GAR CUT (V. INDUSTRIAL). Instructions Manual

22

CHAPTER 4. MAINTENANCE OPERATIONS. RECOMMENDATIONS.

In order for the equipment to have a long life we must follow some essential rules for maintenance and use.

Abide by these recommendations.

CORRECT MAINTENANCE OF THE EQUIPMENT WILL AVOID A GREAT PERCENTAGE OF FAULTS.

Before carrying out any operation on the machine or torch, we must place switch l1 of the equipment in "O"

position of machine disconnected.

Specialized personnel must handle the machine to carry out maintenance and repair operations.

BLOW THE INSIDE OF THE MACHINE WITH COMPRESSED AIR FROM TIME TO TIME.

The accumulation on the inside of metal dust is one of the main causes of breakdowns in this type of

equipment as they are subject to the great amount of pollution caused by the cutting process. Although the

equipment has an anti-pollution system (the fan does not start up until the machine has reached a certain

temperature), the equipment must be separated from the cutting place, avoiding placing it near to. Keeping the

machine clean and dry is essential. The inside must be blown as required. We must avoid any anomaly or

deterioration due to the accumulation of dust. Blow the two inside volumes of the equipment with clean dry

compressed air.

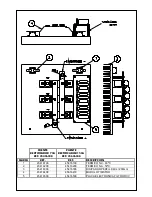

- Control volume (upper): Electronic plates, contactors, auxiliary transformer.

- Power volume (lower): Rectifier, main transformer, switches.

FROM TIME TO TIME DISCHARGE THE WATER WHICH HAS CONDENSATED ON THE FILTER-

REGULATOR

Control the non-existence of liquid in the glass of filter F situated on the rear of the apparatus. When the air

intake is disconnected an automatic discharge takes place. The discharge can be done manually by pressing

the valve that exists on the lower part of the glass.

PLACE THE EQUIPMENT SOMEWHERE WHERE CLEAN AIR IS RENEWED.

The machine ventilations must be kept free. It must be located in a place where clean air is renewed.

KEEP THE MACHINE PANELS CLOSED.

DO NOT DISCONNECT THE MACHINE IF IT IS HOT.

If you have finished the cutting work do not disconnect the machine immediately, wait until the inner cooling

system has totally cooled it.

4.1 MAINTENANCE OF THE PLASMA TORCH. GENERAL RECOMMENDATIONS.

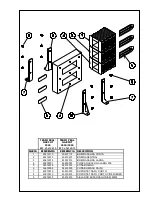

The plasma torch is the main element of the system. A badly maintained torch makes the cutting operation

difficult, speeding up the wear of the consumable elements.

The plasma torch has a safety system which prevents the existence of dangerous voltages when the

consumable elements are changed or repaired. However always remember to:

DISCONNECT THE MACHINE WHEN HANDLING THE TORCH BODY

IMMEDIATELY CHANGE A WORN ELECTRODE OR A NOZZLE.

We can say that there is wear:

- If the middle hole of the electrode is 2 mm.

- If the nozzle has an irregular hole or increased diameter. In this case there will be no perpendicularity in

the cutting section.