Replacing the main nozzle 2

Proceed as follows:

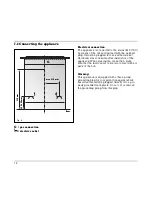

– The main nozzle 2 is visible after detaching the

burner cover (see Fig. 11). It is unscrewed with a

special screw key.

– Unscrew the nozzle and insert the new nozzle as

specified in the main nozzle table. The nozzle

must be screwed in fully and firmly (torque

1.5 Nm) (metallic seal).

– Please do not forget to stick the new adhesive

label included with the nozzle set over the old

adhesive label on the gas connection, thus

documenting the changeover to a different gas

type.

Checking functions

The flames are adjusted correctly if no yellow tips

are visible and if they do not go out when switching

over swiftly from the high to the low setting.

Adjusting the primary air

The primary air setting for different gases is only

defined by the diverse nozzle shapes and therefore

does not require adjustment.

17

Fig. 11

See table on Page 12 for details of nozzle

settings.