variation of the tilt angle of

the modules with respect to the ground, or of

their orientation in relation to facing south

(Azimuth), there will be changes in the annual

average amount of energy produced by the

modules themselves, and therefore, of the

plant connected to the network to which they

are linked.

Fig. 3:

Orientation Vs. Azimuth

2. Disclaimer of Liability

Since the methods of system design,

installation techniques, handling and use of

this product are beyond company control;

FUTURASUN does not assume responsibility

and expressly disclaims liability, for loss,

damage or expense resulting from improper

installation, handling or use.

3. IEC 61215 & 61730 certifications

This product meets or exceeds the

requirements set forth by IEC 61215:2016 and

61730:2016 for PV Modules. These standards

cover flat-plate PV modules and panels

intended for installation on buildings or those

intended to be freestanding.

This product is

not intended for use where artificially

concentrated sunlight is applied to the module.

4. Limited Warranty

Please refer to FUTURASUN General Sales

Conditions and Product and Performance

Warranty for details of the modules’ limited

warranty. Failure to comply with this Safety

and Installation Manual will invalidate

FUTURASUN Warranty for the PV modules as

stated in the Product and Performance

Warranty.

5. Module Specification

Please refer to the technical datasheet for the

module FUTURASUN FU XXX respectively for

electrical performance data. These electrical

data are measured under Standard Test

Conditions (STC) of 1000 W/m

2

irradiance,

with Air Mass (AM) of 1.5 spectrum, and a cell

temperature of 25°C.

6. Safety Precautions

Installation should be performed only by

authorized personnel!

•

Module installation must be performed in

compliance with the latest IEC code (CEI

in Italy).

•

Within the modules, there are no user

serviceable parts. Do not attempt to repair

any part of the modules. Contact your

module supplier if maintenance is

necessary.

•

In order to reduce the risk of electric shock,

prior to installing the modules, remove

metallic jewelry and use insulated tools

during installation.

•

Do not expose the modules to artificially

concentrated sunlight!

•

Do not stand on, drop, scratch, or allow

objects to fall on the modules.

•

Do not lift the modules at the connectors or

junction box!

•

Do not install or handle the modules when

they are wet or during periods of high

winds.

•

Do not use oil-based lubricants on any part

of the junction box as this can cause long-

term damage to the plastics.

East

b

South