5

REV. 2/14

WARNING:

DO NOT CYCLE TOOL WITHOUT AIR BLEEDER, OR THE SCREW AND STAT-O-SEAL, INSTALLED IN TOOL HEAD.

SEVERE PERSONAL INJURY MAY RESULT.

CAUTION:

BEFORE FILLING HANDLE, AIR PISTON SHOULD BE ALL THE WAY DOWN.

To replace a small amount of oil in the tool, connect tool to air line, to ensure power piston is at top of stroke. Follow steps 11-19

below. Should it become necessary to completely refill the tool (such as would be required after tool has been dismantled and

reassembled), take the following steps:

1. Ensure air piston ass’y (744121) is at the bottom of stroke by pushing piston rod ass’y (745344) down. Piston ass’y (204203)

should be at end of stroke.

2. Fill power cylinder (745331) and oil passage to the top, (where S832 sits).

3. Place gasket (745124) and o'ring (S832) on top of the handle (744129).

4. Install adapter-handle (745303), with swivels (S533) attached, carefully install screws (A-928), tighten evenly. Apply Loctite® 242 to

all cap screws

5. With hydraulic hoses (A-317) attached to cylinder (204300) , attach hydraulic hoses (A-317) to adapter-handle (745303).

6. Stretch tool out horizontally and lay flat on table or floor.

7. Attach fill bottle assembly (745163) to bleeder hole that leads to #2 hole on manifold handle.

8. Attach bleeder bottle (704153), to the pressure side, marked "P", on the rear of cylinder (204300).

9. Squeeze bleeder bottle 745163 on manifold-handle until no air rises into bleeder bottle (704153). Remove bleeder bottle (704153)

and install button-head cap screw (402482) and stat-o-seal (S572).

CAUTION:

Do not cycle tool without screws or bleeder bottle

Installed in tool.

10. Repeat steps 7-9 using the return pressure holes (the bleeder hole leading to hole #3 on manifold-handle and hole marked "R" on

rear of cylinder (204300).

11. Stand handle (744129) on floor, and stretch hose assembly upward on a table or bench laying head cylinder (204300) flat on it’s

side.

12. Connect tool to air, slowly loosen screw marked #2 on the manifold handle (CAUTION TOOL IS UNDER PRESSURE) let oil SEEP

out. Remove screw and attach bleeder bottle (704153). Cycle 10 times.

13. Remove bleeder bottle (704153) and install button-head cap screw (402482) and stat-o-seal (S572).

14. With tool connected to air slowly loosen screw, marked “P” on back of cylinder (CAUTION TOOL IS UNDER PRESSURE) let oil

seep out. Remove screw and attach bleeder bottle 7(04153). Cycle 10 times.

15. Remove bleeder bottle (704153) and install button-head cap screw (402482) and stat-o-seal (S572).

16. Hold actuator down until piston ass’y (204203) is at end of stroke, disconnect air.

17. Slowly loosen screw marked R. (back of cylinder). Remove screw and manually push piston to full rear position.

CAUTION:

oil

may bleed from oil port. Attach bleeder bottle (704153) connect tool to air and cycle tool 10 times.

18. Hold actuator down until piston ass’y (204203) is at end of stroke. Disconnect air remove bleeder bottle (704153) and install button

- head cap screw (402482) and stat-o-seal (S572).

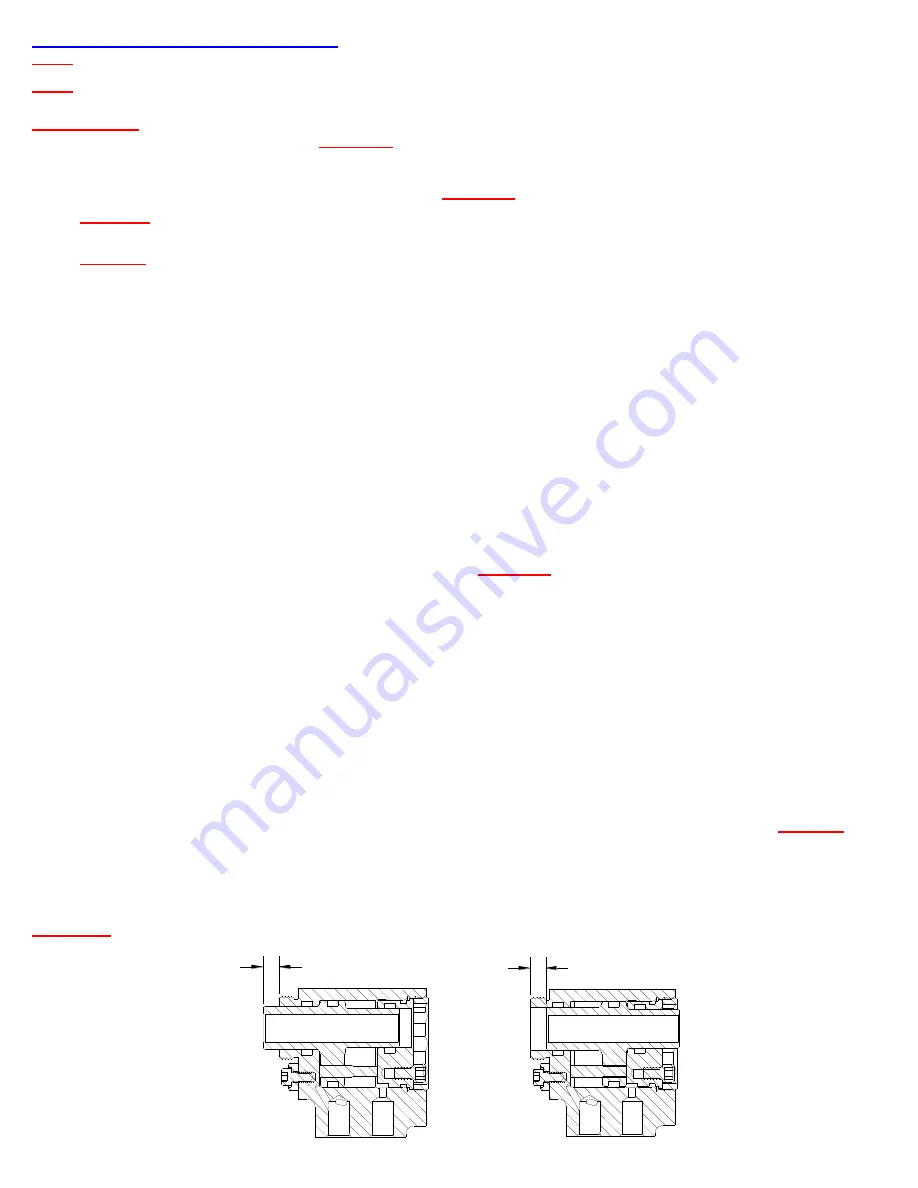

19. Connect air and cycle tool several times, check dimensions below, if dimensions do not check repeat steps 12-19.

WARNING:

Failure to follow these instructions carefully could result in severe personal injury.

.250

.250

FILLING & BLEEDING PROCEDURE:

NOTE:

704153 and 745163 Bleeder bottles are required.

NOTE

:

To replace a small amount of oil follow bleeding steps 11-19.

IMPORTANT:

Be sure to use thread sealant on all hydraulic fittings, Loctite® 30534 or similar Teflon® infused pipe

dope is recommended.

CAUTION:

Teflon tape is an excellent thread sealer, however, if it is not

properly applied, pieces of Teflon may enter the hydraulic system and cause malfunction or damage.

Use 1 1/2 wraps of tape on each thread. Cut off all loose tape ends. Tighten until fitting feels snug and

then go 1/2 to a full turn past that point.

CAUTION:

Over tightening can easily distort the threads.