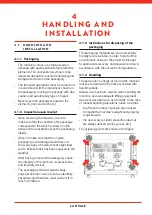

3.2 MAIN COMPONENTS

1. Main switch

2. Left steam nozzle

3. Right steam nozzle

4. Left steam dispensing lever

5. Right steam dispensing lever

6. Filter holder

7. Water pump pressure gauge

8. Adjustable support foot

9. USB ports

10. Cup warmer tray

11. Espresso dispensing units

12. Cup support tray

13. Mobile stand for short cups

14. Espresso dispenser zone LED

15. Casing LED

16. Hot water dispenser

17. Hot water dispensing buttons

18. Touch-screen display

19. Single/double short espresso dispensing

button

20. Single/double long espresso dispensing

button

21. Manual espresso dispensing start/stop

button

ENG

18

GENERAL INFORMATION

Summary of Contents for La Reale

Page 1: ...INSTALLATION AND USE ...

Page 6: ...ENG IV CONTENTS ...

Page 14: ...ENG 8 GENERAL INFORMATION ...

Page 22: ...ENG 16 GENERAL INFORMATION ...

Page 29: ...14 3 5 2 10 15 4 6 10 13 11 13 1 8 12 9 7 12 4 A 4 B ENG LA REALE GENERAL INFORMATION 23 ...

Page 80: ...ENG 74 GENERAL INFORMATION ...

Page 82: ...ENG 76 GENERAL INFORMATION ...

Page 83: ...LA REALE ELECTRIC AND HYDRAULIC DIAGRAMS 8 ...

Page 86: ...ENG 7 PURPLE 7 PURPLE 6 6 6 0 0 0 0 0 0 0 0 0 80 DIAGRAMS ...