Installation, operating and maintenance instructions

Radio locks PRIME OFFICE 2170 (EN 179) for toughened glass doors

17

0-45648-3E-0-GB, modif. 1, sheet 17/20, Mod. No. G24578, www.g-u.com 01/2011

9.3

Maintenance

Emergency exit devices must be inspected for proper condition and functioning at least once a month.

The forces required to release the emergency exit device must be measured with a dynamometer and recorded. Major deviations from the

values recorded at initial installation are not acceptable.

The fittings must be checked for tight fit and wear. If necessary, fastening screws must be retightened and worn components exchanged by a

specialist company.

Ensure that strikes are not jammed or filled with dirt. Verify, if all components still comply with the originally specified, delivered and approved

components, and that no other locking device has been mounted to the door subsequently.

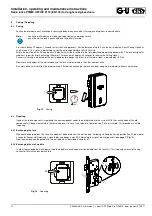

All locking and moving components of the exit device must be greased with acid-free lubricant (e.g. LUMO special grease 8559/1 from

Gmelin) at least once a year or more frequently depending on the stress. The rear of the latchbolt must be greased once a year at

least.

The radio lock PRIME OFFICE 2170 is operated with a special 3.6 V AA battery which offers a performance of 150,000 cycles at continuous

operation. In order to ensure the reliable functioning of the lock, it is necessary that the battery should be exchanged as soon as one of the

two low-battery alarm levels is reached (see chapter 3) or after 2 years (for approved battery types see chapter 1.1 Technical specifications

Power supply).

9.4

Cleaning

Clean covers exclusively with a soft cloth using a mild, ph-neutral cleaning agent in diluted form. Never use agressive, acidic detergents or

scouring agents, or agents containing corrosive ingredients.

9.5

Duty to inform and to instruct

In order to comply with the informational and instructional duties prescribed by the German Product Liability Act, the following documents and

services are made available to specialist dealers, locksmiths, architects, planners, fabricators and end users upon request:

- Catalogues, brochures, tender specifications, quotation documents,

- EN 12209, DIN 18251, DIN 18252, EN 179, etc. (exclusive distribution of DIN standards by Beuth-Verlag GmbH, Berlin),

- Assembly, operating and maintenance instructions,

- Technical support directly from us or from our consulting field service.

- For the appropriate selection, installation, operation, and maintenance of locks and fittings,

architects and planners are advised to request from us and observe all required product information,

specialist dealers are advised to follow the appropriate product information and references in the catalogues, and to request all necessary

instructions from us in order to forward them to the fabricators/installers.

fabricators/installers are advised to follow all product information, and to request from us operating and maintenance instructions in order

to hand them out to customers and users.