Voltage of the oven:

check whether voltage of the equipment is the same of your

electric supply.

Wall socket:

socket where oven is to be connected should be a monophase or 3-phase

fix plug, dimensioned for the nomina l current of the protection circuit ( thermal-electrical

breaker), allowing full exemption of plug pins, without any clearances, so that sharp live parts

cannot be touched by human hand.

Socket wiring

: they should be rigorously in accordance with their respective compensations

as described in the Brazilian Standard NBR 5410 - ABNT ( Associação Brasileira de Normas

Técnicas - the Brazilian Association for Technical Standards ). Should you have any doubts

consult a specialized electrician.

Protection:

: at the circuit where oven is to be plugged to, there must be a thermal-electrical

circuit breaker as per the table below.

Ground wiring or Earth wire:

ground wire of your oven should be connected to an effective

earth cable, thus preventing from personal risks. Connection to a ground wire is necessary

under any voltage, and should not be connected to the neutral wire of the power supply, neither

to the hydraulic, gas or electrical piping, nor the faucets, etc. For a perfect ground wiring,

observe instructions under the Brazilian Standard NBR 5410 - ABNT, “Grounding Wire”.

Electrical extension cords or the like:

for no reason whatsoever should you connect any

other equipment to the same wall socket. That can cause an overload on the electrical supply

and/or bad contact. Overloads can cause prejudicial heating to insulation of the connections,

the terminals or surroundings of the conductors, and cause damages and it may even burn the

installations or the product.

It is the customer's responsibility if it is not possible to turn equipment on.

A CONNECTION TO A GROUND WIRING SYSTEM IS MANDATORY.

ELECTRIC SUPPLY

GAS TURBO OVEN

FTG 300-240-150-120

Model

Model

Dimensions:

FTG 120

FTG 120

FTG 150

FTG 150

FTG 240

FTG 240

FTG 300

FTG 300

1300

1300

1470

1470

580

660

1160

1000

Mono 110V

Mono 220V

Mono 110V

Mono 220V

1/4 Hp

1/4 Hp

1 Hp

1 Hp

15A

15A

15A

15A

1530

1610

1700

1770

820

820

860

860

980

980

940

940

Width

including

Switchboard

( mm )

Voltage

Width not

including

Switchboard

( mm ) )

Motor Power

Width

including

Base

( mm )

Protection Circuit

Breaker Recommended

Width not

including

Base

( mm )

Depth

( mm )

ATTENTION

GROUNDING WIRE: Installing ground wiring is mandatory for safety matters whatever

voltage of the product. Be careful! Ground wiring should not be connected to neutral wire

of the power supply. neither to water nor gas pipes, etc.

After observing recommendations described previously as for proper functioning of the

equipment, it will be ready to be used.

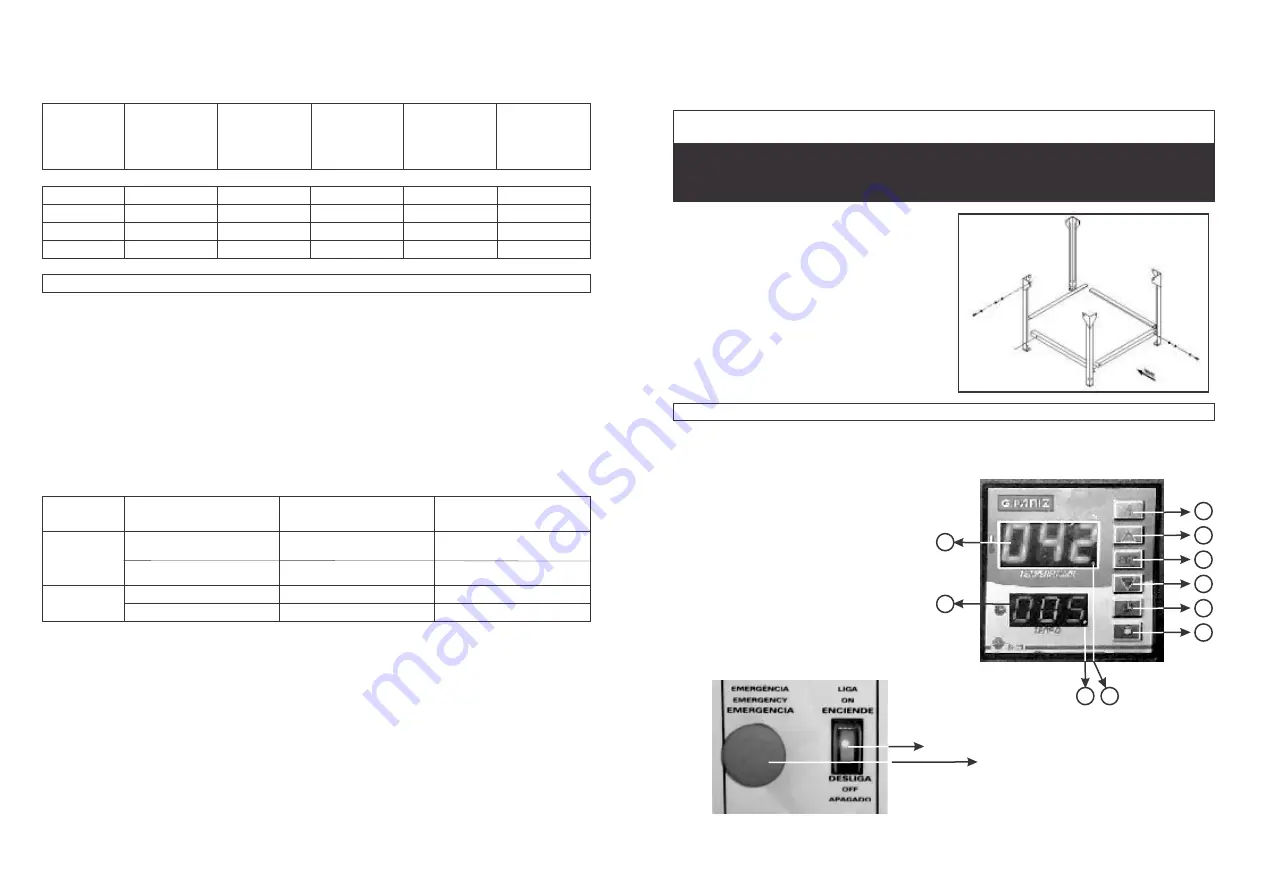

1) Lamp Switch Key

2) Timer Start Switch Key

3) Decrease Switch Key ( - )

4) (PGM) Programming

5) Increase Switch Key (+)

6) Steam Switch Key

7) Time Display

8) Temperature Display

9) Flame Indicator

10) Indicator for Time Decreasing

This supporting rack is supplied disassembled

only for models FTG 120 - FTG 150.

In order to assemble it correctly, follow steps

shown in the drawing below:

HOW TO PUT YOUR EQUIPMENT INTO OPERATION

GAS TURBO OVEN

FTG 300-240-150-120

5) ASSEMBLING THE SUPPORTING RACK

6

1

8

7

10

On / Off Switch key

Emergency Switch Key

9

2

3

4

5

18

23