5

Governors America Corp. © 2020 Copyright All Rights Reserved

ESD5550-5570 Series Speed Control Unit

9-2020-E

PIB1003

5

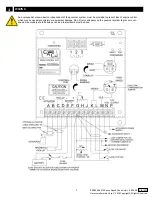

ADJUSTMENTS

Before starting the engine, check and/or adjust the potentiometer and following settings as desired.

Before STarTInG THe enGIne

The speed control unit governed speed setting is factory set at approximately engine idle speed 1000 Hz., speed sensor signal).

Crank the engine with DC power applied to the governor system. The governor system should control the engine at a low idle speed. If the

engine is unstable after starting, turn the GAIN and STABILITy adjustments CCW until the engine is stable.

STarTInG THe enGIne

The overspeed relay output terminals offer both normally open and normally closed contacts.

1. When the engine is running at the desired speed, push and hold the TEST button.

2. Rotate the OVERSPEED adjustment CCW until the red OVERSPEED LED lights and the

relay energizes. Current to the actuator will be removed and the engine will shut off.

3. Release the TEST button.

4. After the engine stops, press the RESET button or remove battery power.

5. Restart the engine and it will return to the original speed setting.

The overspeed function is now set to approximately 10% above the requested speed.

1 2

ON

STABILITY

GAIN

SPEED

OVERSPEED

aDJUSTInG overSPeeD

aDJUSTmenT / SWITcH

PoTenTIomeTer / SWITcH

facTorY SeTTInG

noTeS

SPEED

25 turn

1470 Hz ± 50 Hz w/ min. trim

GAIN

270° turn

50%

Middle position

STABILITy

270° turn

50%

Middle position

DROOP

270° turn

0% (CCW)

IDLE

270° turn

1075± 75 Hz

STARTING FuEL RAMP

270° turn

100% (CW) Maximum Fuel

SPEED RAMP

270° turn

0% (CCW) Fastest

OVERSPEED

25 turn

100% (CW) Highest

SW1 Lead Circuit

switch

ON

SW2 Soft Coupling

switch

OFF

The engine’s exhaust smoke at start-up can be minimized by completing the following adjustments:

1. Place the engine in idle by connecting Terminals M & G.

2. Adjust the IDLE speed for as low a speed setting as the application allows.

3. Adjust the STARTING FuEL CCW until the engine speed begins to fall. Increase the STARTING FuEL slightly so that the idle speed

is returned to the desired level.

4. Stop the engine.

STarTInG fUeL aDJUSTmenT

IDLe SPeeD SeTTInG

If the IDLE speed setting was not adjusted as detailed in Starting Fuel Adjustment section, then complete the following:

1. Place the optional external selector switch in the IDLE position.

2. Adjust the IDLE CW yo increase the idle speed set point.

3. When the engine is at idle speed, the speed control unit applies droop to the governor system to ensure stable operation.