ENGLISH

26

8

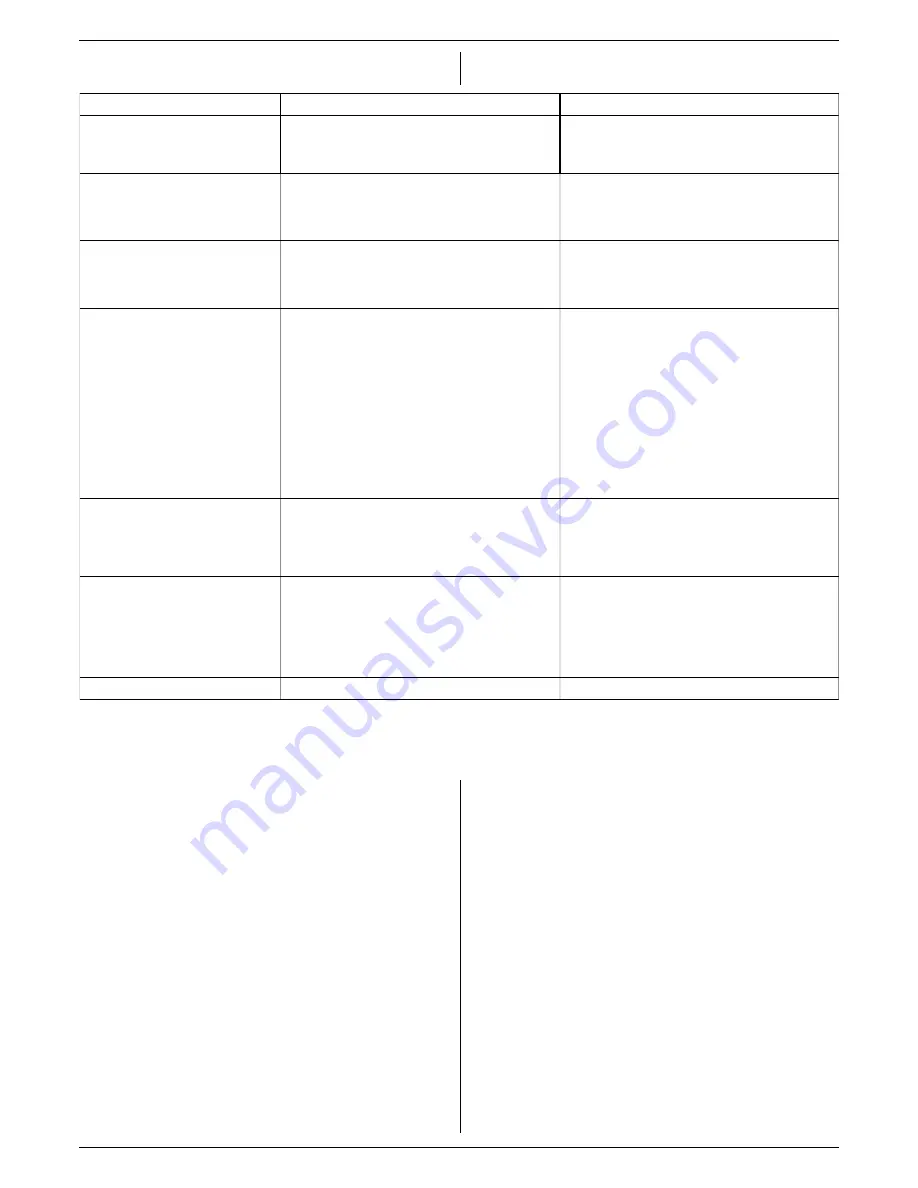

TROUBLE SHOOTING

9

MACHINE DISMANTLING

To dismantle the machine we recommend that it is dismantled

and the parts separated according to the type of materials involved

(plastic, metal, etc). The parts separated in this way are then to be

sent to the relative specialized disposal companies.

PROBLEM

CAUSE

REMEDY

Machine switch off

1. Machine switch off

1. position the machine switch to position 1

2. Cable not properly connected

2. Connect power cable

No water in boiler

1. Water tank empty

1. Fill tank

2. Tank plates not inserted

2. Insert plates into tank

3. Motor driven pump not in operation

3. contact specialized personnel

No unit delivery

1. motor driven pump out of order

1. contact specialized personnel

2. unit solenoid valve out of order

2. contact specialized personnel

3. unit switch out of order

3. contact specialized personnel

Steam fails to come out of

the nozzle

1. too much water in boiler

1. see specific problem

2. damaged resistance

2. contact specialized personnel

3. clogged sprayer element

3. clean the sprayer element

4. resistance saver engaged

4. reinsert the resistance

Too much water in the boiler

1. the motor driven pump remains

engaged

1. contact specialized personnel

2. perforated exchanger

2. contact specialized personnel

3. automatic charge solenoid valve

blocked

3. contact specialized personnel

Wet coffee dregs

1. Grinding regulated too fine

1. Adjust grinding value

2. Unit still cold

2. wait for the machine to reach the

correct temperature

3. Solenoid valve fails to discharge

3. contact specialized personnel

Coffee dispensing too slow

1. grinding element set too fine

1. Adjust the grinder

2. dirty filter-holder

2. replace the filter and undertake more

frequent filter-holder cleaning

3. clogged unit

3. contact specialized personnel

4. Solenoid valve partially clogged

4. contact specialized personnel

Coffee dispensing too fast

1. grinder is regulated too large

1. regulate the grinding

Summary of Contents for TS

Page 60: ...MARRONE BROWN ...