13

REV. 6/22

GB745SH

-

5 INSTALLATION TOOL S/N: 1046 AND ABOVE

PLEASE CONTACT GAGE BILT FOR ALL OTHER SERIAL NUMBERS.

STROKE LIMITER INSTALLATION INSTRUCTIONS

WARNING:

Stroke limiters are designed for the protection of the operator and equipment. Failure to operate tool without the

proper stroke limiter will result in damage to the nose assembly or tool and may result in personal injury.

WARNING:

Do not cycle tool without air bleeder assembly (704153), or the screw and stat

-

o

-

seal, installed in tool head. Severe

personal injury could result.

CAUTION:

Before filling handle assembly (744129), air piston assembly (744121) must be all the way down.

CAUTION:

When forcing piston rod assembly (745344) downward, with head cylinder (745366) removed, hydraulic oil will eject forcibly

from handle assembly (745129).

CAUTION:

When bleeding tool, ensure tubing is free from kinks or other obstructions.

CAUTION:

Use CAUTION when removing screws, air bleeder assembly (704153) and fill bottle (745263). Hydraulic oil may be under pressure.

Note:

•

If you are unsure your nose assembly requires a stroke limiter, contact Gage Bilt for assistance.

1. Cycle tool to the rear position and disconnect air.

2. Remove end cap (745616).

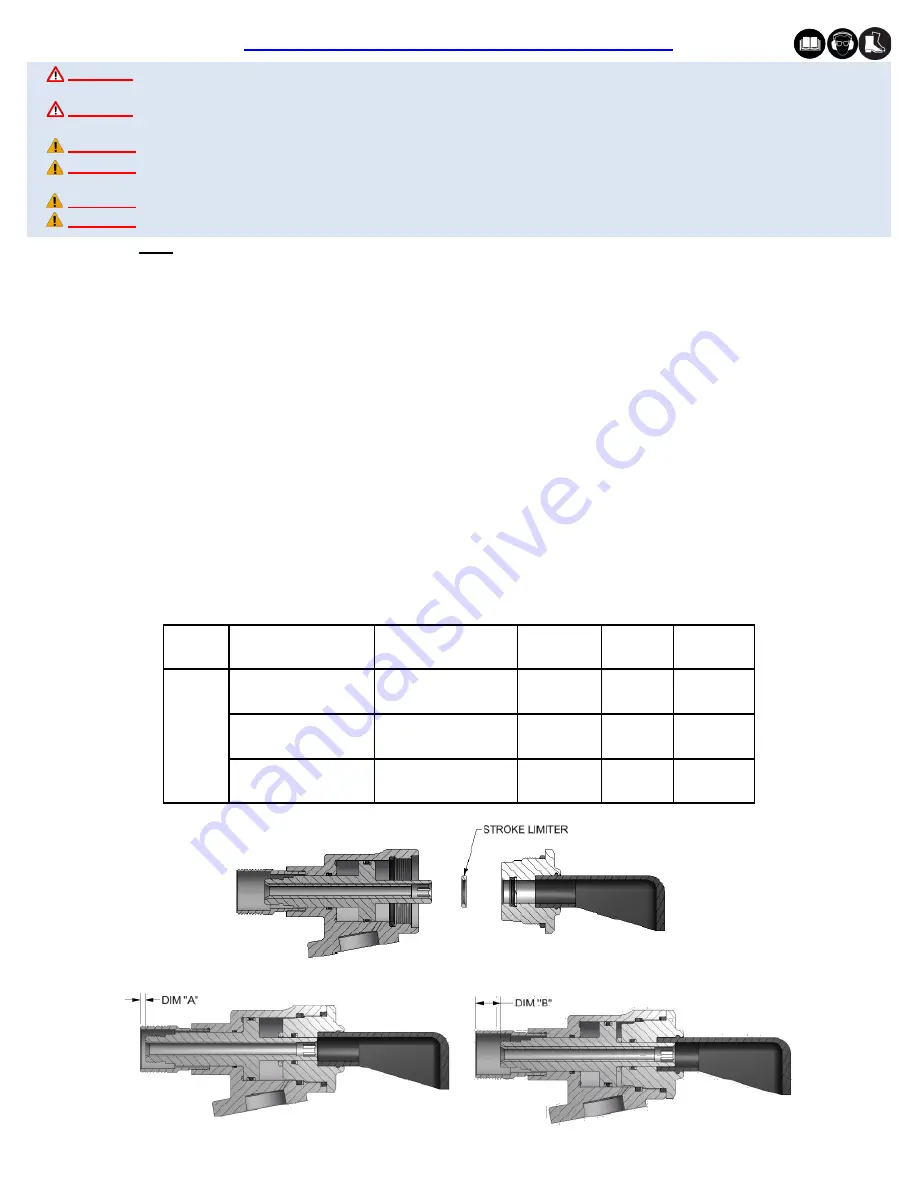

3. Install stroke limiter over rear of piston assembly (745310). See nose assembly selection chart to select stroke limiter.

4. Remove button head cap screw (402482) and stat

-

o

-

seal (S572) from front bleeder hole marked

“1”.

5. Install end cap (745616) and torque to 45 foot lbs. (61Nm). Oil will drain from front bleeder hole marked

“1”

during installation.

6. Attach button head cap screw (402482) and stat

-

o

-

seal (S572) to front bleeder hole marked

“1”

and torque to 35

-

40 inch lbs. (3.95

-

4.52 Nm).

Do not over tighten.

7.

Connect tool to air and using a pair of dial calipers, check for full stroke using instructions a thru c below. (See stroke limiter chart below).

a. With actuator lever assembly (704343) released, check dimension

“

A

”.

b. While holding actuator lever assembly (704343) check dimension

“

B

”.

c. Subtract dimension

“

A

”

from dimension

“

B

”.

If stroke is not consistent within 1/64 (.396 mm) (see stroke limiter chart below), DISCONNECT AIR SUPPLY, remove button head cap

screw (402482) and stat

-

o

-

seal (S572) from right hole (stamped #1) and attach air bleeder assembly (704153).

Then remove button head cap screw (402482) and stat

-

o

-

seal (S572) from left hole (stamped #2).

8. Insert a

3/8”

Allan wrench in back of piston (745310) and manually push the piston (745310) full forward until dimension

“

A

”

checks correct.

Replace stat

-

o

-

seal (S572) and button head cap screw (402482) into hole (stamped #2) and torque to 35

-

40 inch lbs. (3.95

-

4.52 Nm).

Continue bleeding tool by following steps 1

-

12 from bleeding procedure (See pg. 12).

TOOL

STROKE LIMITER

STROKE LIMITER

THICKNESS

STROKE

"A"

"B"

GB745

NONE

NA

.620"

15.75mm

.147"

3.73mm

.767"

19.48mm

745158

.245 (6.22mm)

.375"

9.53mm

.147"

3.73mm

.522"

13.26mm

745160

.120 (2.54mm)

.500"

12.7mm

.147"

3.73mm

.647"

16.43mm

Images may not

reflect actual tool.