FYTTER |

WWW.FYTTER.COM

PAG- 36

11.

COMMON ERRORS / ERRORES COMUNES / ERREURS COMMUNES / GLI ERRORI PIU COMUNI / HÄUFIGE

FEHLER / VEELVOORKOMENDE FOUTEN

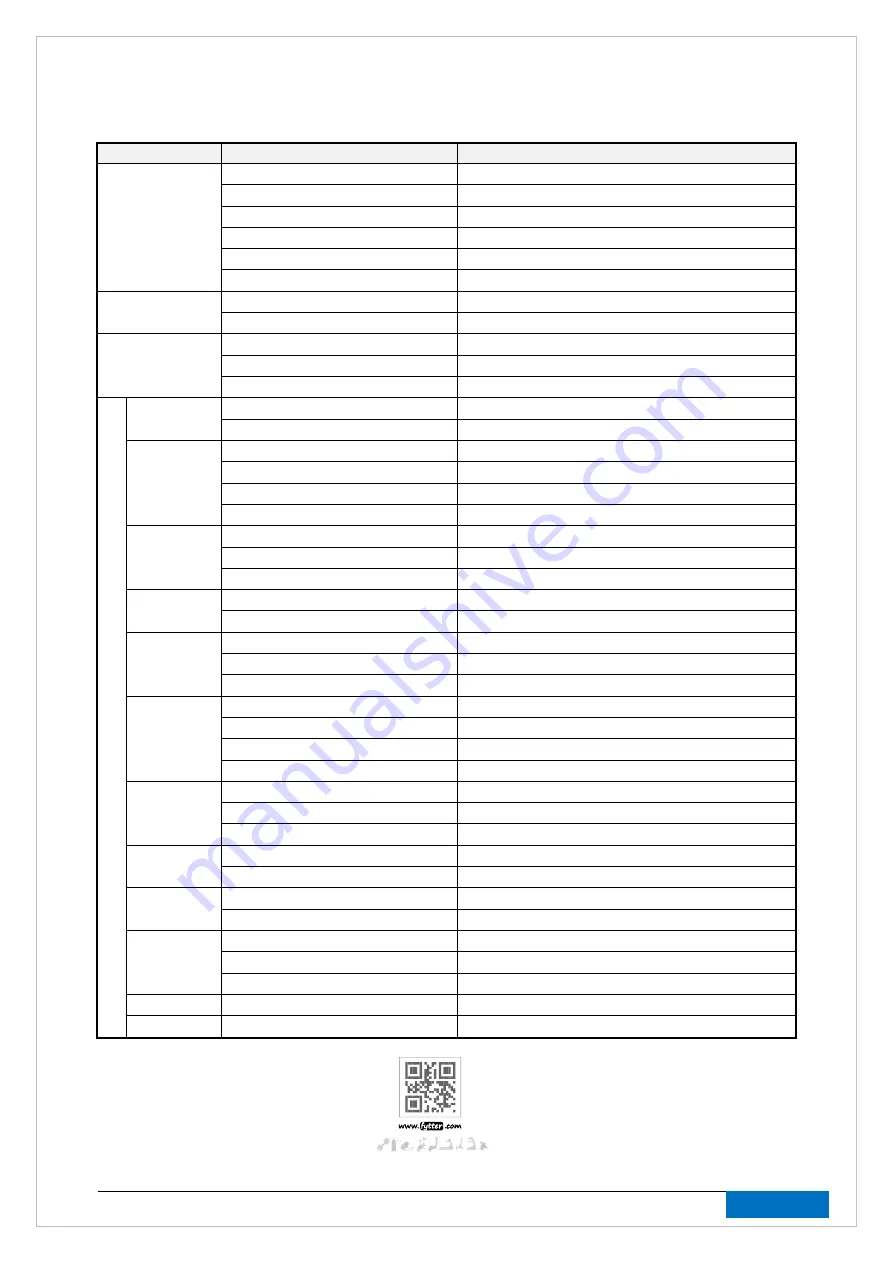

ERRO CODE

REASON

HOW TO SOLVE

NO DISPLAY

A) electricity not connected

Connect the electricity

B) power switch not turn on

Turn on power switch

C) pcb no power or broken

Press over-load protector or change new pcb

D) signal wire not connected

Re-connect signal wire or change new one

E) computer broken

Change new computer

F) background light broken

Check background light wire or change new one

NOT DISPLAY ALL

INFORMATION

A) display drive IC not inserted well

Re-insert IC,and re-weld it or change new one

B) EMI gasket slip, not well fastened

Re-assemble screen

NOT RUN

SMOOTHLY

A) driving position has resistance

Adjust driving position, or add some silicon oil

B) running belt too tight or too loose

Adjust the belt tension

C) pcb torque too big or too small

Ajust torque to right position

---OR----

(OR E00/E07)

A) safety key off

Put on safety key

B) magnetron not fixed well

Fix magnetron to right position

E01/E13

A) signal wire not well connected

Re-connect signal wire

B) signal wire broken

Change new signal wire

C) signal wire broken

Change new computer

D) pcb broken

Change new pcb

E02

A) motor wire not well connected, or open

circuit

Re-connect motor wire or change new motor

B) IGBT on pcb broken

Change new pcb

C) input voltage too low

Stop using, ask electrician to check

E03

A) speed signal wire not well connected,

or sensor broken

Re-connect speed signal wire or change new sensor wire

B) pcb broken

Change new pcb

E04

A) incline motor wire not well connected

Re-connect incline motor wire

B) incline motor broken

Change new incline motor

C) pcb broken

Change new pcb

E05

A) over-loaded

Turn off and re-start machine

B) driving position hinder

Adjust driving position, or add oil

C) motor short circuit

Change new motor

D) pcb burnt

Change new pcb

E06

A) motor wire not well connected

Re-connect motor wire

B) motor open circuit

Change new motor

C) motor idling

Re-assemble to test

E08

A) storage IC not well inserted

Re-insert IC, pay attention to pins

B) storage IC broken, or pcb broken

Change new IC, or change new pcb

E09

A) machine stand or not put evenly on

floor

Put evenly on floor

B) pcb broken

Change new pcb

E10

A) pcb torque too big

Adjust torque to right position

B) motor short circuit

Change new motor

C) driving position hinder

Adjust driving position, or add oil

E11

Input voltage too big

Stop using, ask electrician to check

E14

Input voltage too low

Stop using, ask electrician to check

Summary of Contents for RU005B

Page 1: ...REF RU005B R...

Page 20: ...FYTTER WWW FYTTER COM PAG 19 MANUAL MODE...