20

GB731SHV5/LB68 INSTALLATION TOOL: SERIAL # 1001 & ABOVE

CONTACT GAGE BILT FOR ALL OTHER SERIAL NUMBERS.

2/19 REV. 1/23

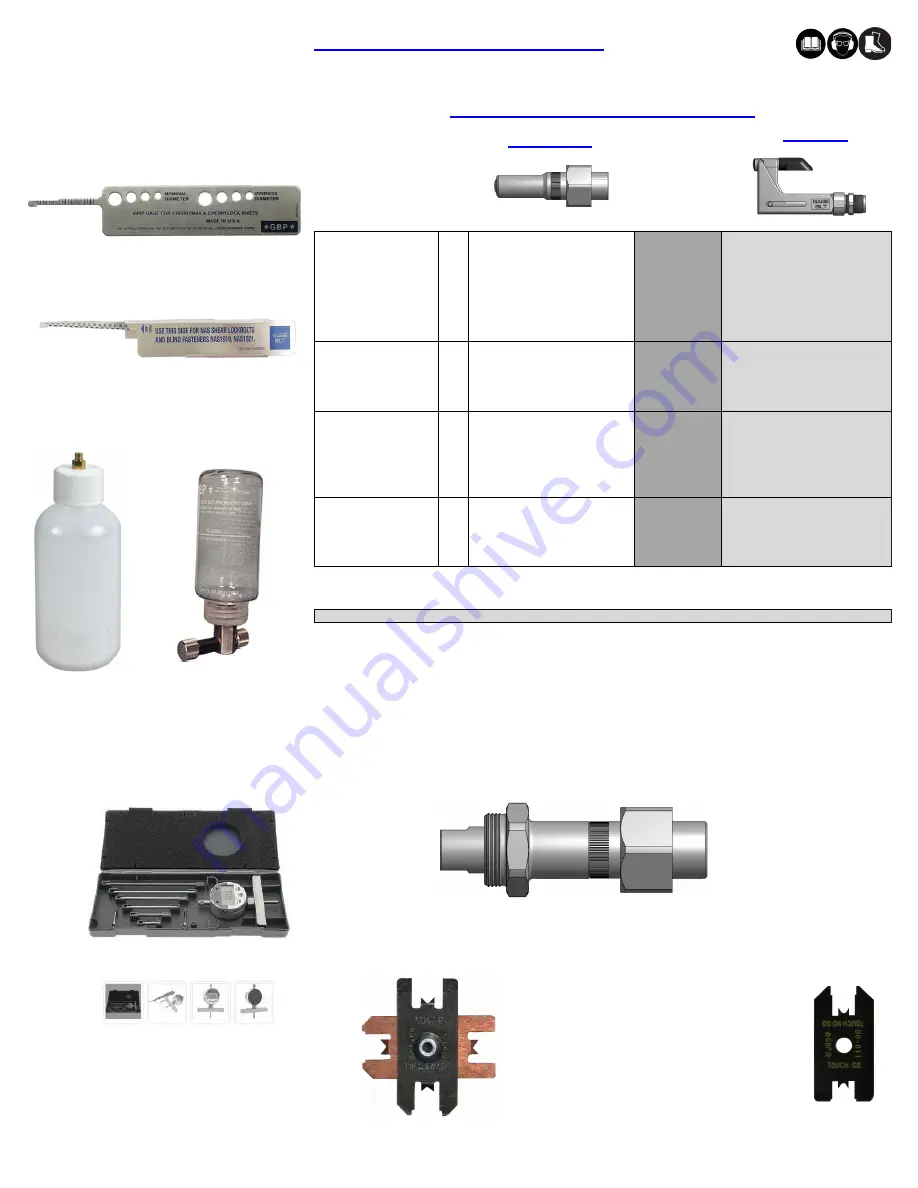

Adapter Assembly

#751204

Adapts GB204 series nose assemblies to

GB731 installation tool.

(Sold Separately)

Grip Gage #GB105093

For NAS LOCKBOLTS and blind fasteners

(Sold Separately)

Gage Bilt also supplies pin & collar swage

inspection gages to certify swage installation.

(Sold Separately)

Grip Gage #269G3

For CHERRYMAX® and

CHERRYLOCK® rivets

(Sold Separately)

Air Bleeder

Assembly

#704153

(Sold Separately)

Fill Bottle

#745263

(Sold Separately)

NOSE ASSEMBLY SELECTION CHART

**OFFSET

(Sold Separately)

STRAIGHT

(Sold Separately)

FASTENER

DIA.

*RIGHT ANGLE

3/16

LGP06-2480-10

LGP06-2480-20

LGP06-204C-25OS

LGP06-204D-30OS

LGP06-2480-45

LGP06-204C-34OS

7/32

LGP07-731-10

LGP07-731-20

LGP07-204C-25OS

LGP07-204C-34OS

LGP07-731-45

LGP07-204C-30OS

1/4

LGP08-2480-10

2

LGP08-2480-20

2

LGP08-204C-25OS

LGP08-204D-30OS

LGP08-2480-45

2

LGP08-204C-34OS

5MM

MLGP5-730B-10

MLGP5-2480-20

MLGP5-204C-25OS

MLGP5-204D-30OS

MLGP5-2480-45

MLGP5-204C-34OS

6MM

MLGP6-730B-10

2

MLGP6-2480-20

2

MLGP6-204C-25OS

MLGP6-204D-30OS

MLGP6-2480-45

2

MLGP6-204C-34OS

3/16

NAS06-730B-10

NAS06-2480-20

NAS06-204C-25OS

NAS06-204D-30OS

NAS06-2480-45

NAS06-204C-34OS

1/4

1

NAS08-352-10

2

NAS08-2480-20

2

NAS08-204C-25OS

NAS08-204D-30OS

NAS08-2480-45

2

NAS08-204C-34OS

5 MM

MGP5-730B-10

MGP5-2480-20

MGP5-204C-25OS

MGP5-204D-30OS

MGP5-2480-45

MGP5-204C-34OS

6 MM

MGP6-730B-10

2

MGP6-2480-20

2

MGP6-204C-25OS

MGP6-204D-30OS

MGP6-2480-45

2

MGP6-204C-34OS

1) NOT FOR TENSION ALLOY OR TITANIUM

2) THE 731355 INSERT ON TOOL MUST BE REMOVED WHEN USING 1/4" OR 6mm NOSE ASSEMBLIES

STRAIGHT

**OFFSET

LGP® LOCKBOLT

LGPL2SC-V BACB30VM

LGPL18SC-V BACB30XT

LGPL4SC-V ABS0548

LGPL2SP-V BACB30VN

LGPL4SP-V ASNA2392

LGPL8SC-V BACB30WD

LGPL9SC-V BACB30WB

LGPL9SP-V BACB30VY

BACB31N BACB31P

NAS and GP® SHEAR/TENSION

LOCKBOLTS

BACB30TY BACB30UA

BACB30TZ BACB30UB

BACB30DY BACB30GX

BACB30DX BACB30GP

BACB30GO BACB30GY

BACB30GW

**ALL OFFSET 204 SERIES NOSES REQUIRE 751204 ADAPTER.

GAGE BILT CERTIFIES THE GB731SHV5/LB68 WILL INSTALL THE ABOVE FASTENERS

LGP ®, M LGP ®, M GP ®, A ND GP ® A RE REGISTERED TRA DEM A RKS OF HOWM ET A EROSP A CE.

NOTE: THE LAST 2 DIGITS OF THE NOSE ASSEMBLY REPRESENTS THE LENGTH THE NOSE EXTENDS FROM THE TOOL I.E. -20 = 2.0 INCHES

1/19 REV 5/22

MGP®

(MILLIMETER)

LOCKBOLT

MLGP®

(MILLIMETER)

LOCKBOLT

GB731SHV5

-

LB68 ACCESSORIES

Approved for use on Gage Bilt CE installation tools and/or other manufacturer

’

s CE approved tools of similar design.

(Sold Separately)

Tool Stroke Depth Gage

#A

-

1935

(Sold Separately)

Image may not reflect actual gage