Section 15

00-02-0730

2019-01-15

-

7 -

Testing MLS Switch Manually

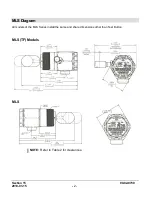

– MLS Models

We suggest using the FW Murphy magnetized screwdriver approach to test the micro-reed

switch and float position.

CAUTION:

Be sure to follow hazardous area electrical procedures.

The Principle of Test Method

The reed switch in the MLS is operated by an applied magnetic field. The magnetic field is

designed so that the switch will be actuated at a location further from the terminal under

normal working conditions. When the float is missing, the counter balance will drop, raising the

end where the float should be because of the weight of the counter balance. The movement of

the counter balance will bring the magnetic field to a lower position through the mechanism.

Using this approach can easily test the float status and operation of the switch.

Considerations

Be careful not to damage or short wires connected to the MLS either at the switch or the

annunciator or controller connection point (control panel).

Check terminal connections and wiring before replacing the cover of the MLS for proper

operation.

Test Preparation

1. Check the sight glass to make sure any liquid level is below the MLS. (If the float is

already raised by liquid, the test procedure may suggest the float is missing and that the

counter balance has forced the assembly into the high liquid level state.)

2. Make sure the area is non-hazardous, getting a hot work permit, for instance. This only

needs to be done if the circuit connected to the MLS is not intrinsically safe or non-

incendive.

3. Disconnect the wiring once it is de-energized to use a meter to perform the test, or use

the test function of the annunciator or controller to verify switch operation.

NOTE:

Manual testing is always used with the standard FW Murphy MLS

Series Liquid Level Switches and can be used on any MLS model.

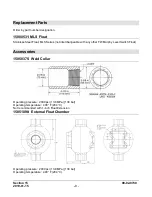

MLS Model (standard)

MLS TF Model (Optional)

Summary of Contents for MLS Series

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 16: ......