10

REV 5/22

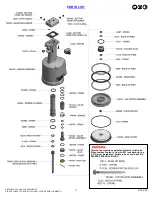

GB745/206

-

500 S/N:1329 AND ABOVE

PLEASE CONTACT GAGE BILT FOR ALL OTHER SERIAL NUMBERS.

TORQUE SPECIFICATIONS

Button Head Cap Screws (A

-

928) = 40 inch lbs. (4.52 Nm).

Packing Plug (744118) = 45 foot lbs. (61 Nm).

Flexlock Nut (400559) = 40 inch lbs. (4.52 Nm).

Button Head Cap Screws (402482) = 35

-

40 inch lbs. (3.95

-

4.52 Nm)

(Do NOT over

-

tighten).

DAILY MAINTENANCE

WARNING

:

Tool must be maintained in a safe working condition at all times and examined on a daily basis for damage or

wear. Any repair must be done by qualified personnel trained on Gage Bilt procedures.

WARNING

:

Excessive contact with hydraulic oil and lubricants must be avoided.

WARNING:

Maintenance personnel

MUST

read and understand all warnings and cautions.

WARNING

:

Disconnect tool from its power source before performing maintenance, cleaning or when replacing worn or

damaged components. Severe personal injury may occur if power source is not disconnected.

WARNING:

Read material Safety Data Sheet documents for all applicable materials

Note:

•

Dispose of hydraulic oil in accordance with manufacture safety datasheet.

•

All tool materials are recyclable except rubber o

’

rings, seals and wipers.

The performance of any tool depends upon good maintenance practices. Following these minimal requirements for service and care

will extend the life of your tool.

*Only use a clean dry air supply set at 90

-

100 p.s.i. (6.2

-

6.9 bar) Max. equipped with a filter

-

regulator to prevent wear.

*Proper care by operator is necessary in maintaining full productivity and reducing downtime. Read all applicable tool manuals and

nose assembly data sheets prior to operating tools.

*Check tool and nose assembly for damage. (Replace/Repair if necessary). See overhaul (pgs. 14

-

15) for tool repair.

* Inspect hoses and couplings for wear, damage and leaks. (Replace/Repair if necessary).

* Verify that hydraulic hose fittings and couplings, air and electrical connections are secure. Tighten, Replace or Repair if necessary

(

See hydraulic thread preparation below).

*Keep nose assemblies, especially jaws, clean and free of chips and debris. Lube jaws and collet surfaces that jaws ride on with

light machine oil on a daily basis.

*All Screwed End Caps, Base Covers, Air Fittings, Air Actuators, Screws and Nose Assemblies are to be examined at the end of

each working shift to check that they are secure.

*Check tool, all hoses and all couplings daily for damage or air/hydraulic leaks. Tighten or replace (if necessary).

*A complete overhaul can be achieved by the use of Service Kit (745214) which contains a complete set of o'rings, back

-

up rings,

screws, washers and gasket.

* For a complete overhaul, service tool kit (GB745/204TK

-

1) is recommended (see overhaul pg. 14

-

15).

WEEKLY MAINTENANCE

•

Keep the hydraulic system full (only use Dexron® III or equivalent) and free of air by using the air bleeder assembly (704153) on a

weekly basis. or as needed. (See Filling and Bleeding procedure pgs. 11

-

12).

SEE TROUBLESHOOTING (PG. 13) AND OVERHAUL (PGS. 14

-

15) FOR FURTHER GUIDANCE.

HYDRAULIC THREAD PREPARATION

IMPORTANT:

Be sure to use thread sealant on all hydraulic fittings, Loctite® 545 or equivalent or a non

-

hardening Teflon®

thread compound such as Slic

-

tite®. Tighten until fitting feels snug and then continue to tighten 1/2 to 1 full turn.

CAUTION:

Over

tightening can easily distort the threads. DO NOT USE TEFLON® TAPE.

CAUTION:

Teflon® tape is an excellent thread sealer, however,

if it is not properly applied, pieces of Teflon® may enter the hydraulic system and cause malfunction or damage.