GAR CUT (V. INDUSTRIAL). Instructions Manual

21

3.6 RECOMMENDATIONS RESPECT TO CUTTING CYCLE.

The correct settings of the times indicated are essential for the equipment to work perfectly. Air must exist

before the arc is ignited, as if this does not exist, the torch head would be seriously deteriorated due to

the formation of the electric arc inside. The time that elapses between the appearance of air and the

ignition of the arc is what we have called preflow. We suggest the routine of slightly pressing the

pushbutton in order to get the air to come out without producing ignition. After checking the existence of

air we can now ignite the arc by pressing the pushbutton continuously.

The post-flow time is also very important with respect to the working life of the cutting torch. This time

delimits the degree of cooling of the torch after having carried out a cutting process. We do not

recommend reducing the value of this time unless work is only being carried out in the minimum cutting

position where 40 sec. post flow can be used.

The pilot arc time adjustment can be modified by prolonging it. Too long a pilot arc time is not suitable

as the life of the consumable elements decreases. However this time can be adapted to your needs.

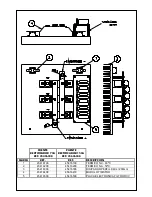

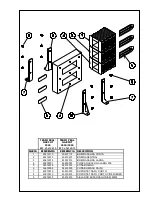

3.7 INTERNAL PROTECTION ELEMENTS

The GAR CUT (V. Industrial) Plasma cutting equipment have the following internal protection elements:

- GENERAL SAFETY PROTECTION:

It forces the use of a tool to connect and disconnect the plasma torch (safety cap).

WARNING !

IF THE SAFETY CAP OF THE TORCH HAS NOT BEEN INSERTED, THE MACHINE WILL NOT BE

OPERATIVE.

- PROTECTION AGAINST OVERHEATING. THERMAL PROTECTION (L3).

As soon as the transformer reaches a high temperature, a protection mechanism is activated which prevents

the cutting operation from being continued. This is indicated by means of the amber light L3 situated on the

front of the machine which will stay on when the torch pushbutton is pressed, as there is no cutting cycle.

- PROTECTION AGAINST ABSENCE OF PRESSURE IN PNEUMATIC CIRCUIT. (L2).

It is important for the air flow in the torch outlet to correspond to that given in table before, in order to

prevent deterioration caused by overheating of the torch. The machine has a pressurestat which prevents the

cutting operation if the intake pressure is above a limit value. This is indicated by a red pilot light L2 which will

stay on if the pressure is not correct. The pressurestat is on the inside of the equipment next to the regulating

filter. This pressurestat has an adjustment screw which enables the value of the minimum pressure to be

established (around 4.6 bar).

- PROTECTION AGAINST DIRECT CONTACTS IN THE PISTOL BODY.

In order to prevent dangerous voltages when carrying out work on the torch body (replacement of

consumable components, for example), the torch has a safety system (activated by the nozzle-holder) which

cancels the action of the pushbutton. However it must be borne in mind that the body of the torch must always

be handled with the MACHINE DISCONNECTED.

- PROTECTION AGAINST CUTTING WITHOUT THE EXISTENCE OF ELECTRICAL EARTH.

In order to prevent cutting without the existence of an electrical earth (cutting with the pilot arc) the

equipment has a cutting current detection system which times the pilot arc.