GALA G.E. TIG PULSE

18

3.4 WELDING BY TIG PROCEDURE.

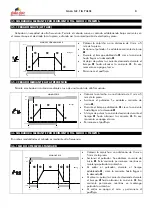

In TIG welding we must only use straight polarity, placing the welding torch in the negative pole. In addition, in

the installation, we must place a gas bottle O, (normally Argon), which we will connect to the machine through

pressure regulator N as seen in the figure below.

N- NEGATIVE POLE. TIG WELDING TORCH.

P- WELDING EARTH CLAMP.

O-TORCH GAS OUTPUT.

M- CONTROL CONNECTOR. (TORCH)

L- GAS INTAKE. (GAS BOTTLE)

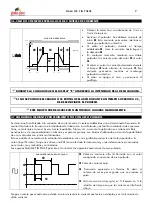

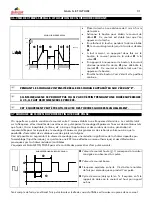

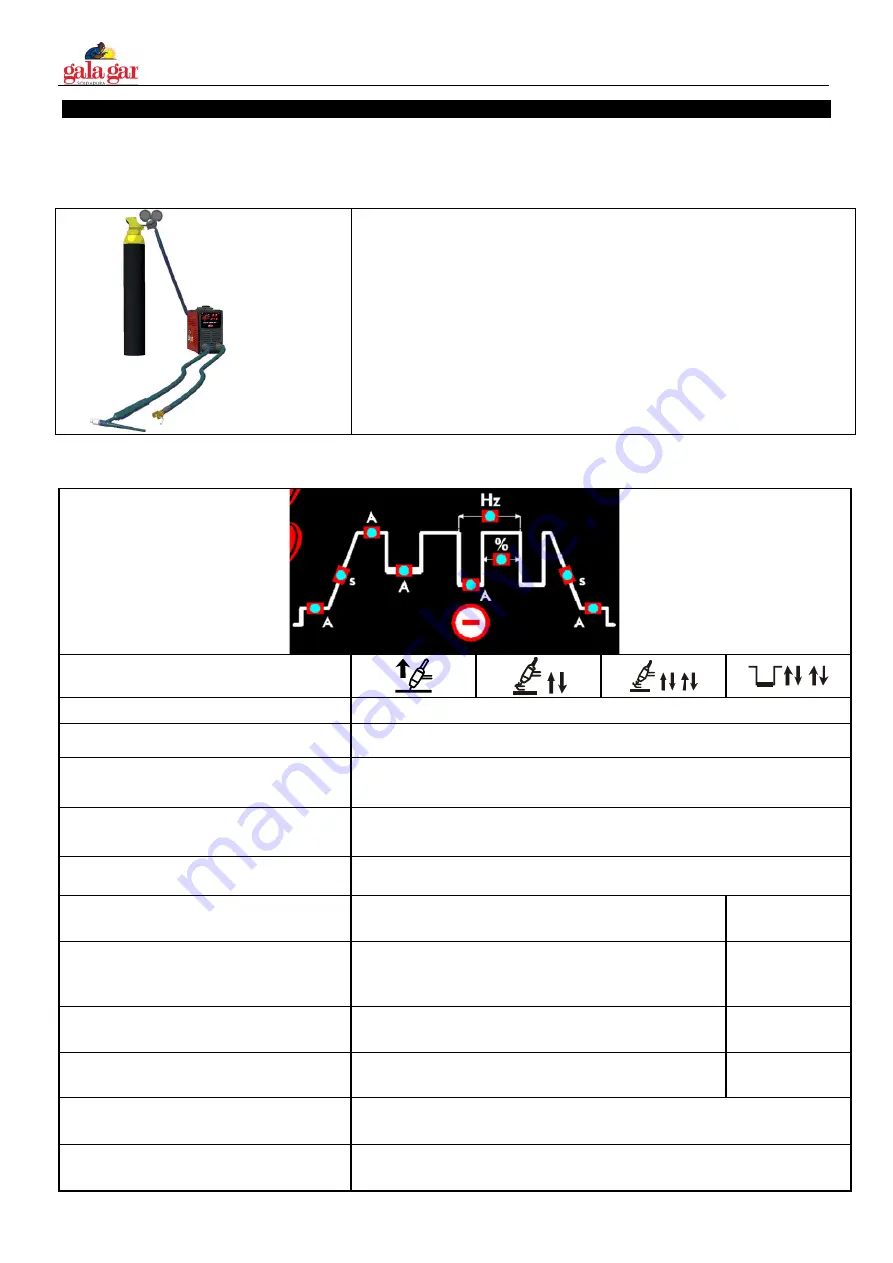

In TIG welding it is possible to set the following parameters related to the current:

Welding current

(A) (I

2

)

5 – 160 / 5 - 200

Down ramp (s)

(t

dws

)

0 - 10

Crater current

(A)

(I

e

)

5 – 160 / 5 - 200

The maximum value is limited to I

2

(

)

Start current (5- I

2

A)

(I

s

)

5 – 160 / 5 - 200

The maximum value is limited to I

2

(

)

Up ramp (0- 10 s)

(t

ups

)

0 - 10

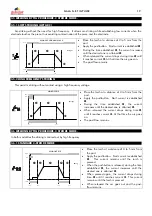

Second current level (5- 160/200

A)

Not available

5 – 160 / 5 - 200

Basic current A. Pulsed (

A)

5 – 160 / 5 - 200

The maximum value is limited to I

2

(

) and varies

proportionally with it. (Section 3.5)

Not available

Pulse frequency (Hz)

0.1 - 500

Not available

Duty cycle (20-80 %)

20 - 80

Not available

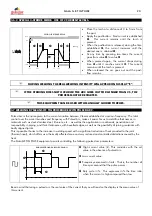

Remote control.

It regulates between the value assigned to start current

(I

s

) and the welding

current value

(I

2

)

Pre- Flow ; Post-flow (s)

0.1 – 5.0 s ; 0.1 – 10.0 s