Technical Information

WIRING

Basic electrical connections are illustrated in

Diagram

2 (for the

ESD-5550

,

ESD-5555

and the

ESD-5570

) and

Diagram 3

(for the the

ESD-5556

only). Actuator and battery connections to

Terminals A, B, E,

and

F

should be #16 AWG (1.3 mm

2

) or larger. Long cables require an increased

wire size to minimize voltage drops. The battery positive (+) input,

Terminal F,

should be fused for

15 amps as illustrated.

Magnetic speed sensor wires connected to

Terminals C

and

D

MUST BE TWISTED AND/OR

SHIELDED for their entire length. The speed sensor cable shield should ideally be connected as

shown in

Diagram 2

or

3.

The shield should be insulated to insure no other part of the shield

comes in contact with engine ground, otherwise stray speed signals may be introduced into the

speed control unit. With the engine stopped, adjust the gap between the magnetic speed sensor

and the ring gear teeth. The gap should not be any smaller than 0.020 in. (0.45 mm). Usually,

backing out the speed sensor 3/4 turn after touching the ring gear teeth will achieve a satisfactory

air gap. The magnetic speed sensor voltage should be at least 1 VAC RMS during cranking.

ADJUSTMENTS

Before Starting Engine

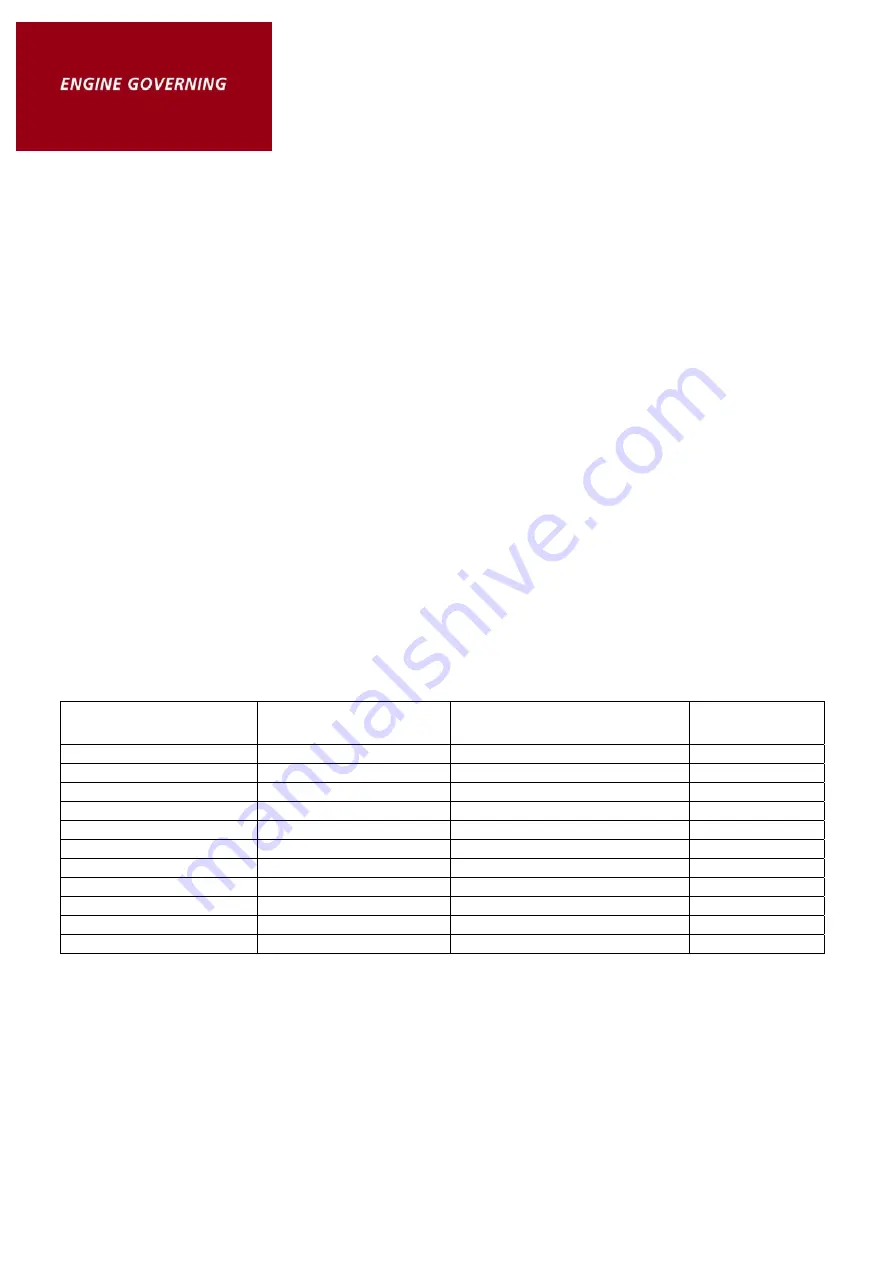

Before starting the engine, check and/or adjust the POTs/switches to the following settings. See

Table 2

for the factory presets.

Adjustment/Switch

Potentiometer/Switch

Setting

Applicable

Units

SPEED

25° turn

1470 Hz 1/- 50 Hz w/min trim

all

GAIN

270° turn

50%

all

STABILITY

270° turn

50%

all

DROOP

270° turn

0% (CCW)

all

IDLE

270° turn

1075

±

75 Hz

all

STARTING FUEL RAMP

270° turn

100% (CW) Maximum Fuel

all

SPEED RAMP

270° turn

0% (CCW) Fastest

all

OVERSPEED

25° turn

100% (CW) Highest

all

CRANK TERMINATION

25° turn

0% (CCW) Lowest

ESD-5556 only

SW1 Lead Circuit

switch

ON

all

SW2 Soft Coupling

switch

OFF

all

Start Engine

The speed control unit governed speed setting is factory set at approximately engine idle speed.

(1000 Hz., speed sensor signal) Crank the engine with DC power applied to the governor

system. The governor system should control the engine at a low idle speed. If the engine is

unstable after starting, turn the

GAIN

and

STABILITY

adjustments

CCW

until the engine is

stable.