Pub. 42004-455B

Model 352-101, 352-102, 352-103, & 352-104 Div. 1 SMART Hazardous Area Telephones Page 11 of 17

f:\standard ioms - current release\42004 instr. manuals\42004-455b.doc

02/13

Auxiliary Outputs

Each telephone includes two isolated solid state switches capable of switching a maximum of 48 V dc,

125 mA or 28 V

RMS

ac, 80 mA

RMS

. TB2 (OUT1) and TB5 (OUT4) on the Main PCBA provide the

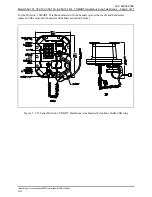

connections for the auxiliary outputs. Refer to Figure 7 for the location of TB2 and TB5.

Output 1 connects to TB2 on the Main PCBA. Refer to Figure 7. This output activates at the start of an

incoming call and will extinguish when the handset is lifted from its cradle (call answered). This output

will activate with a cadence of 2 seconds ON followed by 4 seconds OFF during this time interval.

N

OTE

:

This output is not available on models containing the Ring Relay option.

Output 4 connects to TB5 on the Main PCBA (adjacent to TB2). This output can be remotely controlled

via an appropriate DTMF command. This remote control output could be used to activate or control a

door latch, gate relay solenoid, alarm, etc. from the called party location.

Extreme Cold Temperature Operation

GAI-Tronics’ 352 Series Division 1 SMART Telephones are equipped for operation in extremely cold

temperatures ranging to

−

40º C. Operation at these temperatures requires 5 V dc to be supplied to the

telephone.

To connect the power, remove the jumper from header P17 pins 3 and 4 and plug it into the adjacent J18

header. Refer to Figure 7 for connector locations.

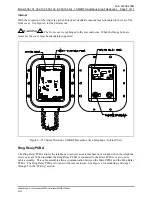

Attach the Front Cover

After all adjustments have been completed, inspect and clean the machined flange joint surfaces of both

the cover and box. Surfaces must be smooth, free of nicks, scratches, dirt or any foreign particle build-up

that would prevent a proper seal. Surfaces must seat fully against each other to provide a proper

explosion-proof joint. Clean surfaces by wiping with a clean lint-free cloth.

Apply a light coat of Killark “LUBG” lubricant to flange surfaces and close the cover. Install and tighten

all cover bolts to 30 ft-lbs. Make certain no cover bolts are omitted. Use only those bolts supplied with

the enclosure.

N

OTE

:

Refer to the Killark Installation, Operation, and Maintenance Data Sheet enclosed with the unit

for additional information.