25

✓

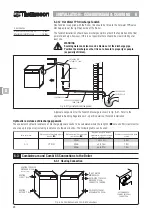

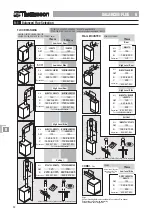

Supplied with Combistream

✓✓

Supplied with Combistream and Combi 65

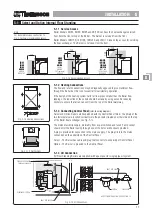

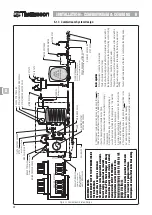

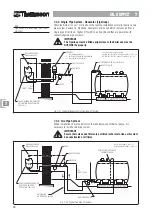

COLD

WATER

STORAGE

(Accumulator)

3

STOP COCK

DOUBLE CHECK VALVE

33

PRESSURE REGULATING VALVE

33

OUTSIDE TAP

CLEANSTREAM

3

DRINKING WATER

SERVICING VALVES

INST

INST

INST

INST

INSTALLA

ALLA

ALLA

ALLA

ALLATION - COMBISTREAM & COMBI 65 6

TION - COMBISTREAM & COMBI 65 6

TION - COMBISTREAM & COMBI 65 6

TION - COMBISTREAM & COMBI 65 6

TION - COMBISTREAM & COMBI 65 6

Before fitting the valve flush the supply pipework.

Periodically clean the filter and check or replace the cartridge with filter assembly.

WARNING

Take care not to alter the setting screw which is retained in the cap, it is

recommended to hold the spring in the cap as it is removed.

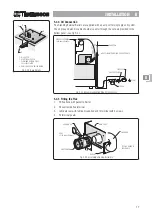

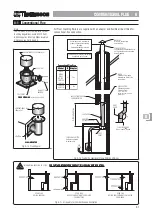

6-2.11 ‘Cleanstream’ Scale Prevention Unit

A ‘Cleanstream’ scale prevention device is supplied with the Combistream System. This

unit is effective in protecting the plumbing against both scale and corrosion.

It operates fully automatically by using the water flow to create a protective solution

which is deposited as a thin film on the inside of the pipes, cylinders and around heating

elements. The dose, which is proportional to the flow rate at approximately 5ppm, is

provided by a patented calibration system which is an integral part of the replaceable

cartridge.

The Cleanstream has a red ball that is visible through the yellow bowl of the unit, when

this ball reaches the bottom of the cartridge it indicates that the cartridge should be

replaced.

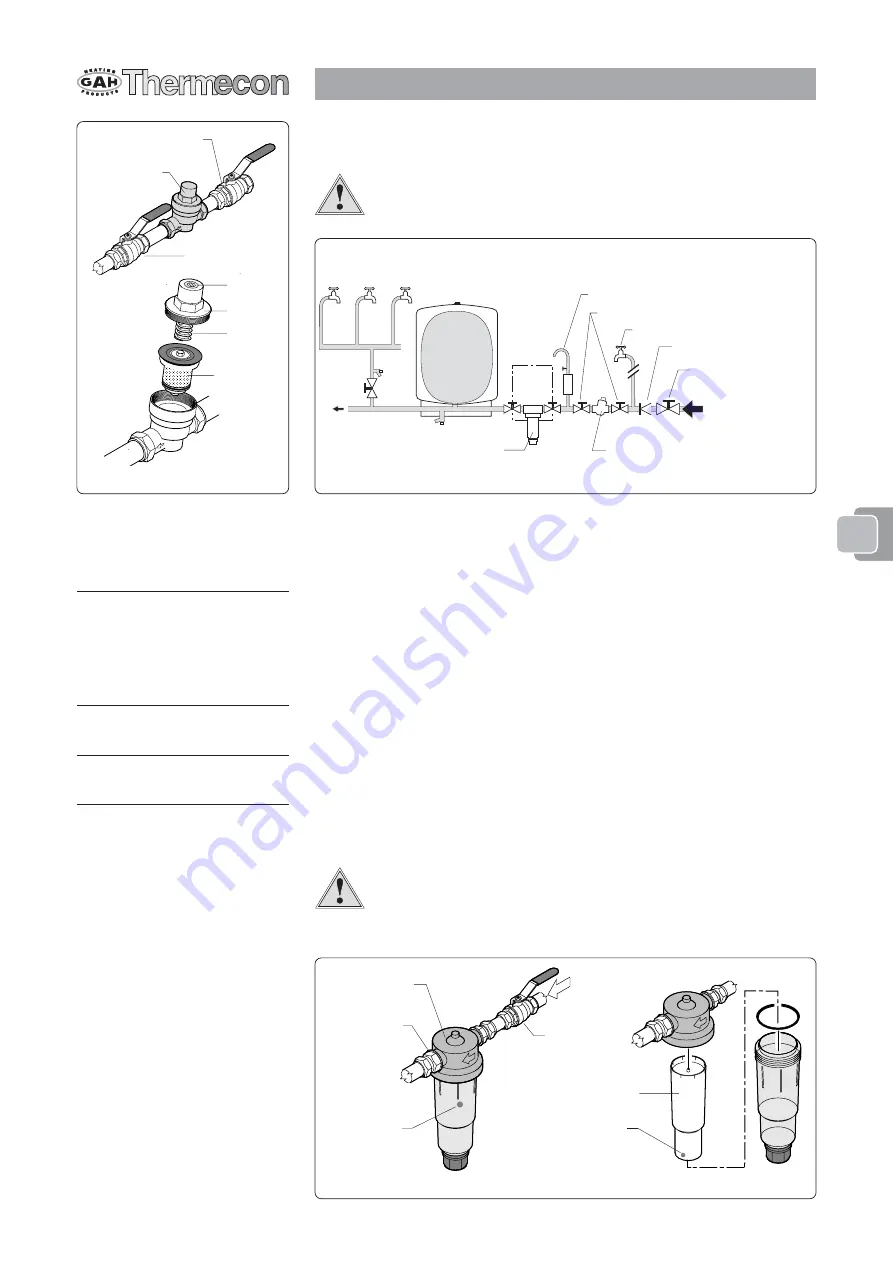

The Cleanstream unit should be fitted to the incoming main before the Accumulator and

after any drinking water outlets as shown in fig. 6-2d.

When a water softener is fitted, the Cleanstream unit should not be necessary.

To enable cartridge change, a servicing valve should be fitted to the inlet side of the unit,

a non-return valve is included in the outlet of the unit - see fig. 6-2e.

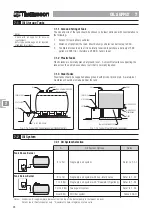

IMPORTANT

Do not overtighten fittings as this could damage the plastic body.

Fit the unit with flow in the correct direction (as arrow).

Ensure the nut at the bottom of the unit is tight.

Allow at least 30mm under the unit for cartridge replacement.

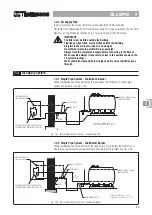

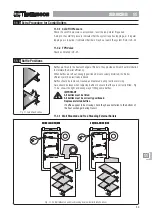

Fig. 6-2d Pressure Regulating Valve and Cleanstream Location

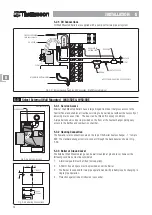

LABEL

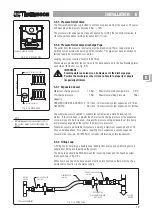

CAP

SPRING

CARTRIDGE

WITH FILTER

SERVICING VALVE

PRESSURE

REGULATING VALVE

SERVICING VALVE

Fig. 6-2c Pressure Regulating Valve

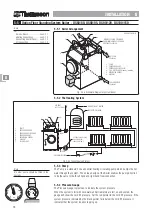

Cleanstream Specification

Normal working pressure ..... 0.5-10 Bar

Pressure tested to ....................... 25 Bar

Temperature range ..................... 1-40°C

Max flow rate ........................ 3000 ltr/hr

Pressure loss ...................... 0.2-0.7 Bar

Cartridge life whole house .......... 6 mths

Cartridge life heating system .... 12 mths

Note

Replacement cartridges are available from

builders and plumbing merchants or from

GAH.

Fig. 6-2e Cleanstream Unit

RED BALL

CARTRIDGE

RED BALL

REPLACE CARTRIDGE WHEN

RED BALL IS AT THE BOTTOM

SERVICING VALVE

CLEANSTREAM UNIT

INTERNAL

NON-RETURN VALVE

66666