GT-BH18External Booster Heater

Page 3

INSTALLATION

Before installation, please read this manual sent along with this booster heater, make sure

to verify the electrical power supply. Right after the packing is opened, please examine the

heater immediately for any damage caused during transportation. If any, please keep all the

packing materials, and inform the supplier within 3 days.

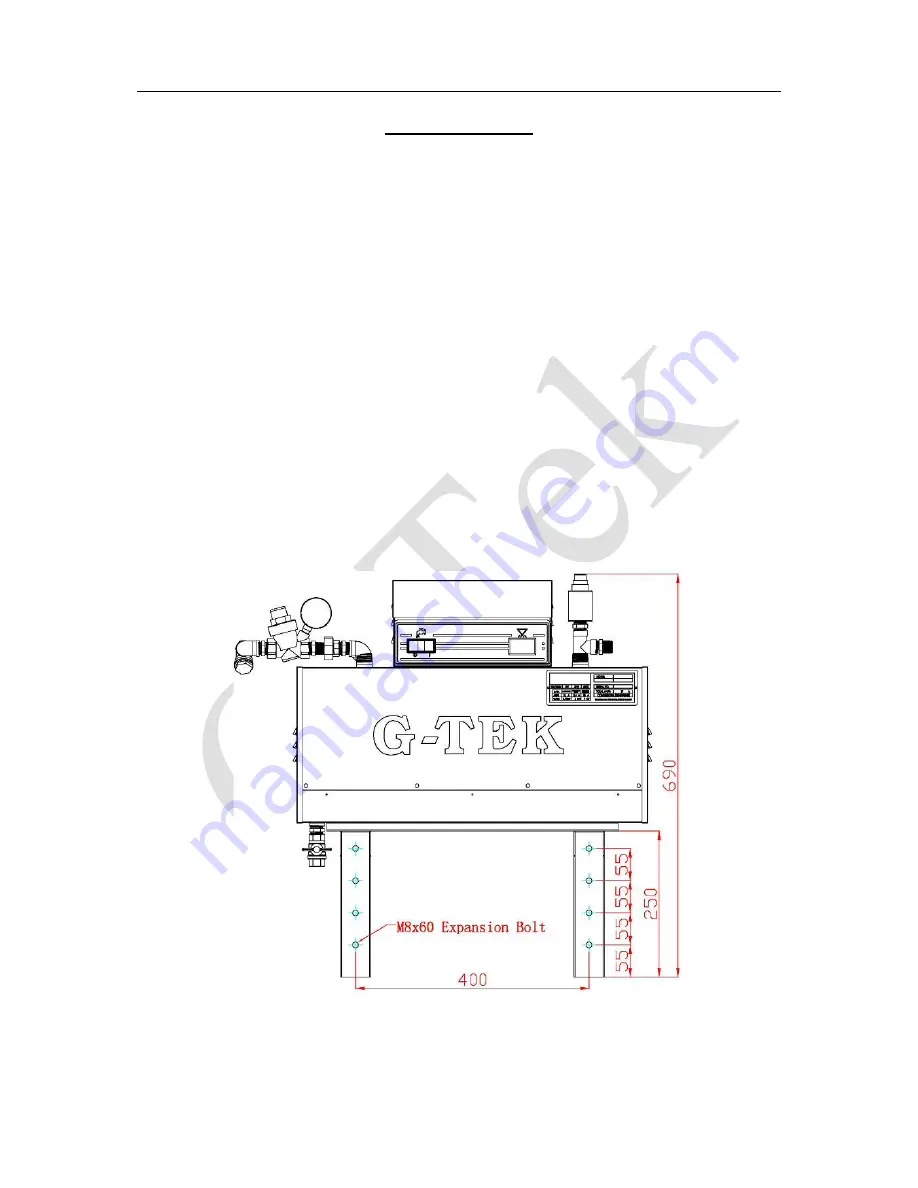

It is important to put the booster heater at the right place for operation. Before deciding a

proper position, please consider the connection of power supply, water supply, drainage,,

working tables and detergent dispenser (to be provided), as well as the required space for

maintenance and servicing, and ceiling height for opening the panel. Make sure the location

of the heater be avoided from water spillage and collide with any other kitchen equipments or

accessories such as racks and trolleys.

In the event that the booster heater be mounted on the wall, the given wall-mount must

be installed with 6 to 8 M8 x 80 expansion bolts. (Refer to Diagram 2 below)