3.

Stage 2

Vertical Delivery Pipe Assys Installation Procedure

Components Supplied by PEC

Front & Rear Vertical Pipe Assys

Head Cabinet Assy. (Fitted with Grade ID Decals)

Head Cabinet mtg. Brkts

Flexible Safety Hose Assys

External Hose Assy, fitted with Nozzles, Grade Covers & Gas Guards

Nozzle Grade ID Decals

Vent Box Assy Front & Rear (2 x Top Caps)

Serial Name Plate. (Name Plate to be Adhered to Top LH corner of GRP head access Door)

•

Installation Procedure

•

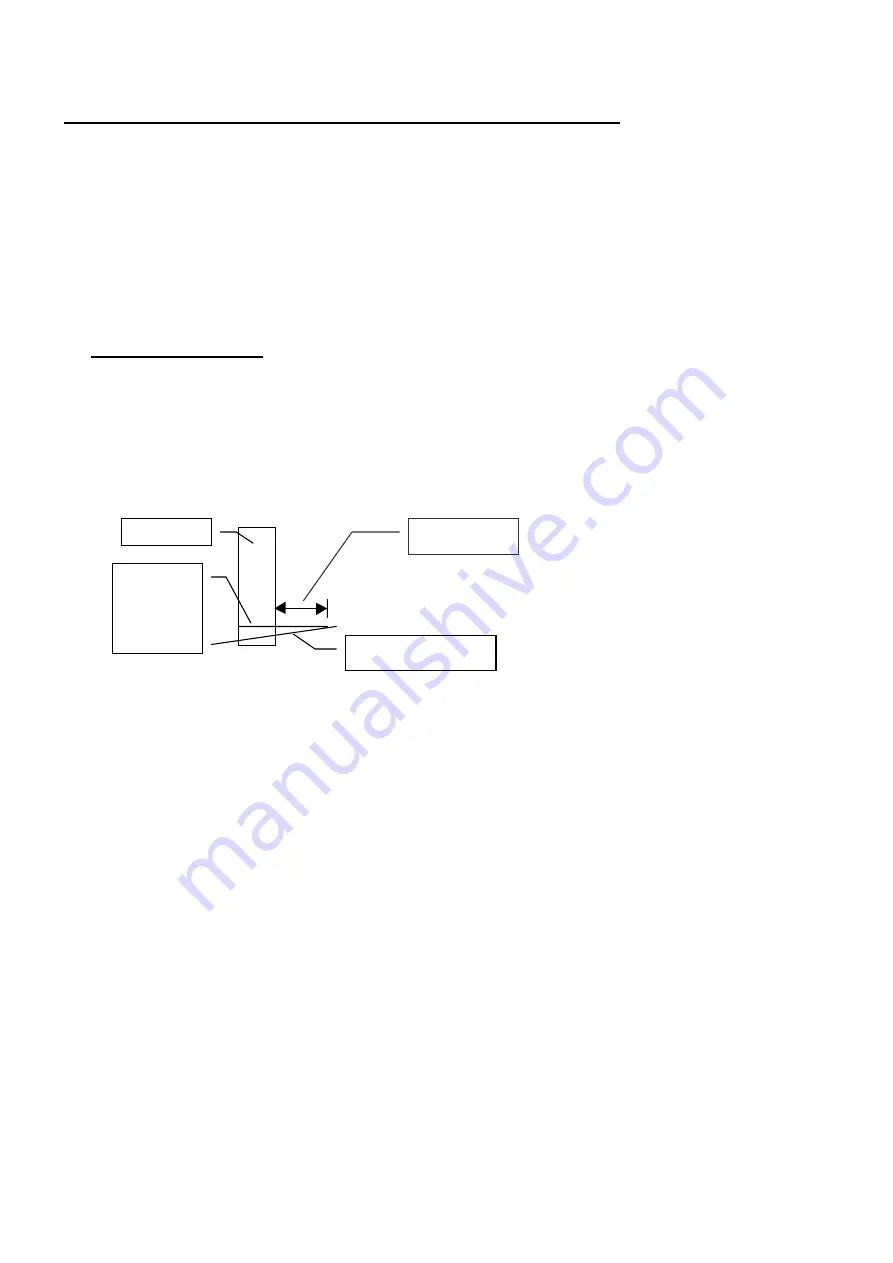

Using a Sprit level find the highest point on Forecourt out to a distance of 160 mm from Main

Column(in any direction).Transfer this point onto Front face of Column (Front =Sump @ right hand

side of Column) clearly mark as datum point on Column Face. (This is a datum point to start

measuring from regards positions of components & mtg. brkts. etc. (See Sketch below) This point

must be established to obtain mounting heights & ground clearances etc. for Final Cladding.

•

From the above, mentioned Datum Line, transfer & mark a point 2.3 m Vertically up Column. If

preferred a second but lower point could be marked @ 1.405m.up Having both these Datum points

marked on Column could be advantageous as they could then both serve as a double checks. Note:

Marks should be made Horizontally, as they will later be used to align Vertical Pipe & Holster Assy

Mtg. Brkts. etc. (Details refer Fig 4 )

•

Place Front Vertical Pipe Assy 89826 onto front face of Column, top angled section of Pipe Assy.

should be pointing out to right hand side. (eg. towards Sump ) (Note: Front of Dispenser = Column on

Left with Sump on Right) Both of the middle two Mounting brkts on Vertical Pipe Assy have a right

angle Lug welded to them, these Lugs are location lugs & should be positioned up against right hand

face of column.

•

With Lugs positioned against Column side face, slide Pipe Assy up until top face of second horizontal

Brkt. up Assy aligns with lower mark 1405.4mm Son Column and/or top face of second horizontal

Brkt. down Assy aligns with upper mark on Column. Secure into position with “G” or “F” Clamps.

(Or Ratchet Ties)

•

Check Column Stops on second & third horizontal brkts are hard against Column Face, also check

Vertical Pipe Assy is vertical. (If not this could indicate Column is not truly Vertical, in this instance

move either top or bottom of Pipe Assy. to obtain true Vertical reading, secure Clamps, recheck

heights from Forecourt datum marks.

160 mm

Column

Mark

Level

on

Column

Forecourt

Summary of Contents for Apollo 3000

Page 1: ...Apollo 3000 Set up Installation Parts Manual...

Page 2: ......

Page 4: ......

Page 15: ...11 Float Switch 89778 Float Swt Mtg Angle only 89749 Float Switch Bracket Assembly...

Page 26: ...22 Stage 1 Installation Procedure Sump Column Position Fig 2...

Page 27: ...23 file gme c docum pec apollo2 fig 2 manual doc Stage 1 Installation Service Area Spec Fig 3...

Page 28: ...24 Stage 1 Installation Procedure Mounting Positions Fig 4...

Page 29: ...25 Stage 3 Vent Box Installation Vent Box Position Sealing Spec Fig 5...