10

SHARPENING wEDGE

When the machine has been in use for a long time, or

as necessary, sharpen the wedge with a fine-toothed

file then carefully smooth any possible uneven areas on

the cutting surface.

MOVING AND TRANSPORT

Before movement or transport of the machine remove

the electrical cable from the power source: wait until

the machine's operation has stopped completely; allow

the machine to cool; and wind up the electrical cable

and attach it.

CAUTION: BEFORE MOVING THE LOG BUSTER,

MAKE SURE THE BLEED SCREw IS TIGHTENED

TO AVOID OIL LEAKING.

When you want to move the log splitter a short

distance, lift the front handle such that the front part of

the machine rises up and the wheels touched the

ground. Then push or pull the machine by moving

backwards or forwards. Pay attention to uneven and/or

slippery surfaces.

STORAGE

Disconnect the log splitter from the mains supply.

Tighten the bleed screw.

Clean the unit down using a dry cloth.

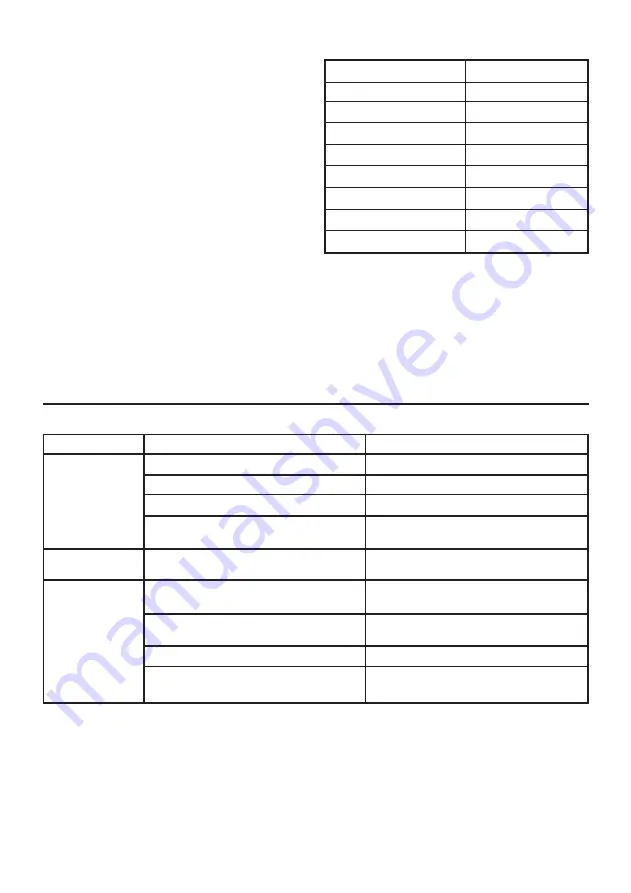

TECHNICAL SPECIFICATION

Voltage

230V - 50Hz

Motor

2200W S3 25%

Rated tonnage

7 Ton

IP rating

IP54

Maximum log length

520mm

Minimum log diameter

5mm

Maximum log diameter

320mm

Hydraulic pressure

18Mpa

Oil capacity

6.5L

TROUBLESHOOTING

PROBLEM

Fails to split logs.

The log splitter

moves jerkily.

Oil leaks around

cylinder ram or

from other points.

CAUSE

Log is improperly positioned.

Wedge cutting edge is blunt.

Oil leaks.

Unauthorised adjustment was made on

max. pressure limiting screw.

Excessive air in the hydraulic system.

Air sealed in hydraulic system while

operating.

Bleed Screw is not tightened before moving

the log splitter.

Oil Drain Bolt is not tight.

Hydraulic Control Valve Assembly and / or

seal(s) worn

CAUSE

Refer to "Positioning The Log" section.

Refer to "Sharpening Wedge" section.

Contact the dealer.

Contact the dealer.

Check oil level for possible oil refilling.

Contact the dealer

Loosen Bleed Screw by 3-4 turns before

operating the log splitter.

Tighten the Bleed Screw up before moving

the log splitter.

Tighten the Oil Drain Bolt.

Contact the dealer.

Summary of Contents for FXA501577162

Page 2: ...2 3 1 2 1 4 9 5 12 11 10 7 6 8 13 14 ...

Page 3: ...3 2 3 2 1 ...

Page 4: ...4 4 5 6 7 ...

Page 27: ...27 ...