- 6 -

User Manual

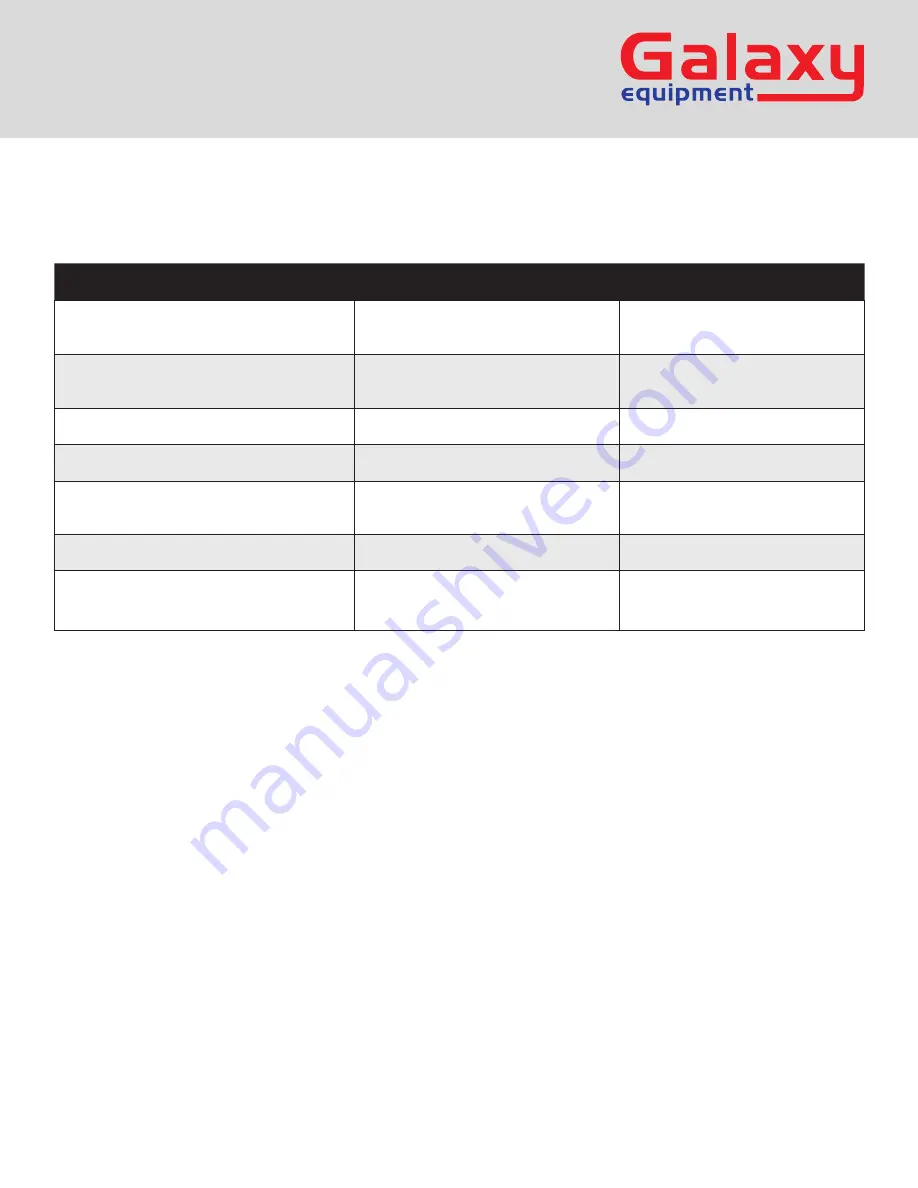

Troubleshooting

Trouble

Possible Causes

Solution

The axles can’t work when

operating the machine

Poor contact of the electrical equip-

ment

Check the Plug

The mixing bowl is out of position

Moving direction is not correct

Change

Leaks oil

Sealing washer is damaged

Change

Difficult to move the bowl up and down

Slideway is rusted

Clean the slideway and lubricate

The motor is overheated

and speed is down

The voltage is not enough,

or incorrect speed

Check the voltage or use

lower speed

Noise and overheating

Poor lubrication

Add or change lubrication

Mixer touches bowl

The mixing device or bowl deformed

Repair or change the bowl

or mixing device