1

Governors America Corp. © 2020 Copyright All Rights Reserved

ESD5550-5570 Series Speed Control Unit

9-2020-E

PIB1003

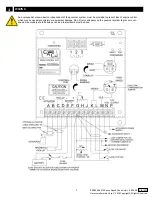

ESD5550 & ESD5570 Series

Speed Control Unit

2

SPECIFICATIONS

Performance

Isochronous / Steady State

Stability

± 0.25 % or better

Speed Range / Governor

1 K - 7.5 K Hz continuous

Speed Drift with Temperature

±1 % MAX

Idle Adjust CW

60 % of set speed

Idle Adjust CCW

Less than 1200 Hz

Droop Range

1 - 5 % regulation

Droop Adjustment MAX

(K-L Jumpered)

400 Hz, ±75 Hz per 1 A change

Droop Adjustment MIN

(K-L Jumpered)

415 Hz, ±75 Hz per 1 A change

Remote Variable Speed Range

500 - 7.5 Hz or any part thereof

Speed Trim Range

± 200 Hz

Terminal Sensitivity J

L

N

P

100 Hz ±15 Hz/V @ 5.0 kΩ Impedance

735 Hz ±60 Hz/V @ 65 kΩ Impedance

148 Hz ±10 Hz/V @1 MΩ Impedance

10 V DC Supply @ 20 mA MAX

InPUT / oUTPUT

Operating Voltage

12 VDC or 24 VDC (Transient and

Reverse Voltage Protected)*

Polarity

Negative Ground (Case Isolated)

Power Consumption

50 mA continuous

plus actuator current

Actuator Current Range at 77 °F

(25 °C) - Inductive Load

Minimum 2.5 A

10 A Peak**

Speed Sensor Signal

0.5 to 120 V RMS

Speed Switch Relay Contacts

(N.O. and N.C.)

10 A

1

INTRODUCTION

reLIaBILITY

Vibration

5 g @ 20 - 500 Hz

Testing

100% Functional Testing

envIronmenTaL

Ambient Temperature Range

-40° to 85 °C (-40° to 180 °F)

Relative Humidity

up to 95 %

Shock

20 g @ 11 ms

All Surface Finishes

Fungus Proof, Corrosion Resistant

comPLIance / STanDarDS

Agency

CE, RoHS, Lloyds Register,

DNV/GL, Bureau Vertas

PHYSIcaL

Dimension

See Section 3, Installation

Weight

1.8 lbf (0.82 kgf)

Mounting

Any position, vertical preferred

The ESD5550/5570 series speed control unit is an all electronic device de-

signed to control engine speed with fast and precise response to transient

load changes. This closed loop control, when connected to a proportional

electric actuator and supplied with a magnetic speed sensor signal, can con-

trol a wide variety of engines in an isochronous or droop mode. Designed

for high reliability and built ruggedly to withstand the engine environment.

ESD5550/5570 Series speed control unit features include:

•

Simple installation

•

Starting Fuel and Speed Ramping adjustments to minimize engine ex-

haust smoke prior to attaining engine operating speed

•

Adjustable droop and idle operation

•

Inputs for accessories used in multi-engine or special applications

•

Protection against reverse battery voltage, transient voltages, acciden-

tal short circuit of the actuator and fail safe design in the event of loss of

speed sensor signal or battery supply.

•

Light Force Actuation (ESD5570 only)

The ESD5550/5570 Series speed control unit is compatible with all GAC

proportional actuators except the ACB2001 electric actuator. When paired

with a GAC ADC100 Series electric actuator, DROOP adjustment range is

less due to the ADC100’s low current demand.

* Protected against reverse voltage by a series diode. A 15 amp fuse must be installed in

the positive battery lead.

** Protected against short circuit to actuator (shuts off current to actuator), unit automati

-

cally turns back on when short is removed.