GALA MIG (V. COMPACTA). Manuel d'Instructions

17

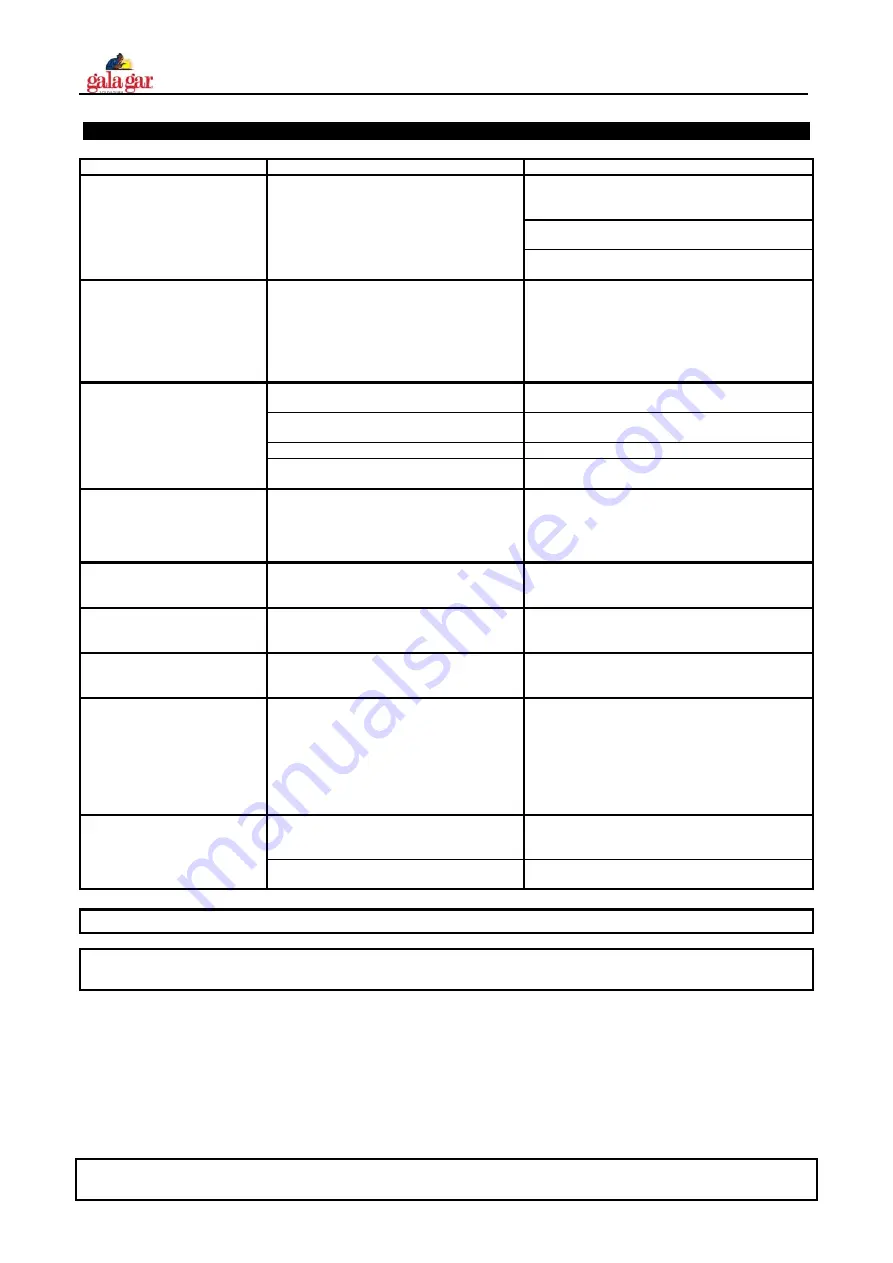

5. ANOMALIES. PROBABLE CAUSES. POSSIBLE SOLUTIONS.

SYMPTOM. ANOMALY.

PROBABLE CAUSE.

POSSIBLE SOLUTION.

1. Make sure there is voltage at the entry to the

machine, if not the tapping must be changed. It is

advisable to see if any magnetothermal has "blown".

2. Check that fuse (E) of the power source is not

open.

GENERAL PROBLEM

NOTHING WORKS.

The machine has no voltage in one or all its

vital elements.

3. The machine panels must be removed testing the

logical points of the electrical diagram.

LIMITER TRIPS

Magnetothermal switch has low gauge for the

case. There may be a short circuit, which is

what causes the limiter to trip.

Change the magnetothermal for another larger

gauge one. It is important for the magnetothermal

switch to have a characteristic slow type curve. It is

important for the magnetothermal switch to have a

characteristic slow type curve. In the event that the

electrical installation has limited power the welding

work must be tested at lower current levels.

Problem in internal connection.

Check that the internal electrical connections are

corrects.

The thermal protection has “blown”. Pilot F

illuminated. (GALA MIG 1810).

Wait until the machine cools down correctly. Do not

disconnect the machine.

Faulty electronic card.

Replace the electronic card.

ALTHOUGH THE MACHINE IS

CONNECTED AND WITH THE

SWITCH ON, THERE IS NO

REACTION WHEN PRESSED

Failure of the pistol switch which does not

make perfect contact.

Change the gun microswitch.

WHEN THE GUN IS PRESSED,

ALTHOUGH WIRE COMES OUT,

THE CONTACTOR DOES NOT

WORK OR/AND THERE IS NO

SHIELDING GAS.

Voltage does not reach the Contactor or/and

solenoid valve.

It must be established whether the fault comes from

the electronic board or if it is an electrical connection

fault.

Check that the contactor coils or/and solenoid valve

are not open.

WHEN THE SHIELDING GAS IS

RELEASED IT CONTINUES

FLOWING.

There is impurity in the inside chamber of the

solenoid valve which prevents the piston from

closing completely.

Dismantle and clean the electrovalve.

WHEN FINISHING WELDING

THE WIRE REMAINS STUCK TO

THE TORCH CONTACT TUBE.

The contactor has a very high opening delay.

Suitably regulate the Burn-Back potentiometer of the

electronic card.

WHEN FINISHING WELDING

THE FINAL WIRE LENGTH IS

VERY GREAT.

The contactor has a very low opening delay.

Suitably regulate the Burn-Back potentiometer of the

electronic card.

THE EQUIPMENT DOES NOT

WELD CORRECT.

"IT ADJUSTS BADLY"

Low effective welding voltage. Output wave not

correct.

Check that there is not a phase failure in the supply

power.

Check that the electrical contact elements of the

welding circuit are correct: Welding mass, rusty or

very dirty surfaces, contact nozzle with greater

diameter than the wire, etc.

Test the electrical diagram of the power source: input

and output voltages to the rectifier.

The welding wire has a mechanical resistance

at the outlet, which prevents it from having a

regular speed.

Examine the welding gun. Blow the inside (cable)

with compressed air.

THERE ARE MANY

PROJECTIONS IN THE WELDING

PROCESS

Unsuitable shielding gas.

When welding normal steels we advise the use of a

gas mixture Ar-CO2.

SPECIALIZED PERSONNEL MUST CARRY OUT ANY WORK ON THE EQUIPMENT.

BOTH AT THE BEGINNING AND END OF A REPAIR CHECK THE EQUIPMENT INSULATION LEVELS.

(DISCONNECT THE ELECTRONIC CARDS WHEN MEASURING THE INSULATION).

The insulation-measuring device will have 500 V DC and will be applied to the following points of the circuit:

- Intake rectifier-Earth: Ra> 50 Mohms

- Outlet rectifier-Earth: Ra> 50 Mohms

- Switch l2 - Outlet rectifier: Ra> 50 Mohms

- Control circuit-Earth: Ra> 50 Mohms

Ra: Insulation resistance in Mohms.

In the event that lack of insulation is observed it is likely that this is due to the accumulation of metal dust on the

inside of the equipment.

BOTH AT THE BEGINNING AND END OF A REPAIR, BLOW THE INSIDE OF THE EQUIPMENT WITH

COMPRESSED AIR.

Summary of Contents for 53100000

Page 39: ......