4

REV. 3/15

GB731 S/N: 1702 AND ABOVE

PLEASE CONTACT GAGE BILT FOR ALL OTHER SERIAL NUMBERS.

Image may not reflect actual tool

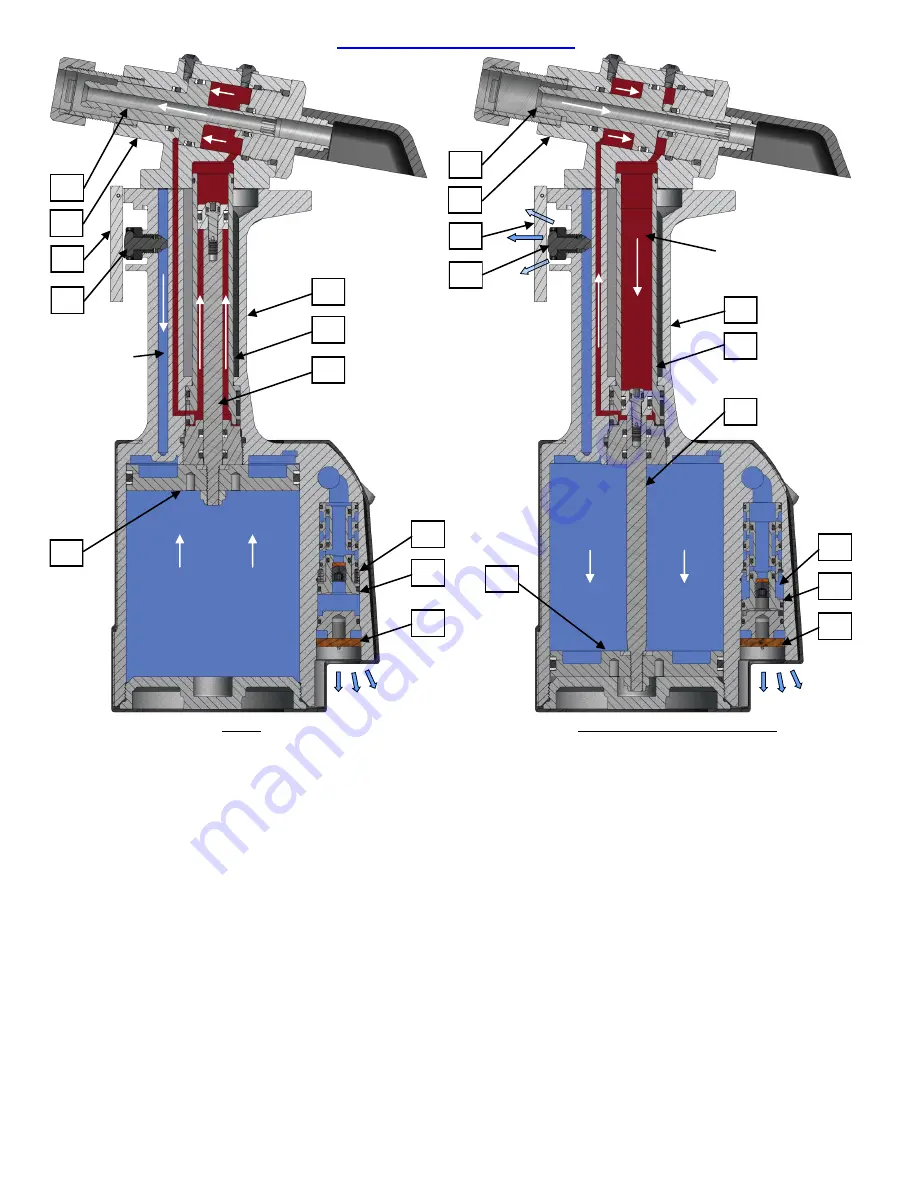

PRINCIPLE OF OPERATION

1

Air exhaust

Air actuator

pathway

3

5

10

11

9

8

7

air

air

air

air

Hydraulic oil

10

11

9

8

7

5

View 1

View 2 air actuator assy depressed

4

6

2

6

Air exhaust

1

3

4

2

1. When compressed air is connected to the tool (view 1) the air* fills the air actuator assy (4) pathway and is kept in check behind

the valve spool assy (10).

2. When the actuator lever assy (3) is depressed (view 2) air escapes through the air actuator assy (4) causing a drop in pressure.

The valve spring (9) is then released opening the valve spool assy (10). The compressed air is then ported by the valve spool

assy (10) to the air piston assy (5) pushing it downward. Air behind the air piston assy is exhausted through the muffler (11).

3. The downward movement of the air piston assy (5) pulls down on the piston rod assy (8). The hydraulic oil in the power cylinder

(7) is then pushed downwards and moves through the ports in the bottom of the power cylinder (7) up into the port in the handle

assy (6) and then up into the head cylinder (2).

4. The hydraulic oil pushes the piston (1) backwards while the internal components of the attached nose assembly are also moving

with the piston to start the fastener installation thus, transferring 4,800 lbs. (21.35 kN) of pulling force on the nose assembly and

fastener.

5. As this action is taking place the hydraulic oil behind the piston (1) is forced down into the power cylinder cavity as the piston

rod assy (8) moves downward.

6. When fastener installation is complete, the actuator lever assy (3) is released (view 1) air pressure builds again in the air actua-

tor assy (4) porting, compressing the spring (9). This action closes the valve spool assy (10) and redirects the air to the bottom

of the air piston assy (5) pushing it upwards. Air above the air piston assy is exhausted out through the muffler (11).

7. This action moves the piston rod assy (8) upwards pushing the hydraulic oil in the power cylinder (7) cavity upwards and

against the rear of the piston (1). This action generates a return force on the nose assembly pushing it off the installed fastener.