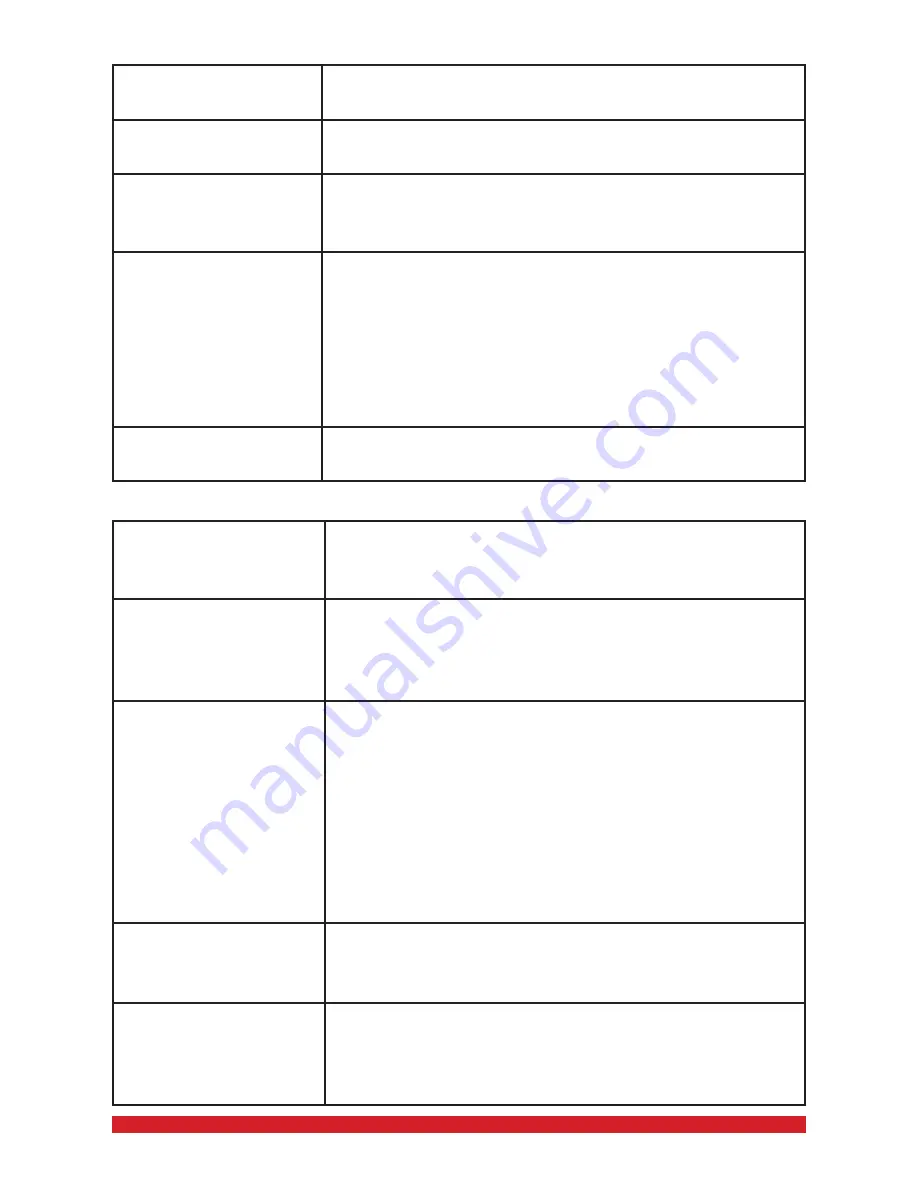

Unqualified staples

Use only our standard 26/6 & 26/8 staples. See

Page 4.

Incorrect staple type

or specification

Use only our standard 26/6 & 26/8 staples. See

Page 4.

Staple Pusher has

been put in the wrong

direction

The Staple Pusher should be shown towards the

rear of the machine. See Page 3.

Residue is inside the

Staple Head

First, remove the Staple Head from the machine

and then unscrew the front plate of the Staple Head.

Clean the Staple Head and then re-install it to the

machine. Make sure the Staple Head latch is locked

before you operate the machine. Follow the

instructions on Page 3 to remove/install the Staple

Heads.

Staple Pusher is

scratched or worn out

Follow the instructions on Page 3 to change the

Staple Pusher.

Missing staples or un-qualified staple in-put:

If you cannot fold or if an un-qualified booklet has been folded & stapled:

Settings for the Fold

& Staple features are

not correctly set

Follow the instructions on Page 2 to set up the Fold

& Staple features correctly.

Too many sheets

are inserted or the

material is too rigid

1. Do not insert more than 16 sheets of paper into

one run.

2. Do not insert materials that are too thick or too

rigid. Do not insert materials other than paper.

Folding line is not

located in the centre

of the booklet, or is at

a slanted angle

1. Properly adjust the Left & Right Side Guides.

If the Side Guides are too far apart, paper can be

unparallel as it is inserted into the machine. On the

other hand, if the Side Guides are set too tightly,

paper can curl up during folding, which can result in

incorrect stapling. See Page 5 for instructions.

2. Properly adjust the Paper Depth Adjustment

Knob, so that the machine folds in the centre of the

sheets. See Page 5 for instructions.

Dirty rollers

Clean rollers using a soft and damp cloth. Never use

chemical or alcohol base liquidsas they may

damage the roller.

The 2 staples are not

properly centered in

the booklet

1. Properly adjust the Left & Right Side Guides.

See Page 5.

2. Re-install Staple Heads to the correct positions.

See Page 3.

11