INTRODUCTION

5

1.3.4 RUNNING-IN

Every machine is scrupulously adjusted and tested before delivery.

A new machine, however, must be used carefully for the first 100 hours, in order to ensure proper running-in of the

various components.

If the machine is subjected to excessive work load at the beginning of operation, its potential productivity and its

functionality will be shortly and untimely reduced.

Every new machine must be used carefully, paying special attention to the following instructions:

q

After the start, let the engine idle for 5 minutes, in such a way as to warm it up gradually before actual operation.

q

Avoid operating the machine with the limit loads allowed or at high speed.

q

Avoid abrupt starts or accelerations, useless sudden decelerations and abrupt reversals.

SYNTHETIC BIODEGRADABLE OIL TYPE HEES

For machines in which synthetic biodegradable oil type HEES is used, perform the following operations in addition

to the standard maintenance operations:

q

After the first 50 hours of operation, change the hydraulic circuit drain filter.

q

After the first 500 hours of operation, change the hydraulic circuit oil.

IMPORTANT

q

When changing the oil filters (cartridges), check their inner part to make sure that there are no deposits.

If considerable deposits are observed, find out what may have caused them before starting the machine.

q

The number of operating hours is indicated by the hour meter.

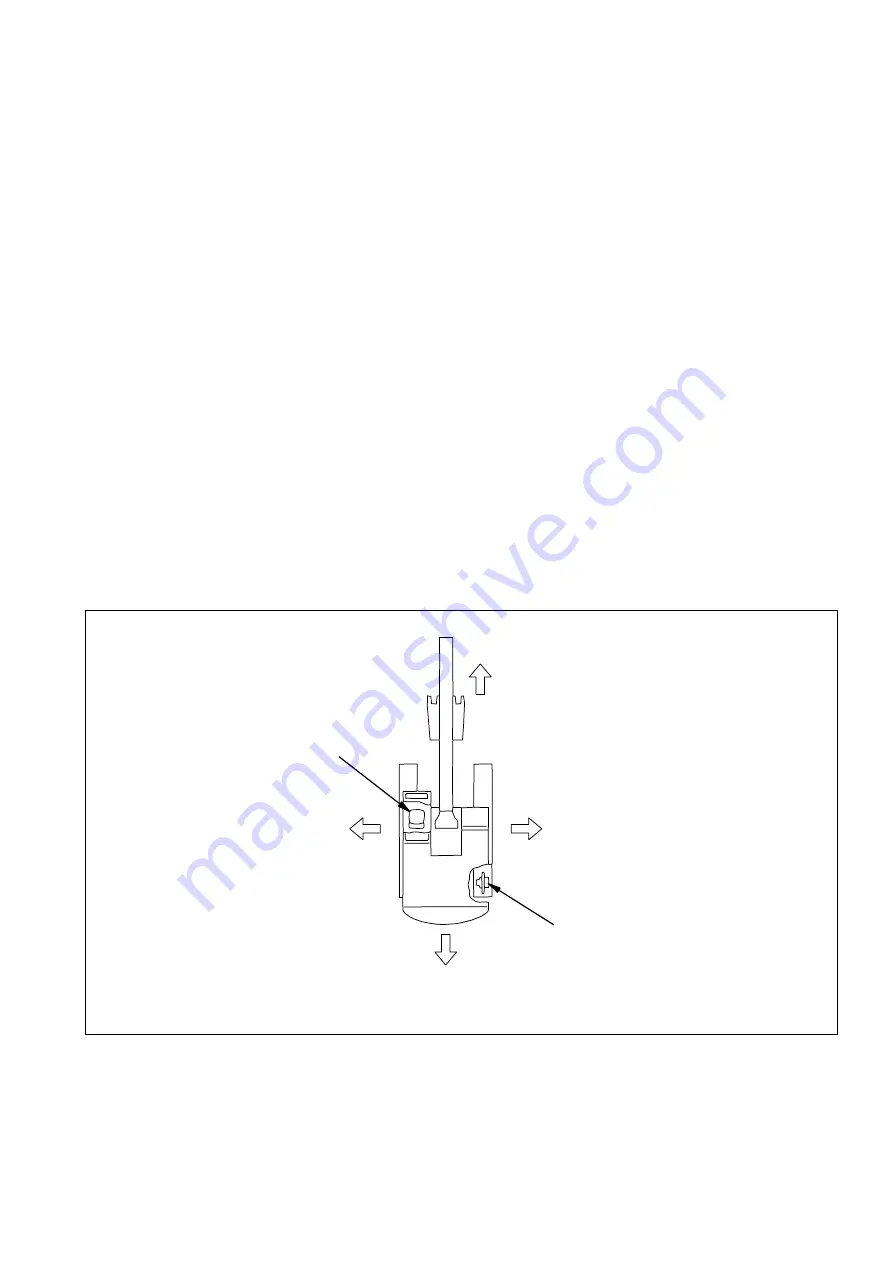

1.3.5 POSITIONS AND DIRECTIONS OF THE MACHINE

In this manual, the terms front/forward, rear/backward, left, and right refer to the travel direction as seen from the

operator seat when it is facing the front and the sprocket is at the rear of the machine.

Front

Operator's seat

Sprocket

Left

Right

Rear

RYA00050