GALA G.E. TIG PULSE

14

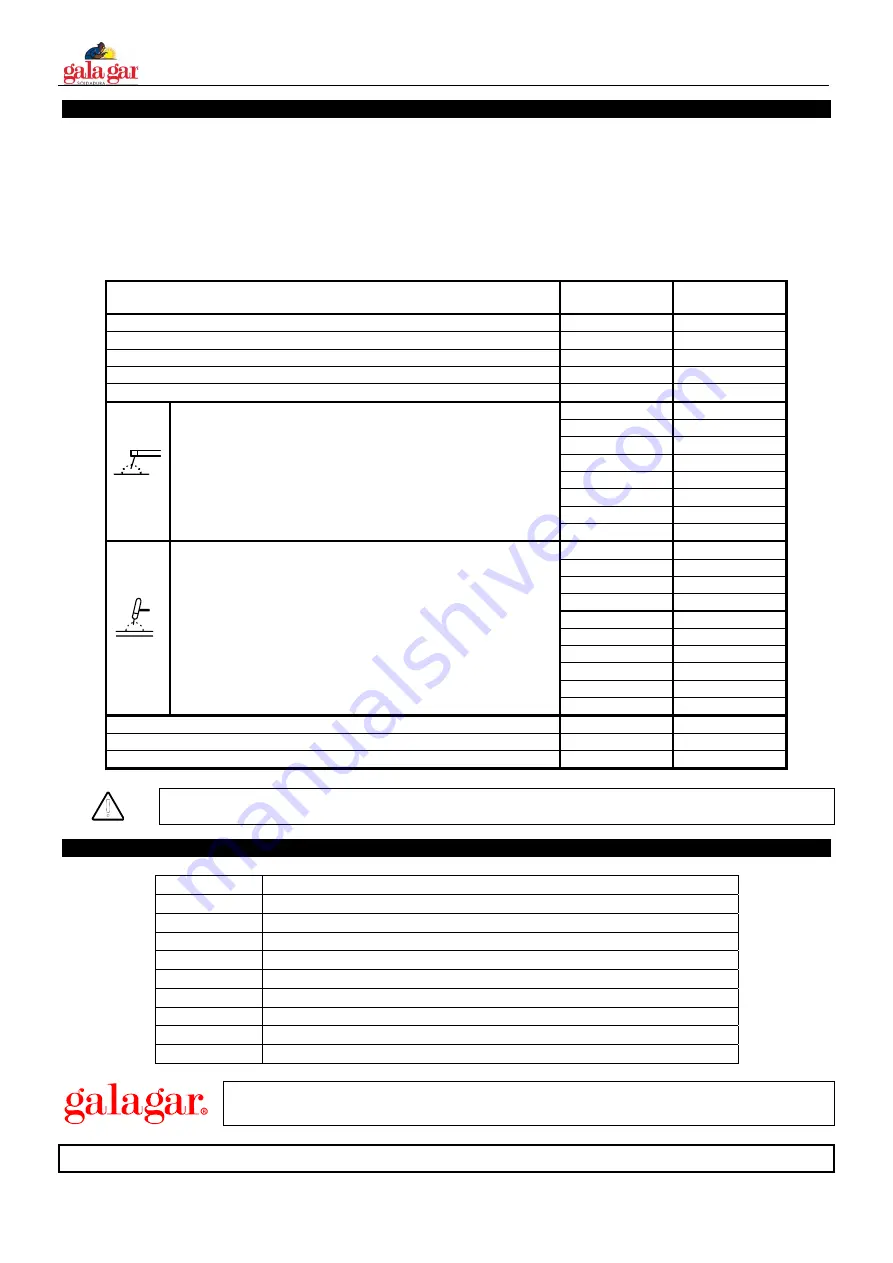

1. GENERAL DESCRIPTION. TECHNICAL CHARACTERISTICS.

The GALA G.E. TIG PULSE SERIES are single-phase electronic technology appliances (INVERTER) designed for use

as a continuous current source for coated electrode and TIG DC welding process. These equipments have a

protection system, which means they can be installed, without any danger of failures, in low quality supply networks

and electrical generating sets.

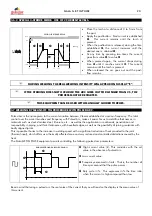

The welding current is controlled by a microprocessor that enables the user to design the most suitable current

form for the welding job. The equipment is able to memorise up to 8 groups of welding parameters (jobs).

Technical characteristics GALA G.E. TIG PULSE. Data according to standard EN 60974-1

Technical characteristics.

GALA 1700

Ref.: 504.00.000

GALA 2000

Ref.: 505.00.000

Supply voltage (U

1

– 1Ph. 50/60 Hz)

230 V ± 15%

230 V ± 15%

Maximum primary intensity (I

1max

)

45 A

45 A

Effective input intensity (I

1eff

)

26 A

26 A

Protection against connection at 400V

•

•

Suitable for generating set.

•

•

No-load voltage (U

2o

)

92 V

92 V

Continuous adjustment margin. (I

2min

- I

2max

)

30

÷

140 A

30

÷

200 A

Maximum welding intensity I

2max

/Duty cycle. (40º C)

140 A/35 %

200 A/35 %

Rated welding intensity X%=100% (I

2n

) (40º C)

80 A

120 A

HOT START function (Arc-striking aid).

•

•

ARC FORCE function (ARC FORCE)

•

•

Antisticking function (ANTISTICKING).

•

•

M.M.A.

Remote control

•

•

TIG continuous adjustment margin. (I

2min

- I

2max

)

5

÷

160 A

5

÷

200 A

Maximum welding intensity I

2max

/Duty cycle. (25º C)

200

A/40

%

Maximum welding intensity I

2max

/Duty cycle. (40º C)

160 A /35 %

200 A /35 %

Rated welding intensity X%=100% (I

2n

) (40º C)

100 A

130 A

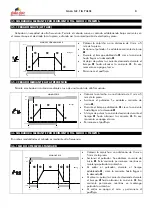

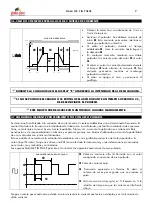

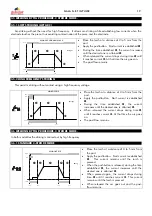

2-S LIFT ARC mode (Selectable pulse arc)

•

•

2-S HF mode (Selectable pulse arc)

•

•

4-S HF mode (Selectable pulse arc)

•

•

SPECIAL 4 T mode (DOUBLE CURRENT)

•

•

Parameter memorisation (2 memories per mode)

•

•

T.I.G.

Remote control

•

•

Mechanical protection degree IP

IP 21

IP 21

Dimensions W x H x L (mm)

161x 334 x 505

161x 334 x 505

Weight (kg).

10,9 Kg

12,5 Kg

NEVER USE THESE WELDING MACHINES TO DEFROST TUBES.

1.1 ACCESSORIES.

REFERENCE DESCRIPTION

002.59.040 Box of complete accessories for electrode welding.

301.44.000.V Electronic protection shield (Automatic-Professional).

376.00.000 Argon pressure reducing valve – Mod. EN 2

376.00.515 Argon pressure reducing valve with rotameter – Mod. EN 2

180.51.714 Torch model SR 17, with 4 m and pushbutton

190.52.614 Torch model SR 17, with 8 m and pushbutton

504.12.080 TIG torch accessory connector assembly.

505.12.095 Remote control for electrode (MD MMA 2000 PULSE)

505.12.096 Remote pedal for TIG (MD TIG 2000 PULSE)

GALA GAR has a complete range of welding accessories where you can find those most

suited to your needs.

USE ONLY THE RECOMMENDED SPARE PARTS AND ACCESSORIES

.