2

ARMS

COM AQUA TL UM REV. 02

20

AQUA TL

7

Arms

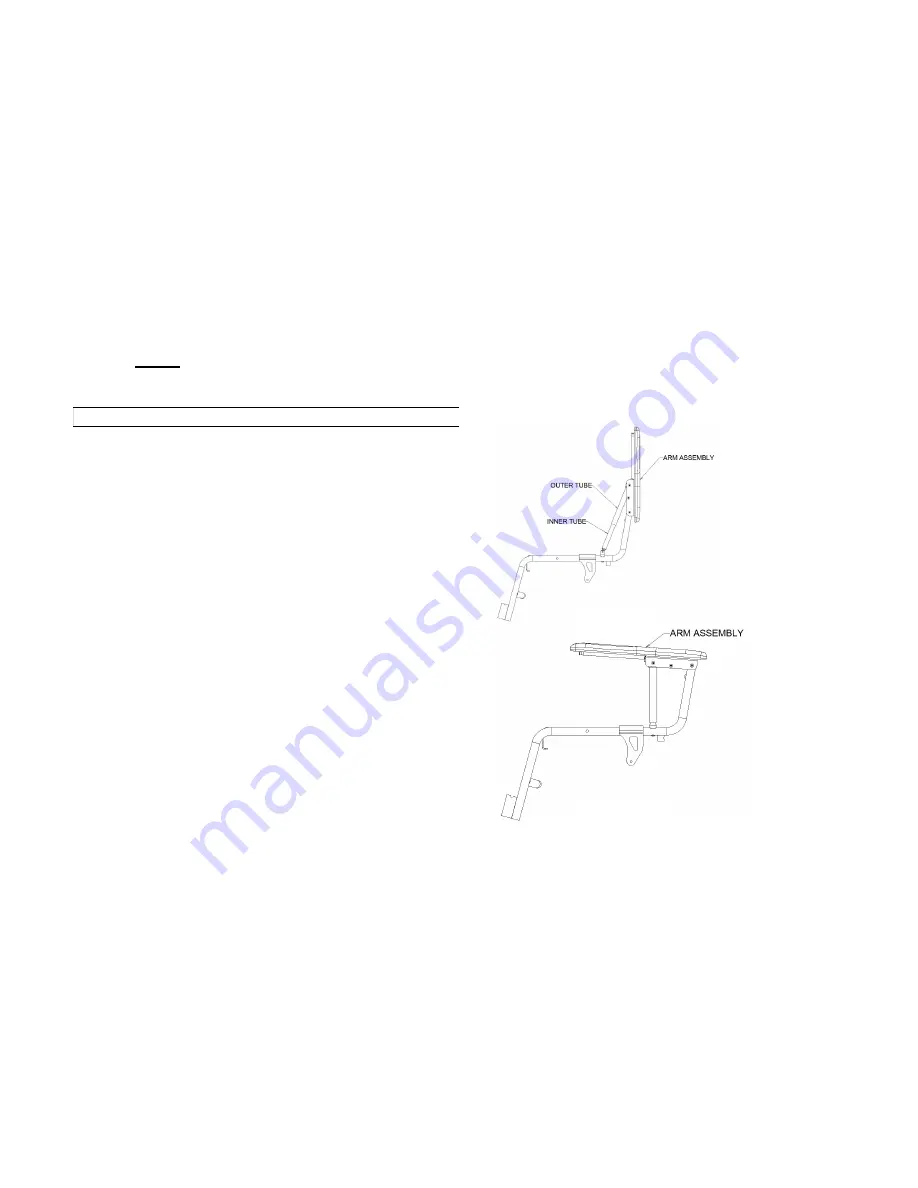

Adjusting The Arms Figure 3Figure 4

WARNING

After

ANY

adjustments, repair or service and

BEFORE

use,

make sure all attaching hardware is tightened securely –

otherwise injury or damage may occur

.

Rotating Arm Assembly Upwards\Downwards

1.

Grasp the top portion of the arm assembly and

rotate the arm upwards to the position shown in

the figure in lower right corner. One should

notice the arm outer tube sliding along the arm

inner tube in order to achieve a large rotation

angle and help to support the armrest while it is

resting vertically.

2.

At this point the arm assembly should come to a

stop. The occupant can be transferred to another

device such as a wheelchair or bed.

3.

In order to bring the arm assembly down to the

‘normal’ position grasp the top portion of the arm

assembly and rotate the arm downwards to the

position shown in the lower left corner until the

arm comes to a stop.

FIGURE 1

FIGURE 2

Summary of Contents for Aqua TL

Page 1: ...USER MANUAL Aqua TL ...

Page 35: ......