6

FC66000611 - 07

È severamente vietata la riproduzione anche parziale di questo manuale / All copying, even partial, of this manual is strictly forbidden

5.2

INSTALLATION FOR THE FC,FF,FP,FU MODEL

WARNING: The FC, FF built-in models must not be accessible

to the public

The air outlets should not be placed immediately under a socketFor the

FC,

FF

flush-mounted model, perform the connection between the fan coil and

the ducts, and place damping material between the duct and the unit.

The ducts, in particular the outlet ones, must be insulated.

In order to avoid air back suction on the fan coil, keep a minimum distance

between the air outlet and recovered air flow as shown in figure 5 page

29.

The minimum installation height should not be lower than 1.8 metres from

floor level. Provide for an inspection port to the unit.

5.3

ELECTRICAL CONNECTIONS

Carry out the electrical wiring after having turned the power off

in

compliance with the current safety regulations

following the

diagram of the figure 6 and its caption.

Check that the power supply corresponds to the rated power reported

on the unit nameplate.

Electric connections in dotted lines should be carried out by the installer.

An omnipolar mains isolator in overvoltage category III must be present for

every fan coil in the power supply line.

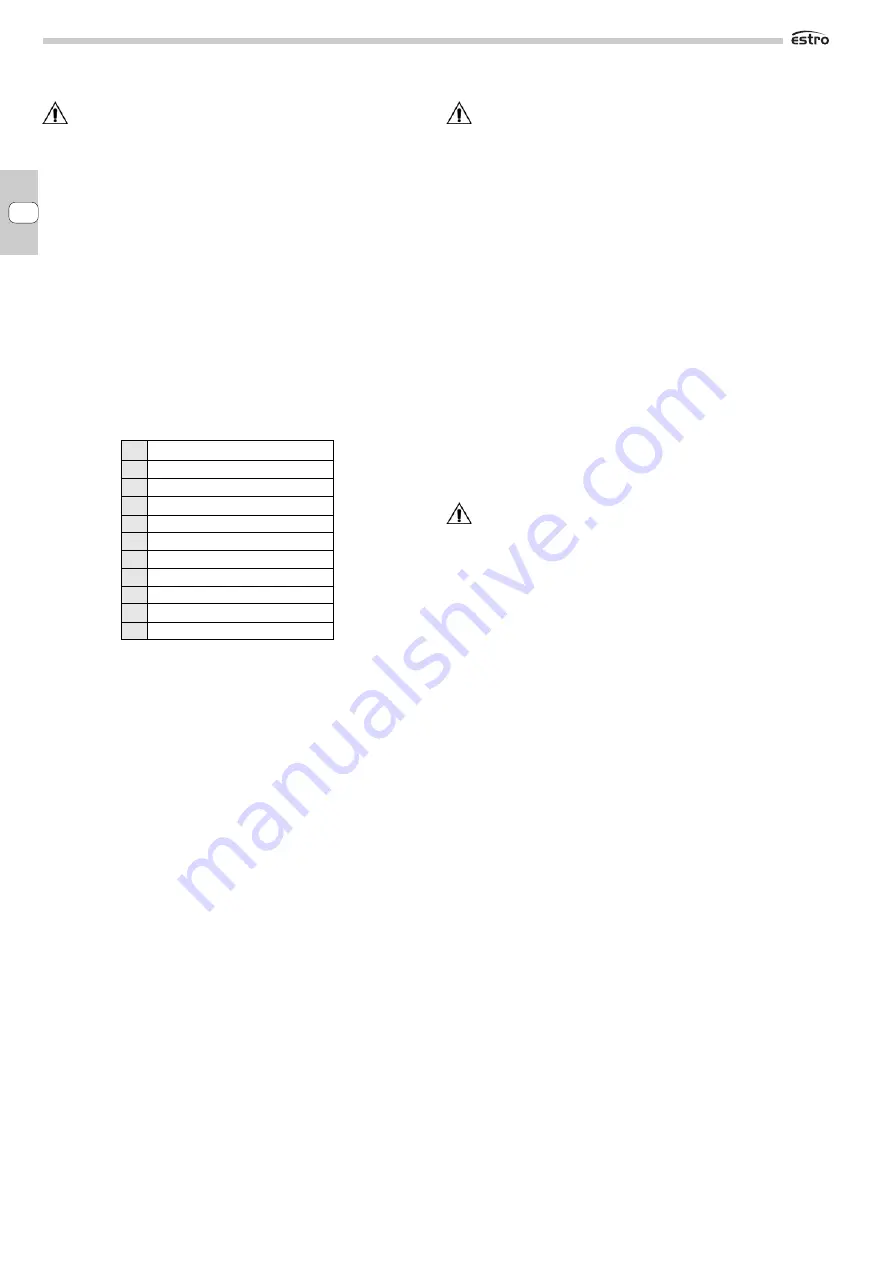

On the wiring diagram the following abbreviations are used:

MODELS WITH 6-SPEED MOTORS (FIGURE 7)

The connections indicated must be made by the installer.

Make the electrical connections with the power supply

disconnected, in accordance with current safety regulations.

Check that the mains electricity supply is compatible with the

voltage shown on the unit rating plate.

Each fan coil requires an individual electric socket and a switch

with a suitable safety fuse.

BK

Black, speed 6

BU

Blue, speed 5

GY

Grey, speed 4

BN

Brown, speed 3

V T

Purple, speed 2

RD

Red, speed 1

CN

Fast-on connector

F

Safety fuse (not supplied)

IL

Circuit breaker (not supplied)

M

Fan motor

WH

White = common

6

TEST RUN

Check that the unit is perfectly levelled and that the drain pipe is not

obstructed (rubble deposits, etc.).

Check that the water connections (to the heat exchanger and water

drainage) are sealed.

Check that the electrical wiring is perfectly tight.

Be sure that the air purge of the heat exchanger has been carried out.

Replace the cabinet (where existing).

Turn on the power supply and check the unit running.

7

USE

To use the fan coil unit, refer to the instructions of the control panel,

available as accessory.

Air outlet grids on the cover cabinet (FL, FP and FU) can be turned 180°

to direct the flow into the room or towards the wall on which the unit is

mounted.

The grids and the side doors are snapped onto the cabinet. Before

removing them in order to change their position, cut the power off and wear

protective gloves.

BK

Black = max. speed

BU

Blue = medium speed

CN

Fast-on connector

F

Fuse, not supplied

GNYE

Yellow/Green = earth

IL

Line switch, not supplied

M

Motor

RD

Red = min. speed

WH

White = common

1

To command (accessory)

8

MAINTENANCE

WARNING: Maintenance must only be carried out by an

assistance centre authorised by the manufacturer or by qualified

personnel.

For safety reasons before carrying out any maintenance or

cleaning operation, switch off the unit turning the selection

switch to “Stop” and the power supply switch on position 0 (OFF).

Be careful during any maintenance operation; you could get

injured by some metal parts; use protective work gloves.

The estro fan coils do no require any particular maintenance operation:

only the periodical cleaning of the air filter should be carried out.

It is necessary to carry out a running in period of 100 hours in order to

eliminate all mechanical friction.

The starting up must be carried out at the maximum speed.

For good operation of the estro fan coils follow the instructions below:

- keep the air filter clean;

- do not pour liquids into the unit;

- do not introduce metal parts through the air outlet grid.

- keep the air inlet and outlet free at all times.

Each time the machine is turned on after being idle for a long period, ensure

there is no air in the heat exchanger.

Before using the unit for air conditions, check that:

- condensate drainage is performed correctly:

- the heat exchanger fins are not obstructed by deposits of dirt.

If necessary clean the fins with low pressure compressed air or steam

without damaging them.

9

CLEANING

WARNING: The filter must only be cleaned by an assistance

centre authorised by the manufacturer or by qualified personnel.

For safety reasons before carrying out any maintenance or

cleaning operation switch off the unit turning the selection

switch to “Stop” and the power supply switch on 0 (OFF).

Clean the filter at least once a month and in any case before using the unit

(before the heating or the air conditioning season).

For cleaning the air filter proceed as follows (figure 8, page 32):

- model

FL

: turn the screws 90°, which secure the filter to the cover

cabinet, to 1/4 turn and remove the filter;

- model

FP

: Unscrew the screws holding the filter to the cabinet and

remove the filter;

- model

FF

: Unscrew the screws to remove the platelets, and remove the

filter

- flush-mounted model

FC

: reach the fan coil through the inspection panel

and remove the filter, turning the locking brackets 90°;

- model

FU

: remove the air filters that are inside the intake grids located

on the front panel of the cover cabinet;

- clean the filter with lukewarm water , or in case of dry dust, with

compressed air;

- reassemble the filter after having dried it up.

It is recommended to replace the air filter yearly, and to use original spare

parts.; the fan coil model is reported on the nameplate located on the

internal part of the side panel of the unit.

To clean the unit cabinet proceed as follows:

- use a soft cloth;

- do not pour any liquid on the unit, as this could cause electrical shocks

or damage the components inside it;

- do not use any aggressive chemical solvents; do not use very hot water

to clean the air outlet grid.

GB