Fitting the appliance

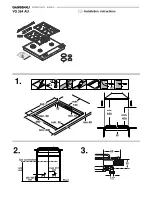

1.

Mark the centre of the recess exactly. Fit the short mounting rail

to the front of the recess and the long mounting rail to the rear

of the recess. Make sure the lugs of the mounting rails lie on

the worktop. The centre marking on the mounting rails must be

precisely flush with the centre marking of the recess.

Note:

when fitting the appliance in a stone worktop glue on the

mounting rails with a temperature-resistant two-component

adhesive (metal on stone).

2.

For combination with the appliance cover VD 201: secure the

appliance cover on the appliance before installation (refer to

the installation manual of VD 201).

3.

Lower the appliance into the cut-out. The snap-in pins on the

appliance must lie exactly on the catch springs. Firmly press

the appliance into the cut-out.

The pins on the appliance must

snap into the catch springs.

Removing the appliance

Disconnect the appliance from the power and the gas supply.

Push out the appliance from below.

Caution!

Risk of damage! Do not lever out the appliance from above.

Gas connection

The supply connection point shall be accessible with the

appliance installed.

Using the R½'' (for appliance side) connection elbow provided,

connect the appliance with the associated gasket to a fixed

connection pipe. For natural gas the regulator must be

connected.

If using a flexible connection

This appliance is approved for connection by a CLASS B hose.

Connection is in compliance with AS/NZS 5601.1

There are two ways to carry out the connection to the main gas

line:

■

A: The hotplate can be connected with rigid pipe.

■

B: Flexible Hose: If installing with a hose assembly, install with

a hose assembly that complies with AS/NZS 1869 (AGA

Approved), 10 mm ID, class Bor D, no more than 1.2 m long

and in accordance with AS/NZS 5601.1. Ensure that the hose

does not contact the hot surfaces of the hotplate, oven,

dishwasher or any other appliance that may be installed

underneath or next to the hotplate. The hose should not be

subjected to abrasion, kinking or permanent deformation and

should be inspected along its entire length with the cooktop in

the installed position. Unions compatible with the hose fittings

must be used and all connections tested for gas leaks.

Before leaving - check all connections for gas leaks with soap

and water. DO NOT use a naked flame for detecting leaks.

Ignite all burners both individually and concurrently to ensure

correct operation of gas valves, burners and ignition. Turn gas

taps to low position and observe stability of the flame for each

burner individually and all together.

Adhere the duplicate data plate to an accessible location near

to the cook top. When satisfied with the cook top, please

instruct the user on the correct method of operation. In case the

appliance fails to operate correctly after all checks have been

carried out, refer to the authorised service provider in your area.

Electrical connection

Check that the appliance has the same voltage and frequency

as the electrical installation system.

The hob is delivered with a mains cable and 3 pin moulded

plug.

Only connect the appliance to sockets which have been fitted

and earthed according to regulations.

The appliance corresponds to type Y: the mains connection

cable must only be replaced by the after-sales service. Check

the cable type and minimum cross section.

Technical data / nozzle table

Total connected load electric 0.8 VA

Nozzle table

Conversion to another type of gas

This gas hob corresponds to the categories specified on the

rating plate. It is possible to convert the appliance to any of the

gases listed on the plate by changing the nozzles. The

modification kit can be ordered via our after-sales service.

Depending on the model the parts required may beincluded in

the scope of delivery.

The conversion must be carried out by an authorised person.

Before carrying out the conversion, turn off the electricity and

gas supply.

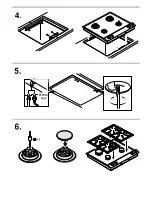

Changing the low burn nozzle – fig. 5:

1.

Remove the cover from the underside of the appliance under

the gas valves. The low burn nozzle is located in the gas valve

and is screwed in from below.

2.

Unscrew the nozzle and insert the new nozzle as specified in

the low-setting nozzle table. The nozzle must be screwed in

fully.

3.

Fit the cover cap again.

Changing the full burn nozzle – fig. 6:

1.

Remove the pan supports and burner lids.

2.

Change the nozzles. Care should be taken to ensure that the

nozzles do not break off when screwed in or out.

3.

Screw the new nozzles in as far as they will go to achieve a

good seal.

4.

Replace the pan supports and burner lids, checking that they

are correctly positioned.

If it should be necessary to correct the low-setting nozzle as the

result of deviating gas types and pressure, the flow rate can be

increased by turning to the left.

These burners do not require the primary air to be adjusted.

Checking functions after the conversion:

The flames are adjusted correctly if no yellow tips are visible

and if they do not go out when switching over swiftly from the

high to the low setting.

Note:

stick the adhesive label included with the nozzle set over

the rating plate of the appliance to document the changeover to

a different gas type.

Gas

Natural Gas

Propane Gas

Pressure

1.0 kPa

2.75 kPa

A-burner full burn

118

74

A-burner low burn

58

36

B-burner full burn

148

87

B-burner low burn

68

42

Total connected load 34.0 MJ (9.4 kW)

31.4 MJ (8.7 kW)

Total consumption

0.9 m³/h

680 g/h

Summary of Contents for VG 232 234 AU

Page 2: ...PD...