SMART 200 TIG PULSE

30

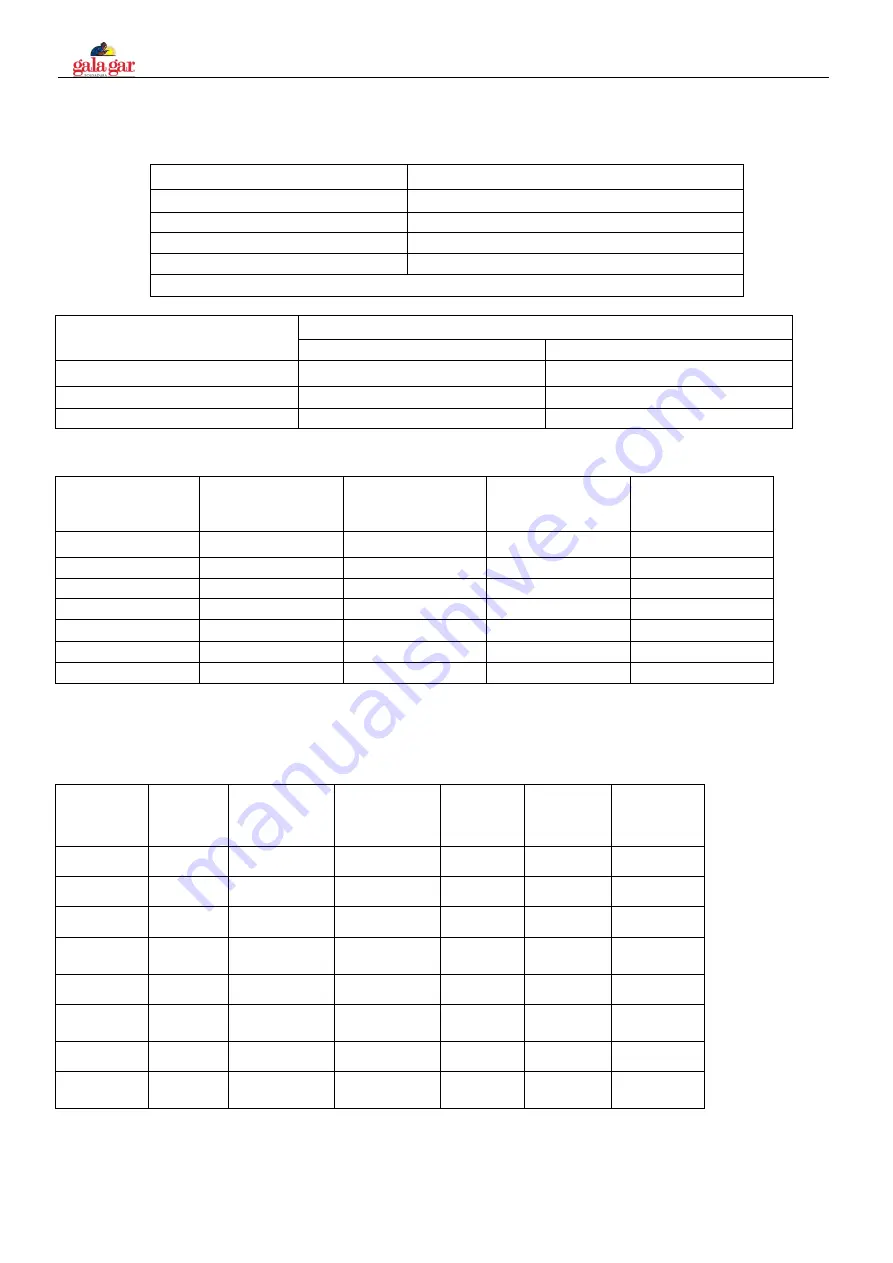

TIG Parameters Matching

The corresponding relationship between gas nozzle diameter and electrode diameter

Gas nozzle diameter/mm

Electrode diameter/mm

6.4

0.5

8

1.0

9.5

1.6 or 2.4

11.1

3.2

Notice: the above parameters originate from(Welding Dictionary)P142, Volume 1 of Edition 2.

Welding current range/A

DC positive connection

Gas nozzle diameter/mm

Gas flow rate/L

·

min

-1

10-100

4-9.5

4-5

101-150

4-9.5

4-7

151-200

6-13

6-8

Tungsten electrode shape and the welding current range (DCEP)

tungsten electrode

diameter /mm

sharpened of the

electrode

diameter/mm

angle of cone(

°

)

background

current/A

pulse current

1.0

0.125

12

2-15

2-25

1.0

0.25

20

5-30

5-60

1.6

0.5

25

8-50

8-100

1.6

0.8

30

10-70

10-140

2.4

0.8

35

12-90

12-180

2.4

1.1

45

15-150

15-250

3.2

1.1

60

20-200

20-300

Notice: the above parameters originate from(Welding Dictionary)P149, Volume 1 of Edition 2.

TIG of stainless steel (single run welding)

Workpiece

thickness

/mm

Joint

form

tungsten

electrode

diameter/mm

welding wire

diameter/mm

Argon gas

flow rate/

L

·

min

-1

welding

current

(DCEP)

Welding

speed/

cm

·

min

-1

0.8

Butt joint

1.0

1.6

5

20-50

66

1.0

Butt joint

1.6

1.6

5

50-80

56

1.5

Butt joint

1.6

1.6

7

65-105

30

1.5

Corner

joint

1.6

1.6

7

75-125

25

2.4

Butt joint

1.6

2.4

7

85-125

30

2.4

Corner

joint

1.6

2.4

7

95-135

25

3.2

Butt joint

1.6

2.4

7

100-135

30

3.2

Corner

joint

1.6

2.4

7

115-145

25

Notice: the above parameters originate from(Welding Dictionary)P150, Volume 1 of Edition 2.