B.

Motor Rotation

The machine hand wheel must turn clockwise when viewed from the hand wheel end. The

oil pump will not function when the machine operates in reverse rotation. To check

rotation, turn on the motor and use the foot pedal to turn over the machine slowly, while

checking direction. Do not run the machine for an extended period. If the hand wheel turns

in the wrong direction, stop immediately. Turn off the motor and unplug power. Reverse

motor direction by rewiring connections or reprogramming as appropriate. For single phase

motors, a diagram may be found for reverse wiring, either on the specification plate or

inside the wire connection access opening. For 3-phase motors, exchange connections of

any two of the three “hot legs” Servomotors are reversed by programming. Check motor

manual for method of programming rotation.

C.

Motor Speed

Maximum recommended sewing speed is 4200 stitches per minute. Pulley combination and

or motor settings have been chosen to reflect this recommendation. The sewing machine is

capable to speeds up to, 5800 stitches per minute. At such speeds; however, wear life of

parts become a problem. Of particular concern would be wear to top feed parts; especially

the top feed belt, clutches and eccentric tie rod ends.

D.

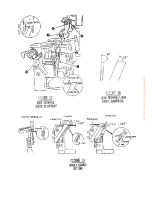

Threading

Thread the sewing machine as shown on the threading diagram, Figure 04.

E.

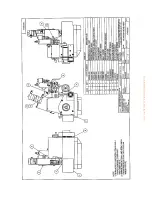

Flange Guide Adjustment

Adjust the flange guide to control the flange material. Material should be able to move

freely from under the sewing machine stand, around the curved flange guard, and through

The flange guide to feed straight into the machine. Referring to Figure 05, adjust the flange

guide to control the flange. Set the panel guide to guide the pad into the sewing machine.

F.

Optional Flange Handling Equipment

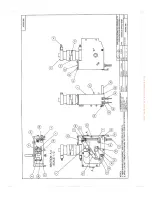

1.) Flange Rack

An optional flange rack is available for the Galkin 3350-X5 Flanger. If this option

has been purchased, it is to be mounted to the vertical supports of the machine stand. Note

that, when held between the reel flanges, flange material should guide straight through the

flange guide at the front of the table.

Flange rolls can be loaded to the rack by lifting one end of the shaft and sliding the

roll into position making sure it does not restrict the flange material from

feeding to the flange guide.

From the library of: Diamond

Needle

Corp

Summary of Contents for GAP-X5

Page 2: ...From the library of Diamond Needle Corp...

Page 3: ...From the library of Diamond Needle Corp...

Page 13: ...Lubrication From the library of Diamond Needle Corp...

Page 14: ...Checking the cartridge filter and replacing it From the library of Diamond Needle Corp...

Page 15: ...From the library of Diamond Needle Corp...

Page 16: ...From the library of Diamond Needle Corp...

Page 17: ...From the library of Diamond Needle Corp...

Page 18: ...From the library of Diamond Needle Corp...

Page 19: ...From the library of Diamond Needle Corp...

Page 20: ...From the library of Diamond Needle Corp...

Page 21: ...From the library of Diamond Needle Corp...

Page 22: ...From the library of Diamond Needle Corp...

Page 23: ...From the library of Diamond Needle Corp...

Page 24: ...From the library of Diamond Needle Corp...

Page 25: ...From the library of Diamond Needle Corp...

Page 26: ...From the library of Diamond Needle Corp...

Page 27: ...From the library of Diamond Needle Corp...

Page 28: ...FRAME COMPONENTS 1 From the library of Diamond Needle Corp...

Page 30: ...FRAME COMPONENTS 2 From the library of Diamond Needle Corp...

Page 32: ...CRANKSHAFT COMPONENTS From the library of Diamond Needle Corp...

Page 34: ...NEEDLE DRIVING SHAFT COMPONENTS From the library of Diamond Needle Corp...

Page 36: ...FEED MECHANISM COMPONENTS 1 From the library of Diamond Needle Corp...

Page 42: ...CHAIN LOOPER COMPONENTS From the library of Diamond Needle Corp...

Page 44: ...THREAD TENSION COMPONENTS From the library of Diamond Needle Corp...

Page 46: ...LOWER KNIFE COMPONENTS From the library of Diamond Needle Corp...

Page 48: ...Upper Knife Components From the library of Diamond Needle Corp...

Page 50: ...LUBRICATION MECHANISM COMPONENTS From the library of Diamond Needle Corp...

Page 52: ...THREAD STAND COMPONENTS From the library of Diamond Needle Corp...

Page 54: ...From the library of Diamond Needle Corp...

Page 55: ...From the library of Diamond Needle Corp...

Page 56: ...From the library of Diamond Needle Corp...

Page 57: ...From the library of Diamond Needle Corp...

Page 58: ...From the library of Diamond Needle Corp...

Page 59: ...From the library of Diamond Needle Corp...

Page 60: ...From the library of Diamond Needle Corp...

Page 61: ...From the library of Diamond Needle Corp...