Section 50

00-02-1031

2019-08-07

- 22 -

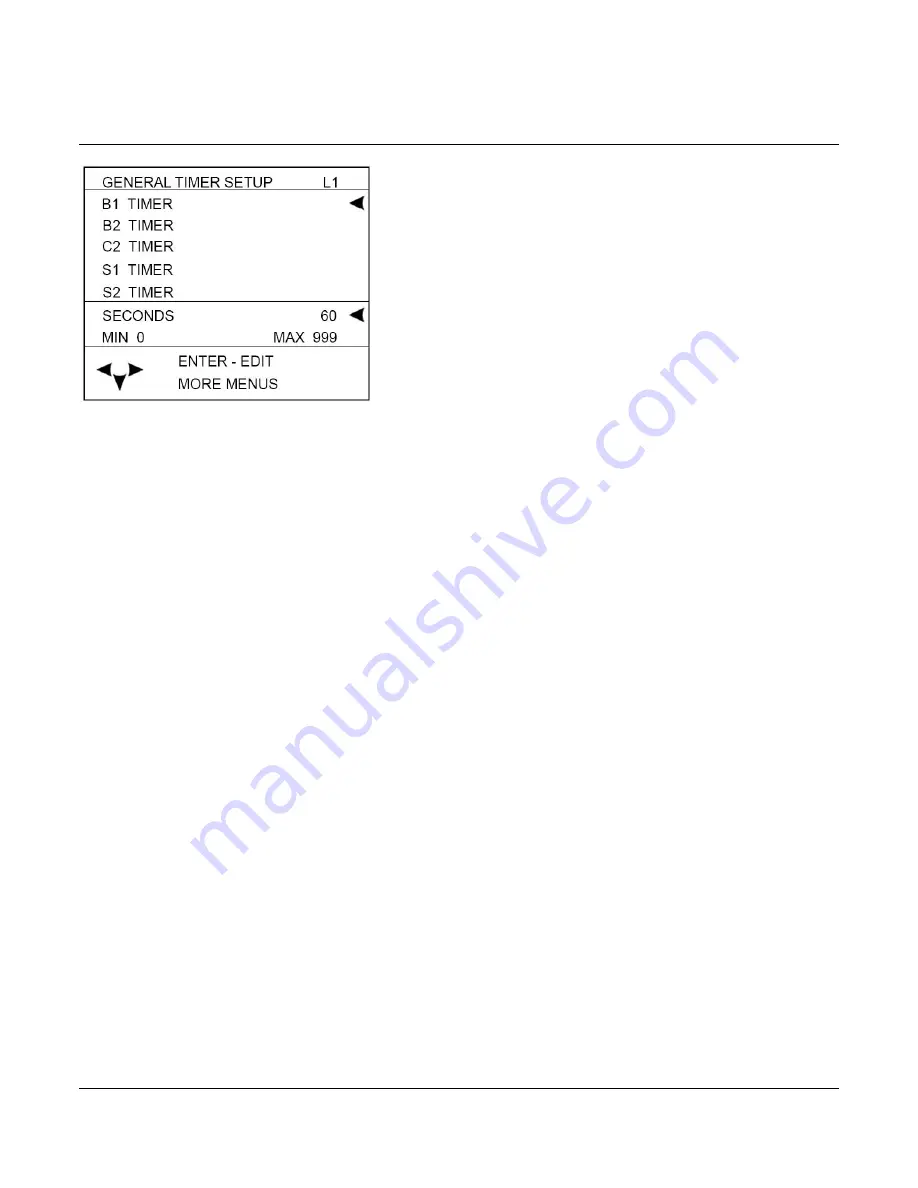

General Timer Setup Screen

User may edit all general purpose timers. Generally, global

timers affect driver operation. They also help define an

event arming condition.

B1:

All event types can be associated with, and locked out

by, a Bx timer. B1 is the first global timer used for delaying

an event condition detection. The timer starts and runs in

the running States of the controller operation. B1 is also

known as the Lockout Timer, start bypass or start/run timer.

B2:

The second global timer used for delaying event condition detection. B2 is also known as a secondary

Lockout Timer.

C2:

The delay after reaching the Run Loaded State that allows Class C2 events to arm. Class C events require

a clear reading sustained for 2 seconds to arm. This time used as stabilization time for any manual loading to be

operated and the load to stabilize on the machine.

S1-4:

Users have up to four (4) options to assign additional special global timers to signals. The Sx timers begin

concurrently with the Bx timers.

No Flow:

The global delay used for delaying the triggering of a no-flow event. This global no flow timer is

enabled after B1 expires and begins timing after any of the pulse transition times configured in the digital input

dialog expires.

Test:

Time given to allow for maintenance testing of end devices without triggering a fault or shutdown condition.

The timer initiates when switched to test mode.

Ignition On Delay:

Time delay before the assigned ignition output turns on. This is typically used to delay

ignition until engine has started cranking (also known as a purge delay).

Fuel On Delay:

Time delay before the assigned fuel valve output is turned on. This is typically used to delay fuel

until ignition has been turned on.

Ignition Off Delay:

Time delay before the assigned ignition output turns off. This is typically used to burn

remaining fuel vapors after the fuel valve is turned off.

Power Save Timer:

Time delay that begins timing upon shutdown or stopping of the equipment, and will turn off a

configurable Power Save digital output that can be used to remove power to the controller or other equipment to

save batteries.