GALA ELECTRONICS 300 T

GALA ELECTRONICS 300 T

GALA ELECTRONICS 300 T

GALA ELECTRONICS 300 T

E

E

E

E

GB

GB

GB

GB

0

24

1 INTRODUCTION

IMPORTANT!

This handbook must be consigned to the user prior to

installation and commissioning of the unit.

Read the "General prescriptions for use" handbook supplied

separately from this handbook before installing and

commissioning the unit.

The meaning of the symbols in this manual and the associated

precautionary information are given in the "General

prescriptions for use”.

If the "General prescriptions for use" are not present, it is

mandatory to request a replacement copy from the

manufacturer or from your dealer.

Retain these documents for future consultation.

KEY

This symbol identifies an action that occurs automatically as

a result of a previous action.

This symbol identifies additional information or a reference to

a different section of the manual containing the associated

information.

§

This symbol identifies a reference to a chapter of the manual.

This symbol accompanies important information concerning

the execution of the relevant operations.

300T is an inverter-based welding power source complete with all the

functions required for DC TIG and MMA welding with excellent arc

characteristics.

The solidity of the components of this unit makes it a reliable working

companion for workshop and outdoor applications.

This unit is ideal for maintenance, food industry, hydraulics, oil

pipelines and chemical plants.

The parameters preset in the DC TIG pulsed synergic curve simplify

welding by regulation exclusively of the current.

The current is adjustable also from the Up-Down torch.

The simply and intuitive interface allows high precision adjustments

with 50 storable programs.

The wide range of adjustable pulsed frequency in combination with

the complementary parameters (base current and duty cycle) makes it

possible to weld in slow and fast pulsed mode.

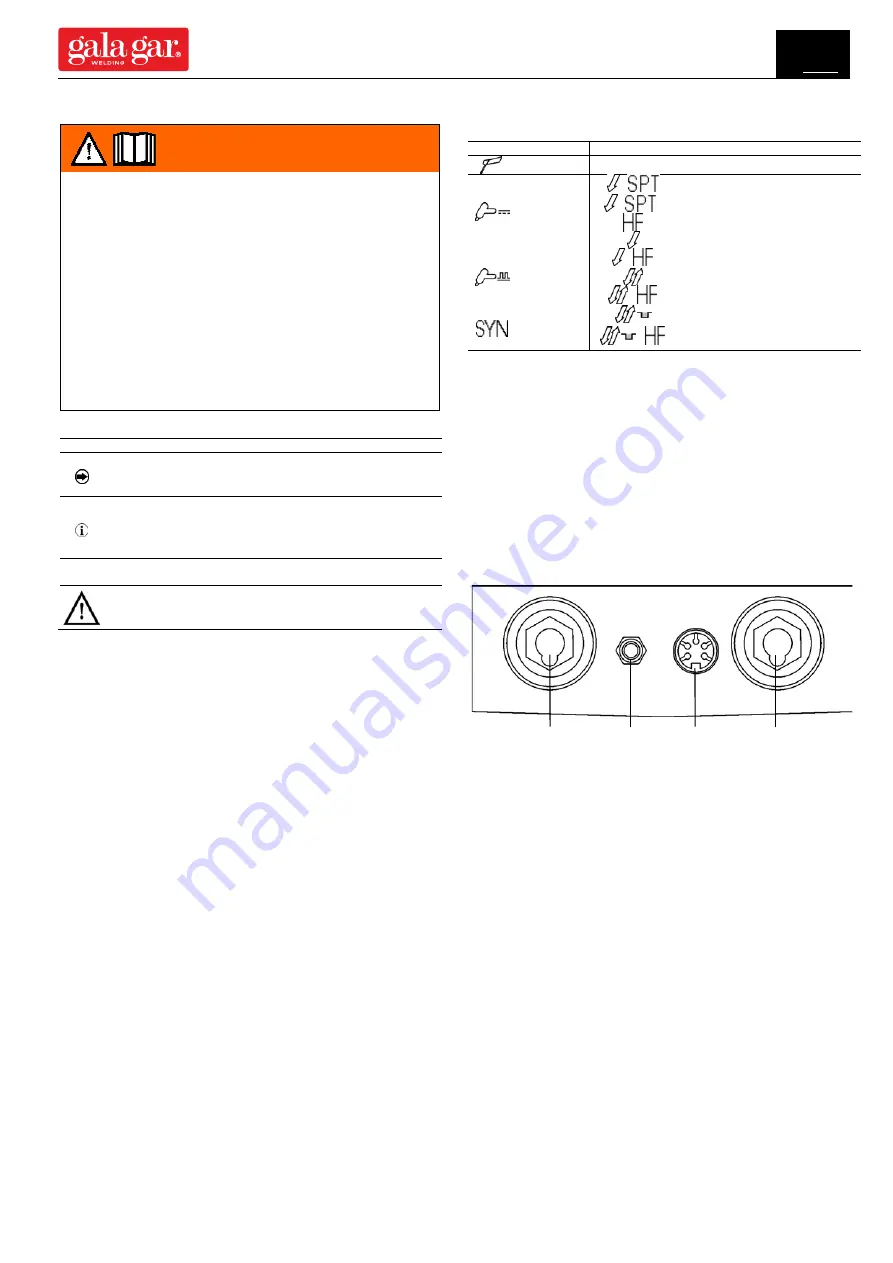

The welding modes and procedures available are those indicated in

the table.

MODE

PROCEDURE

MMA

TIG

CONTINUOUS

+

2T SPOT

+

+

2T SPOT + HF

2 STEP LIFT-ARC (2T)

TIG PULSED

+

2 STEP + HF (2T HF)

4 STEP LIFT-ARC (4T)

+

4 STEP + HF (4T HF)

SYNERGIC

TIG

4 STEP BI-LEVEL (4T B-LEVEL)

+

4 STEP BI-LEVEL + HF (4T B-LEVEL

HF)

Accessories that can be connected to the unit:

−

manual remote controller for remote adjustment of the welding

current.

−

foot-pedal remote controller for TIG torch arc striking and remote

adjustment of welding current.

−

UP/DOWN torch or torch with potentiometer.

−

liquid cooler for TIG torches.

2

FRONT PANEL

1

4

3

2

1: Negative pole welding socket.

2: Positive pole welding socket.

3: Connector for logic signals of TIG torch.

4: Connector for gas feed hose:

power source

torch