5

B

B

A

C

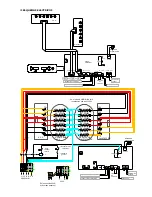

4.5 CLEARANCES

The clearances around the boiler as shown above must be

observed for correct operation.

A minimum of 200mm clearance must be maintained

underneath the boiler to allow replacement of the heating

elements if required. A minimum of 500 mm clearance must

be maintained in front of the boiler to enable easy access for

servicing.

Ensure sufficient space to make all water connections including

the outlet pipes for the heating safety valve which should be

routed to a suitable discharge point.

A: 50 mm

B: 10 mm

C: 200 mm

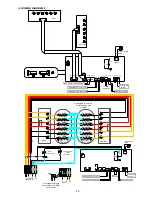

4.6 MOUNTING BRACKET

Mark the hole positions using the wall bracket as a template

per the diagram.

Fit bracket securely onto wall before lifting appliance into

position. Drill the holes and fit the bracket ensuring it is

level using suitable high strength screws, with appropriate

plugs or fixings, minimum M10 size.

Always use assistance if required. Wear suitable cut resistant

gloves when handling the appliance. Ensure safe lifting

techniques are used. Do not lift the appliance by attached

pipe-work or components. When lifting the boiler ensure

that the fixing elements and the wall have a sufficient load-

bearing capacity. Check the quality of the wall.

4.7 WATER CONNECTIONS

CAUTION: The hydraulic connections must be carried out respecting the flow and return marked on the

boiler.

CAUTION: When tightening or loosening threaded connections, always use suitable tools as open-end

spanners. Do not use pipe wrenches, extensions or unsuitable tools that may cause damage or water leaks.

Install purges in the radiators and high points of the installation.

Heating Flow & Return

These connections are ¾ “ for connection to 22mm pipe. Service valves should be installed at this position to

allow the boiler to be isolated for maintenance without the need to drain the entire system. The valves should be

of sufficiently large bore so not to restrict the heating circulation.

Single pipe heating systems are not recommended only a twin-pipe heating system should be used.

i