Section 15

00-02-0730

2019-01-15

-

6 -

Testing the MLS at Routine Preventive Maintenance

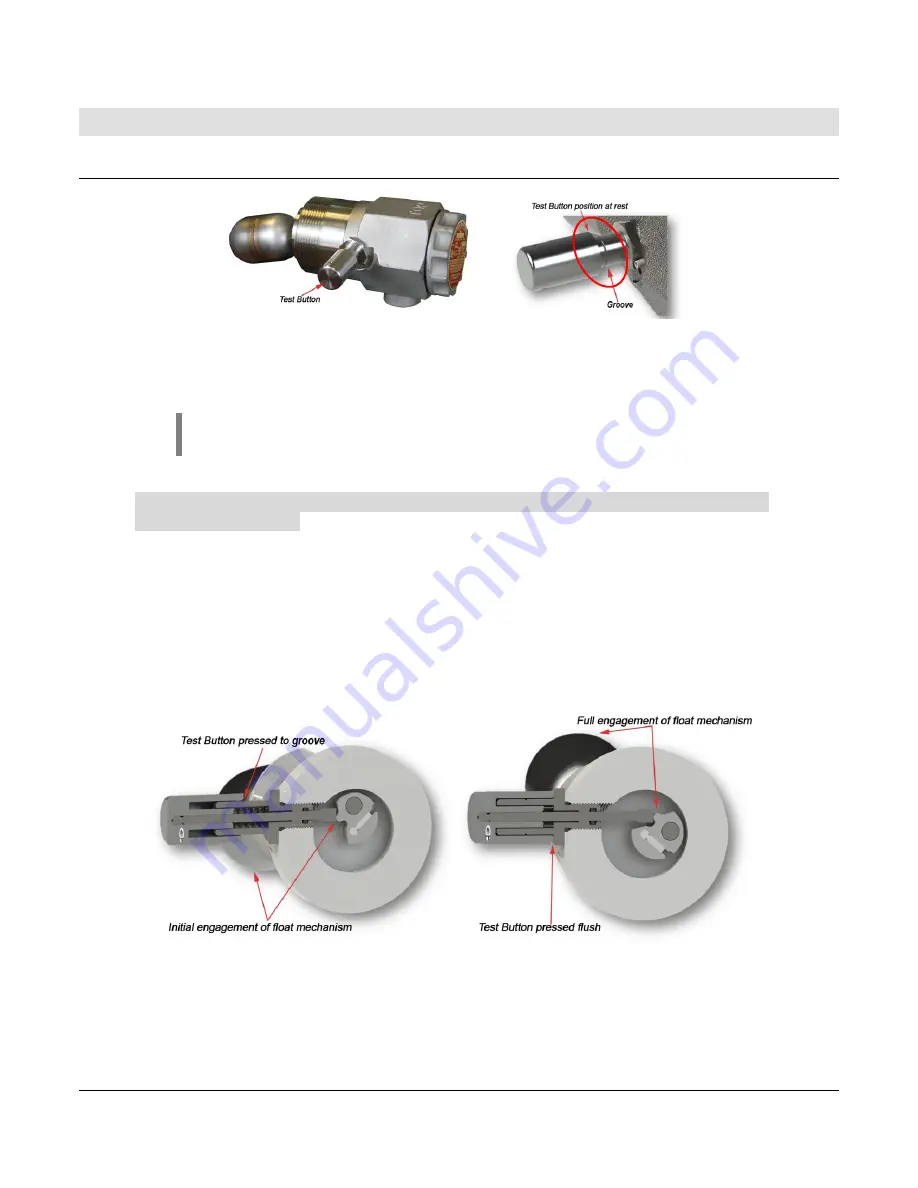

Test Button

– MLS TF Model Only

Considerations

The tank level can affect the test results. If the tank level is above the float, the float will already be in

the up position, and the test button won’t have anything to move. If the float is partially floating, you

might not be able to hear the float drop.

NOTE:

With a higher tank pressure, the Test Button will be noticeably harder to

push.

Test

IMPORTANT:

The panel should be in Test Mode if it is operating to avoid unintentional

shutdowns during test.

This procedure tests for float function; the complete mechanism including the magnetic activation of the

reed switch; and the wiring from the switch to the control panel.

1. If operating at time of testing, put the panel in Test Mode to avoid an unintentional shutdown.

2. Push the Test Button in while listening for the float to hit the top of the body.

3. Release the Test Button while listening for the float to hit the bottom of the body.

a. When you hear the float hitting the body as you press and release the button, the float is

attached and working properly.

b. If the float is gone, the counter balance will rotate to the faulted or high level position

causing the switch to trip. The MLS unit will have to be removed and repaired or

replaced.

c. As the test button is being pressed, the motion should be fairly smooth and consistent

through the entire travel of the button and return. If it is not, there is a problem with the

float mechanism, and the MLS unit will have to be removed and repaired or replaced.

Summary of Contents for MLS Series

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 16: ......