O

FF

ON

L1

L2

70

63

76

61

1

62

42

87

88

89

82

83

84

78

79

80

GS

1

L

6

12

120

5

12

31

1.2

0.6

2

1.6

8

5

6

15

2

0.6

3

C/P

UV

L

C/P

4

14

120

5

12

45

2

1.4

0.6

2.0

10

5

9

10

2

3

0.6

S/O

W

10

2.5

12

9

9

15

R

C/P

4

12

80

5

45

12

2

S/O

2.0

0.6

1.4

20

2

5

15

2

2

0.6

S/O

L

R

4

12

2

4

80

3

12

45

1.2

C/P

0.2

2

0.6

10

4

5

15

2

0.2

2

22

C/P

G

EARED

NC

NO

COM

NC

NO

COM

C

O

CLOSE

N

NUDG.

J4

C

N

OR

J7

O

PEN

V+

LC

0V

V+

SE

0V

AUX.

BUZZER

3

1

DOL

A

UX

A

UX

3

2

AUX

NARROW

2

BLU

4

DCL

DP

M

3

GRN

YEL

ORG

()

0V

3

NC

2

B

RN

NO

HEAVY

GRN

YEL

ORG

()

0V

AU

X2

HEAVY

51

EARTH GROUND

69

86

85

81

GATE

SWITCH

2

95

7

99

C/P

4

25

243

30

21

7

S/O

6

95

99

19

30

173

5

2

1

5

98

6

99

20

270

30

2:

P

N

P

1

1:

N

O

1

90

3

99

6

G

EARED

25

100

30

DOL

CLOSE

NUDG.

MA

N.

SE

LC

SPARE

(

DOL

1

AUX

NARROW

2

DCL

4

COM

ORG

NARROW

COM

6-CONDUCTOR CABLE FOR ENCODER

6-CONDUCTOR CABLE FOR ENCODER

REV.

DESCRIPTIO

115

115

VAC

TOGGLE SWITCHES FOR

MANUAL OPERATION.

NARROWER

DOOR

LC

SE

LC

SE

ELEVATOR CONTROLLER MUST

PROVIDE COMMAND SIGNALS TO HEAVY AND/OR NARROW INPUT(S)

TO USE HEAVIER DOOR AND/OR NARROWER DOOR FUNCTION(S).

6-CONDUCTOR CABLE FOR ENCODER

DATE

Doc. No: 2500-2001-S

-1

N.C. CONTACT OPENS WHEN DOOR REACHES THE FINAL OPEN LIMIT.

DOL RELAY IS CONTROLLED BY DOL CAM FOR HARMONIC MODEL.

OR, BY DOL HALL-EFFECT SENSOR FOR LINEAR MODEL .

6-CONDUCTOR CABLE FOR ENCODER

CAN

NODE

ID

BUZZER

DEL

A

Y

TI

M

E

OVERL

O

AD

BUZ

ZER

M

O

DE

CARRIER

FREQ.

SCAN

FREQ.

LEARNING

FR

EQ.

EDG

ES

DEL

AY

TIM

E

L=

L

EF

T R

=RI

G

H

T

SEL

ECTI

O

N

O

F THE

COMMON

HAND

OF

T

H

E

DOOR

ACCEL.

TIME

DECEL.

TIME

OPEN

TO

RQUE

SL

OW

SPD

(SSO)

CLUT

CH

ENG.

DIST

.

HIGH

SPD

(HSO)

HOLDING

TO

RQUE

HOL

D

ING

SPEED

S

TA

LL

R

E

V

. F

O

R

C

E

DECEL.

TIME

FINAL

SPD

(F

SC)

FSC

BEGINS

NUDGING

SPD

HOL

D

ING

SPEED

HOLDING

TO

RQUE

HOLDING

BEGINS

CLOSING

GS

246

7-8

0-65535

0-1

FR

ONT

DOOR

=

7

0:

DISABL

E

207

204

0-1

0-1

0-1

0: M

AIN

TA

IN

0:

PERCENT

198

217

0-180

0-6

205

0-2

0:

DISABL

E

0-400

0-15

197

0-400

0-180

Pr

.#

HARM

O

N

IC

1-2

R

R

A

N

G

E

0-360

0-360

6

12

0-400

80

0-400

0-100

3

12

0-400

45

0-4.5

2.0

C/P

0-3

0-400

0.6

2

148

146

0-4.5

0-360

HARM

O

N

IC

1.4

15

142

143

0-400

0-100

3

5

144

0-400

10

138

137

0-400

0-3

2

0.6

139

0-100

2

HARM

O

N

IC

C/P

Pr

.#

R

A

N

G

E

6-CO

NDUCTO

R

CABLE FO

R ENCO

DER

E

NCODE

R

500-305

COM

1:

ENABL

E

1:

USE

DOL

1:

PUL

SES

2:

P

U

LS

E

LINEAR

C/P

G

EARED

100

5

12

50

1.2

S/O

0.2

2

LINEAR

0.9

4

5

10

15

0.2

LINEAR

S/O

(SEE N

O

TE 1)

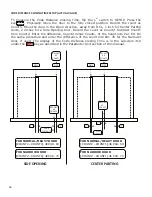

NC

NO

COM

NC

METHOD 1

NO

COM

OPEN

CL

OS

E

NUDG.

O

PEN

METHOD 2

O

INP

UT

S

IG

NA

LS

U5

NP

N

P

NP

D

PPC

0001N

ENABLE IC

(SEE N

O

TE 2)

(O

PTIO

NAL)

DE

FA

ULT B

A

U

DRA

TE

O

F P

A

R

. 247 = 115.2

KBPS

SET PAR

. 2

46

=

8

FOR RE

A

R

DOOR

SET PAR

. 2

46

=

7

FO

R

F

R

O

N

T D

O

O

R

SET PAR

. 1

1 =

5

TO

U

SE C

AN

BU

S

LIN

EAR

GEAR

ED

M

O

D

EL

:

P

A

R

. 42 = 1 F

O

R RH/LH/CP

NA

RRO

W

CL

OS

E

RUN

6-CO

NDUCTO

R

CABLE FO

R ENCO

DER

SPAR

E

14-CO

NDUCTO

R

RIBBO

N CABLE

906-

3030

906-

3013

E

CI

P

/N

INDICATO

R

CANH

INDICATO

R

10-CO

NDUCTO

R

RIBBO

N CABLE

DOL

10-CO

NDUCTO

R

RIBBO

N CABLE

NC

NO

HEAVY

LED

BLU

1

BLU

1

B

RN

RE

D

V+

V+

MF

G.

TX

(CN5

)

3

DPM

DCL

SET PAR. 199=

0

TO

ENABLE AUX

25

00

-1

00

1

SI

GN

AL

S TR

AN

SFER

BOAR

D

6-CO

NDUCTO

R

CABLE FO

R ENCO

DER

NC

NO

O

PT

IO

N

AL

AU

X.

COM

NONE

WH

T - WH

T

CONNE

CT

ION

BETWEEN

TX & R

X

EAR

TH

GROUND

E

A

RT

H G

RO

UND

PO

LE O

N

E

NCL

OS

URE

CONNECTION

NARROWER

DOOR

DET.

EDGES

M

O

DE

EDG

ES

HO

LD

TIM

E

C/P=

CENTER PARTING

FS

O

B

E

GINS

FIN

A

L S

P

D

(F

S

O

)

HOLDING

BEGINS

OPENIN

G

ACCEL.

TIME

HIGH

SPD

(H

SC)

CLOSE

TO

RQUE

M

A

X.

CL

OSE

SPEED

230V

A

C

1/

2 H

P

3PH

.

INDUCT

ION

MOT

O

R

G

A

TE

S

W

IT

CH

TO M

OT

OR

0-65535

202

199

206

0-1

0-2

0-180

1

1:

N

P

N

0:

DISABL

E

0:

YES

Pr

.#

145

0-100

0-400

0-100

0-360

98

3

99

6

R

A

N

G

E

141

140

136

0-400

0-400

0-60

25

270

30

DP

M

CONNE

CT

T

O

E

CI

P

A

R

A

M

E

TER

U

N

IT

2500-3051

2

95

5

99

2

20

120

30

RE

OP

E

N

DCL

INP

UT

S

IG

NA

LS

CL

OS

E

L

E

D

O

PEN

L

E

D

NUDG.

L

E

D

COM

OPEN

EN

ABL

E I

C

O

N

LY

W

O

R

K

S

W

IT

H E

CI

C

E

R

TIF

IE

D

DE

TE

CTOR

ED

GES

SW8

H

EAVY

HA

MO

NIC MO

DE

L:

P

A

R

. 42 = 2 F

O

R LH/CP

P

A

R

. 42 = 1 F

O

R RH

LINE

A

R S

TRA

IG

HT MO

DE

L:

P

A

R

. 42 = 1 F

O

R LH/CP

P

A

R

. 42 = 2 F

O

R RH

NUDG.

AU

TO

EDGES

TIMEOUT

DE

LA

Y

TIME

FROM

T

RI

GG

E

R

E

D

P

O

INT

I

S SET BY PAR

. 1

98

P

A

R

. 205 = 0 : DIS

A

B

LE

205 = 1: CO

N'

T

205 = 2: P

U

LS

E

BUZZER

VOLUME

CONTROL

AUX2

CN5

906-

3020

SHLD

CANL

BUS

TERM

INATIO

N SW

ITCH

CONNECT TO

CAN BUS

OF THE

ELEVATOR

CONTROLLER

OPTICAL CAM

BOARD

S

E

T P

A

R

.

201 = 1

S

E

T P

A

R

.

201 = 0

ED

G

ES

TIM

E

O

U

T

NARROW

LED

RE

D

W

HT

)

DPM

3

HA

LL-

E

FF

E

CT

SEN

SOR

BOAR

D

COM

INP

UT

SI

G

N

ALS

NARROW

NONE

CONNE

CT

T

O

J

7

O

N T

HE

M

A

IN B

O

A

RD

6-CO

NDUCTO

R

CABLE FO

R ENCO

DER

500VA MIN.

CONNECT TO ANY VOLTAGE

SOURCE FROM 24 TO 230

VOLTS, AC OR DC, 30mA MIN.

REMOVE THIS JUMPER IF

INPUT SIGNAL VOLTAGE

IS 60V OR LESS

REMOVE THIS JUMPER IF

INPUT SIGNAL VOLTAGE

IS 60V OR LESS

REMOVE THIS JUMPER IF

INPUT SIGNAL VOLTAGE

IS 60V OR LESS

CN4

CONNECT TO ECI CERTIFIED

INFRARED DETECTOR EDGES

2500-3056

CONNECT

TO ENCODER

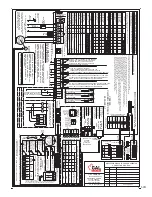

REOPEN RELAY IS ACTIVATED BY ANY ONE

OF THE FOLLOWING DETECTIONS:

1. STALL REVERSE; CONTROLLED BY PAR. 148.

2. FREQUENCY FAILURE; CONTROLLED BY PAR. 136

3. DETECTOR EDGES; CONTROLLED BY PAR. 202, SW 8, AND IC U5.

N.C. CONTACT OPENS WHEN DOOR REACHES FINAL CLOSE LIMIT.

DCL RELAY IS CONTROLLED BY DCL CAM FOR HARMONIC MODEL.

OR, BY DCL HALL-EFFECT SENSOR FOR LINEAR MODEL .

(SEE N

O

TE 1)

8

AM

P.

SLO

W

BLO

W

F

U

S

E

S

CODE

DIST

. NARROW

DOORWIDT

H

LEARNING

REAR

DOOR

= 8

1"

FO

R

S/O,

OR

2"

FO

R

C/P

FR

OM

DCL

RE-

O

PEN

REL

AY

M

O

DE

NARROWER

DOOR

DOL

0:

USE

BOTH

DOL

&

AUX

CLUT

CH

DIST

ANCE

UNIT

1: D

IS

AB

LE

W

H

EN

E

D

G

ES

RE

LAY

O

N

1:

CONT

INUOUS

STRAIG

HT

DEF

A

ULT

VALUE

Q

U

ICK

STO

P

O

N

REV.

DEFAULT VALUE

DEFAULT VALUE

STRAIG

HT

EASY SETUP PROCEDURE

WRIT

E

(DOWNL

OAD)

TO

THE

DRIVE:

Pr

ess

SET,

Pr

ess

UP

Ar

ro

w,

Pr

ess

WRIT

E.

INSTRUCTIONS FOR THE VFE2500 PARAMETER UNIT

READ

(COPY)

FROM

THE

DRIVE:

Pr

ess

SET,

Pr

ess

UP

Ar

ro

w,

Pr

ess

READ.

6-CO

NDUCTO

R

CABLE FO

R ENCO

DER

C = CLOSE O = OPEN N = NUDGING

E

D

G

E

S

T

IM

E

O

U

T

R

E

LAY

FO

R

M

U

LA

S

Y

S

TE

M

S

JA

NUS

R

ESET

LE

A

RN DO

O

R W

IDTH

FO

R HA

RMONIC MODE

L

SETU

P

25

00

-1

00

2

10-CO

NDUCTO

R

RIBBO

N CABLE

CONNE

CT

T

O

OP

TICA

L CA

M B

O

A

RD F

O

R HA

RMONIC MODE

L.

C

O

N

N

E

C

T TO

SI

G

N

AL TR

AN

SFER

BO

AR

D

FO

R

LI

N

EAR

M

O

D

E

L.

NARRO

W

ER DO

O

R

REM

O

VE THIS JUM

PER IF

INPUT SIG

N

AL VO

LTAG

E IS

60V O

R

LESS

REM

O

VE THIS JUM

PER IF

INPUT SIG

N

AL VO

LTAG

E IS

60V O

R

LESS

RX

(CN4

)

TO ELEVATOR CONTROLLER

FO

R T

HE

L

IGHT

DUT

Y

L

INE

A

R MODE

L,

TH

E

M

O

TO

R

W

IL

L B

E

2

30

V

A

C

9

1W

3P

H A

ND T

HE

E

NCODE

R IS

A

N

U

N

D

ET

AC

H

ABL

E PAR

T O

F T

H

E

MOT

O

R, P

/N:

2

50

0-

2

0

1

6

-L/R

RE

LA

Y

CONT

A

CT

S

AR

E R

A

TED

@ 10 AM

P.

250VAC

WARNING:

11

5

VAC

L

INE

G

S

&

G

S

1 A

R

E

O

N

LY C

O

N

V

E

N

IEN

C

E T

E

R

M

IN

AL

S

FO

R US

E

RS

. T

HE

Y

HA

V

E

NO

CO

NNE

CT

IO

NS

TO

V

FE

-2500 CIRCUITRY

.

CODE

DIST

. REG

/ HVY

1"

FO

R

S/O,

OR

2"

FO

R

C/P

FR

OM

DCL

: TO

L

O

WER TO

RQ

UE, INCREASE THE VAL

UE.

STRAIG

HT

CHANGE

PARM

E

TERS:

Pr

ess

SET,

En

te

r Pa

ra

m

ete

r Nu

m

be

r,

Pr

ess

READ,

En

te

r

New

Value,

Press

WRIT

E.

LE

A

RNING

DOORWIDT

H:

S

et

DOL

and

DCL

properly.

Flip

switch

to

S

E

TUP

.

Set Par. 63 = 1. F

lip switch back to RUN. F

lip next switch

to

MA

N.

Fo

llow

prompts

on

LCD

Display.

CONNECTION METHODS

D

E

LA

Y

T

IM

E

F

R

O

M

TR

IGGER

E

D

POIN

T

IS SET BY PAR

. 1

97

C

O

N

TR

O

LLER

'S R

E

LAYS M

U

ST H

AVE

TH

E SAM

E C

O

M

M

O

N

AN

D

R

ELAY C

O

IL

VO

LTAG

E MU

ST BE FR

O

M

24V -

230V

A

C OR DC.

AU

X.

R

ELAY

U

SE PAR

. 6

8 TO

SET

AU

X2

R

EL

AY.

SEE M

A

N

U

A

L FOR

DE

TA

ILS

.

TRIT

RONICS

B

U

ZZE

R IS

TRIGGE

RE

D B

Y

IN

FR

AR

ED

D

E

TEC

TOR

ED

GES.

CONNE

CT

T

O

A

DDIT

IONA

L

I/O B

O

A

RD

INF

RA

RE

D DE

TE

CT

O

R

ED

GES OU

TPU

T TYPE

SEL

EC

TOR

SWI

TC

H

.

P

A

R

. 202 =0 T

O

DI

S

A

B

LE

P

A

R

. 202 =1 F

O

R NP

N

P

A

R

. 202 =2 F

O

R P

N

P

GALVANIC

ISOLATION

CAN BUS

CARD

GALVANIC

ISOLATION

ENCODER

CARD

SET PAR

. 6

3 =

1 FOR

DO

O

R W

IDTH LE

A

RNING

VFE2500

CLOSED LOOP DRIVE

2500-3050

-1

10-CO

NDUCTO

R

RIBBO

N CABLE

FO

R L

INE

A

R

MODE

L

(OPTIONAL)

S

E

T P

A

R

. 204=0 I

F

A

UX

. CO

NT

A

CT

A

ND

RE

G

U

LA

R DO

L A

R

E

US

E

D A

S

DO

L O

F T

HE

NA

RRO

W

E

R DO

O

R.

02

VFE2500 CLOSED LOOP DOOR OPERATOR

CONNECTION DIAGRAM

DPM N.O. CONTACT MAKES 1/2 INCH BEFORE

GATE SWITCH MAKES FOR FAULT MONITOR

TO MEET ANSI A17.1 AND CAN/CSA-B44.

DPM RELAY IS CONTROLLED BY DPM CAM

OR DPM HALL EFFECT SENSOR.

ADDITIONAL I/O BOARD

2500-

3055

TO ELEVATOR CONTROLLER

E

C

I C

E

R

TIF

IE

D

IN

FR

A

R

E

D

D

E

TE

C

TO

R

E

D

G

E

S

N

O

TES:

1.

H

EAVY LI

N

ES R

EPR

ESEN

T C

O

N

N

E

C

TI

O

N

S

FR

O

M

ELEVATO

R

C

O

N

TR

O

LLER

T

O

DOOR OP

E

RA

TOR P

CB

.

2.

M

AKE SU

R

E TH

AT EN

ABLE I

C

IS I

N

SER

TED

IN

TO

SO

C

KET AS SH

O

W

N

.

ED

GES TI

M

E

OU

T R

E

LAY I

S

TR

IGGER

E

D

BY I

N

FR

AR

ED

D

E

TEC

TOR

ED

GES.

SET PAR

. 2

07

=

1

TO D

ISABL

E R

E

OPEN

R

E

LAY WH

EN

ED

GES TI

M

E

OU

T AC

TI

VATED

.

DRIVE OVERLOAD FACTORY SET AT 2.5A

IF

E

DG

E

S

T

IM

E

O

UT

O

UT

P

UT

IS

US

E

D F

O

R

N

U

D

G

IN

G

FEATU

R

E,

IT

M

U

ST BE SU

BJEC

T

TO

ELEVATO

R

FI

R

E SER

VI

C

E C

O

D

ES.

ALL EQUIPMENT MUST BE INSTALLED AND ADJUSTED

TO MEET FEDERAL, STATE / PROVINCIAL, AND LOCAL

C

O

D

E

S

. T

O

P

R

E

V

E

N

T E

LE

C

TR

IC

A

L S

H

O

C

K

, M

E

TA

LL

IC

CONDUITS, ELECTRICAL BOXES, AND MOTOR

MUST BE GROUNDED. WAIT FOR 10 MINUT

ES AFTER

R

E

M

O

V

IN

G

P

O

W

E

R

B

E

FO

R

E

S

E

R

V

IC

IN

G

.

:CONNE

CT

0

V

T

O

A

T

RUE

E

A

RT

H GROUND

6-CO

NDUCTO

R

CABLE FO

R ENCO

DER

SET PAR. 199=

0 TO

ENABE AUX

SUITABLE FOR USE ON A CIRCUIT

CAPABLE OF D

ELI

VERING NOT

MORE THAN 5000 RMS SYMMETRICAL

AMPERES,

120

VOLTS MAXIMUM,

WHEN PROT

ECTED BY

8

AMPERES,

1

20

V

R

K

5 F

U

S

E

S.

EC

I H

AS D

O

N

E

TH

IS

PR

OC

ED

U

R

E BEFOR

E SH

IPPI

N

G

VFE2

50

0 TO C

U

S

TOM

E

R

S

.

H

O

WEVER

, TH

IS

EASY SETU

P

PR

OVI

D

ES U

SER

S WI

TH

H

E

LP

FU

L STEPS,

WH

EN

N

EED

ED

.

1. TURN ON POWER AND RUN DOOR IN

M

A

NUAL

M

O

DE. IF DOOR

CL

OSES AND OPENS IN THE CORRECT DIRECTION,

GO TO 2

. I

F N

O

T,

SWAP AN

Y 2

OF M

O

TOR

WI

R

ES,

C

H

E

C

K

AGAI

N

, TH

EN

GO TO 2

.

2. ON KEYPAD, HIT VOL

T/PUL

SE KEY. RUN DOOR IN M

A

NUAL

M

O

DE AGAIN.

IN CL

OSE DIRECTION, L

C

D SHOUL

D

SH

OW "

C

LO

SE"

AN

D

PU

LSE C

O

U

N

T SH

OU

LD

D

E

C

R

EASE.

IF

N

O

T,

C

H

AN

G

E PAR

. 4

2. C

H

EC

K AGAI

N

, TH

EN

GO TO 3

.

3. U

SE TH

E PAR

AM

ETER

U

N

IT TO U

P

LO

AD

APPR

OPR

IATE

E

C

I DE

FA

UL

T FOR THE

DOOR OP

E

R

A

TOR, THE

N

GO TO 4

.

4. FLIP FIRS

T TOGGLE SWITCH TO SETUP

. SET

PAR. 63 = 1, FLIP

TOGGLE SWITCH

TO RUN, RUN THE DOOR IN M

A

NUAL M

O

DE

.

FOL

LOW INSTRUCTION ON L

CD DISPL

AY TO COM

P

LE

TE D

OOR WIDTH L

EARNING PROCESS. L

EARN-DOOR-W

IDTH L

E

D WIL

L

FL

ASH AND TURN OFF WHEN

PROCESS IS

COM

P

LE

TE

D.

L

CD DISPL

AY WIL

L SHOW "L

EARNING COM

P

LE

TE

D."

P

A

R

A

M

E

TE

R

63 W

ILL RE

TURN TO

ZE

RO

B

Y

ITS

E

LF.

5. FL

IP FIR

ST TOGGL

E SWITC

H

TO SETU

P

. SET PAR

. 1

1 =

1

FOR

R

E

GU

LA

R

OPER

ATION

.

S

E

T P

A

R

. 11 = 5 FOR CA

N B

U

S

OP

E

R

A

TION. FLIP

TOGGLE

S

W

ITCH TO RUN.

6. TE

S

T DO

O

R IN MA

NUA

L MO

DE

, A

ND TE

S

T DO

O

R IN A

UTO

MA

TIC MO

DE

. DO

NE

!

*277$5'2

&57

.

MISSISSAUGA, ONTARIO

L

7

2

$

2 CANADA

TEL: (905) 624-6565

FAX: (905) 624-4262

GAL CANADA

51B

Summary of Contents for MOVFE 2500

Page 1: ...2500 3069 1 888 425 2262 2500 3069 ELECTRICAL...

Page 2: ...Rev 1 10 20 I...

Page 24: ...19 6 DEFAULT PARAMETERS 19...

Page 26: ...21 FAULTS AN EXAMPLE OF FAULTS DISPLAY COUNTERS 21...

Page 27: ...22 USER LIST 22...

Page 28: ...23 23...

Page 29: ...24 24...

Page 30: ...25 25...

Page 31: ...26 MAXIMUM CLOSE SPEED AND FORCE 26...

Page 32: ...27 ECI DEFAULT PARAMETER SETS 27...

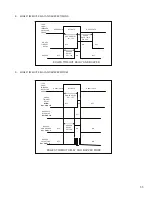

Page 34: ...29 SPEED PROFILES OF THE VFE2500 FOR NORMAL DOOR 29...

Page 35: ...30 SPEED PROFILES OF THE MOVFE2500 FOR HEAVY DOOR 30...

Page 36: ...31 SPEED PROFILES OF THE MOVFE2500 FOR NARROW DOOR 31...

Page 91: ...Rev 10 20 85...

Page 92: ......