11

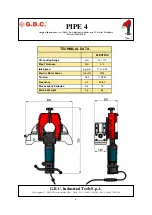

PIPE 4

Original Instructions

—

rev.2011

—

In compliance with the step 1.7.4 of the Machinery

Directive 2006/42/CE

G.B.C. Industrial Tools S.p.A.

Via Artigiani,17

–

25030 Torbiato di Adro (Bs)

–

Italia

–

Tel. + 39 030 7451154

–

Fax. + 39 030 73 56 629

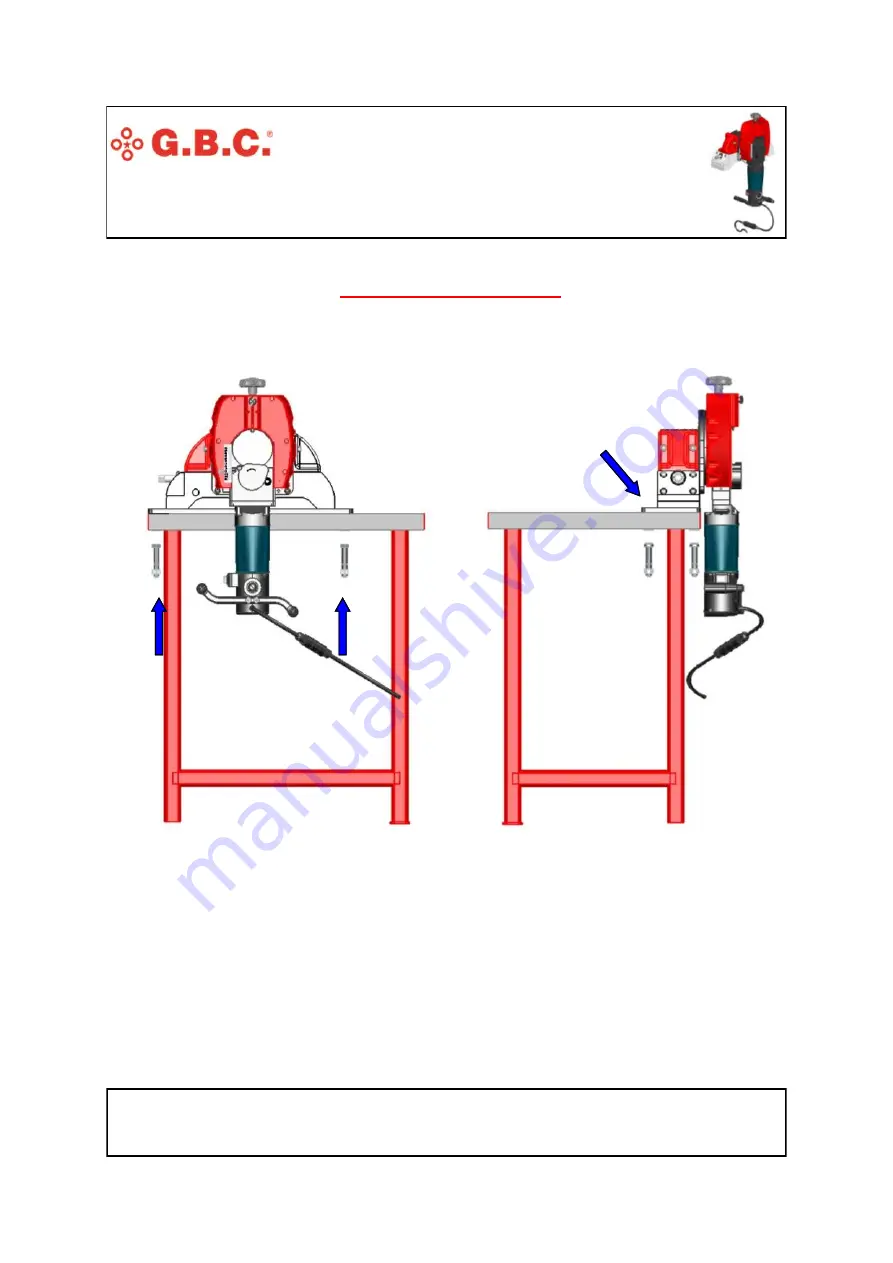

MACHINE SETUP

MACHINE SETUP

MACHINE SETUP

After the machine has been removed from its packaging, position it on top of a working

bench as shown in the picture. Once found a satisfactory position fix it in place with N° 4

M16 nuts with suitable length (not included).