Boiling point adjustment (calibration)

Switching on

Switching off

The boiling point must be adjusted (calibration)

before first-time operation

and whenever you

change location.

Proceed as follows:

– Fill the steam cooker's cooking basin with water

up to the bottom marking and fit the glass cover.

– Turn the “Temperature" control knob to the 95°C

position.

– You must carry out the following operation within

5 seconds

:

– Turn the same control knob to and fro

two times

between the steam cooking level and the 95°C

position. Then turn the control knob to the

“steam cooking level" (Fig. 5).

Note:

The

(heating) symbol flashes during

automatic boiling point adjustment. As soon as the

(heating) symbol has stopped flashing, the

boiling point adjustment has been completed and

the appliance is ready for operation.

The time needed for the boiling point adjustment

depends on the filled quantity and the water

temperature. Boiling point adjustment takes

between 3 and 7 minutes.

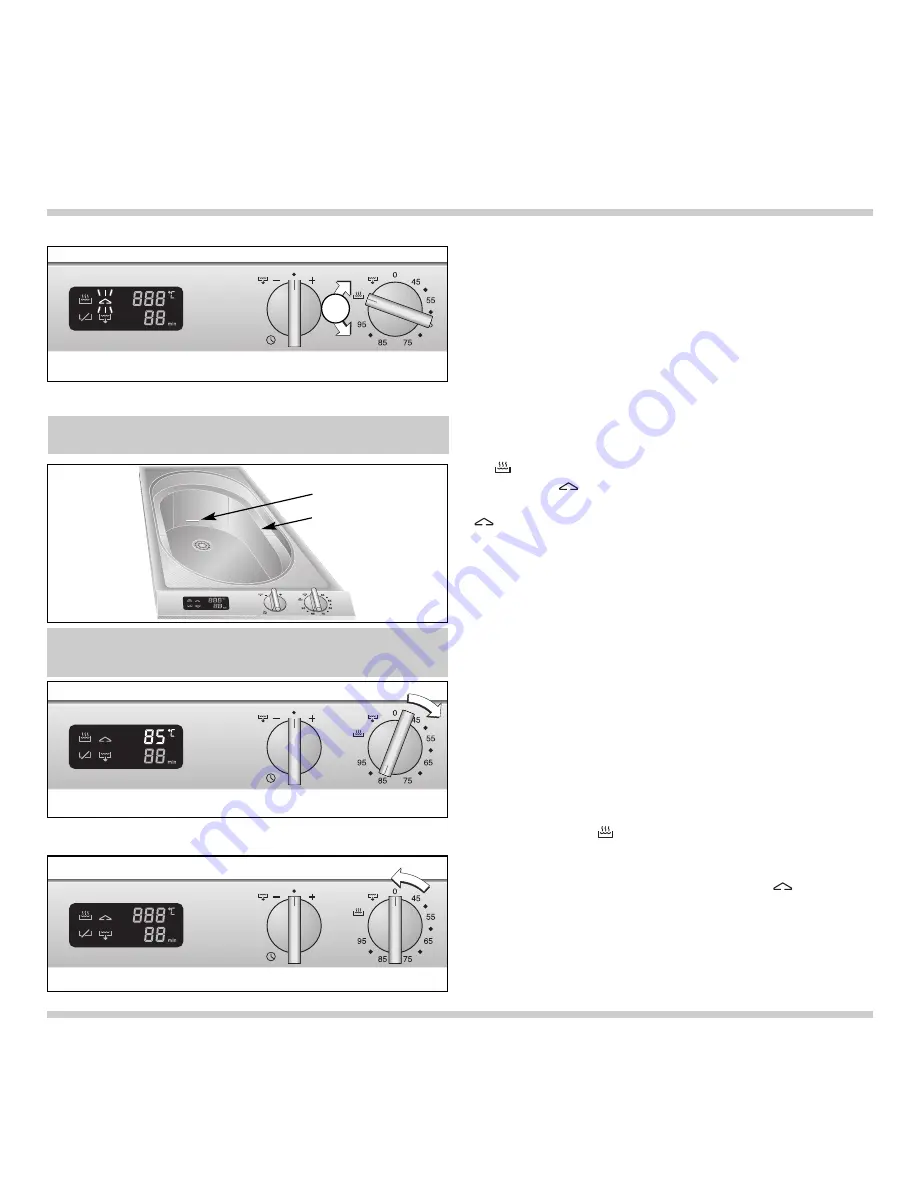

Switching on:

–

Fill

the cooking basin with water or another

cooking liquid. (Refer to the cooking table and

recipe book for quantity information.) The

cooking basin may be filled with water as

maximum up to the foaming edge and as

minimum down to the bottom marking (Fig. 6).

–

Turn

the “Temperature" knob to the

temperature you require or to the steam cooking

level (Fig. 7).

–

The symbol

(steam level) or the temperature

you have set appears on the display

(temperature range 45 - 95°C).

While the appliance is heating up, the

(Heating)

symbol will appear on the display.

Switching off:

Turn the “Temperature" knob back to position 0

(Fig. 8).

3. Operation

7

Important:

Never

operate the steam cooker

without liquid

.

Caution! The appliance heats up and gets hot!

Fig. 5

Fig. 7

Fig. 8

2x

Fig. 6

min

max