Installation, operating and maintenance instructions

Radio locks PRIME OFFICE 2170 (EN 179) for toughened glass doors

9

0-45648-3E-0-GB, modif. 1, sheet 9/20, Mod. No. G24578, www.g-u.com 01/2011

4.2

Assembly instructions

radio lock PRIME OFFICE 2170 for toughened glass doors

The security features of this product are essential

for its conformity with EN 179.

Changes to the product, unless described in these

instructions, are not allowed!

Being a part of the mandatory marking to EN 179, the adhesive labels

attached to this product must not be removed. The CE label on the

cover must be clearly visible with the lock installed.

In the case of locks with uncoated covers, the CE label is enclosed in

the package loosely. Before assembly, it must be attached to the cover

visibly and reliably, preferably on the locking side.

Application range

8 mm, 10 mm and 12 mm toughened safety glass (ESG quality).

Cleaning of glass

Before assembling the lock, the glass has to be cleaned with a cleaning

agent leaving no residues. The glass must be absolutely clean and free

from grease and oil.

General assembly advice

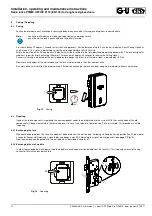

The glass door panel must be provided with boreholes as shown in

Fig. 6

.

For dimensions of lever handles see

Fig. 7

.

The length of the lever spindle must fit the thickness of the lock.

Glass thickness

8 mm

10 mm

12 mm

Lock thickness

38 mm

40 mm

42 mm

Assembly instructions

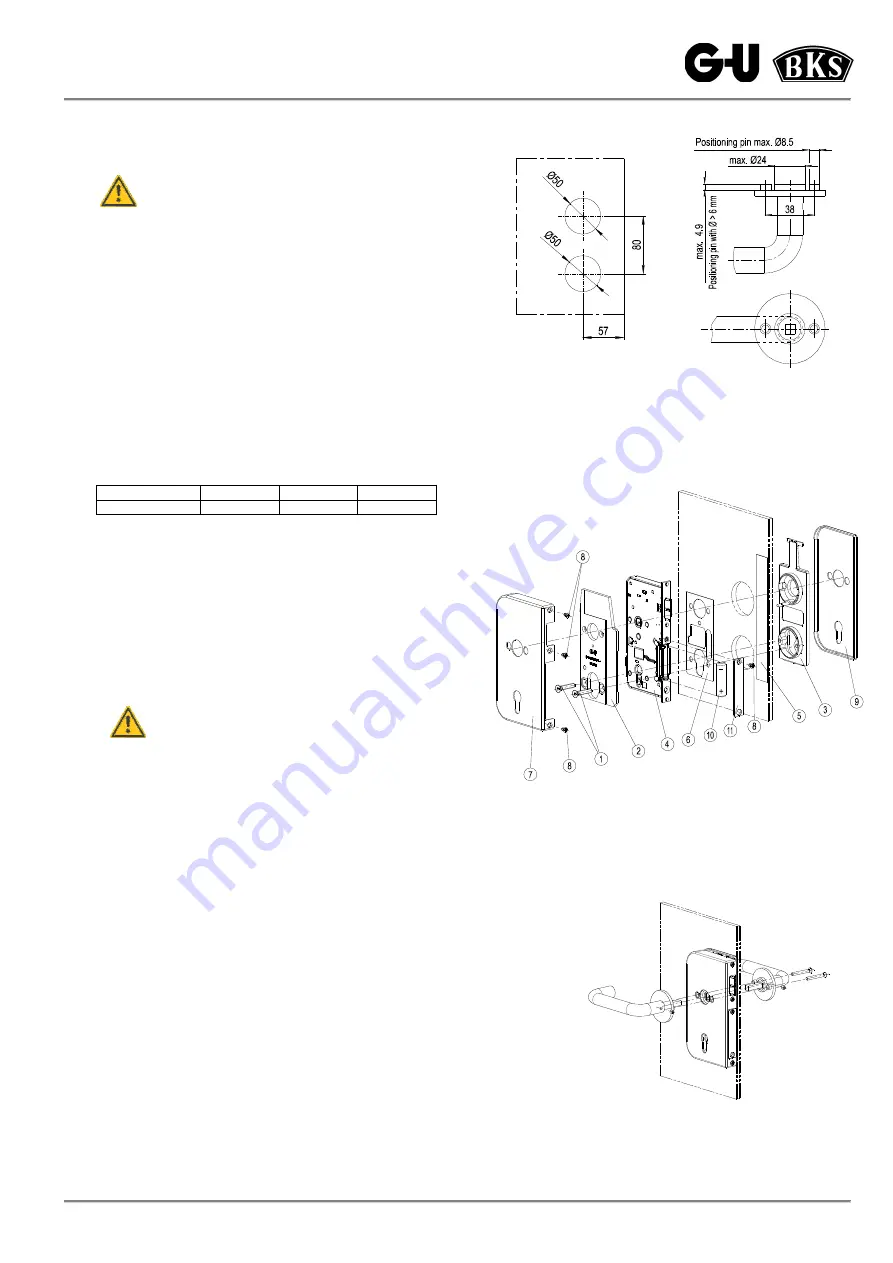

- Remove 2 countersunk screws M6x30 (1) using a hexagonal Allen

key size 4. Remove holding plates and clamping plates (2, 3).

- Apply self-adhesive film (5) on hinge side glass surface flush with

glass edge. The appropriate vertical position may be determined from

the position of the clamping plate on the other side. The adhesive film

will conceal the inside of the lock. Cut foil where protruding after lock

assembly.

- Mount the lock (4) to the glass door panel using screws (1), holding

plate (2), clamping plate (3), and gasket (6) as shown in

Fig. 8

.

Ensure that bevelled face of latch is directed towards glass.

Note: Ensure to accurately attach all protective gaskets

and glass protectors.

Negligent fastening may affect the lock function

or damage the glass!

Tightening torque

for clamping screws:

5 Nm

Inappropriate and excessive tightening or inaccurate positioning of

the lock may result in insufficient lock functioning.

- Attach hinge side cover (7) and fasten with countersunk screws

M4x6 (8) on front of lock (

Fig. 8

).

Engage the bore at the bottom of flat cover (9) on the pin of clamping

plate (3); The covers (7, 9) are clamped by the lever handles

additionally (

Fig. 9

).

- Install the locking cylinder. Insert the battery (10) with the positive

pole at the bottom (see chapter 5). Fit the battery case cover (11) and

fasten it with the cylinder fixing screw and the countersunk screw

M4x6 (8). Cylinder must be aligned accurately, otherwise it might be

rough-running.

- Mount fittings according to the instructions enclosed (

Fig. 9

).

The lever spindle must be axially aligned and fitted without tension.

Tightening torque

for rosette handle screws:

5 Nm

- Functional check:

The lock must be operable smoothly. Stiffness may be a sign of

inappropriate assembly or a distorted lock mechanism. The deadbolt

must enter into the strike plate freely and without friction at any time.

It may be necessary to adjust the cut-out of the strike to the particular

situation

Fig. 6:

Glass preparation

Fig. 7:

Dimensions

of lever handles

Hinge side

Opposite hinge side

Fig. 8:

Radio lock PRIME OFFICE 2170 for all-glass doors

Fig. 9:

Assembly of fittings