LCX

RG66010687_rev.00

25

Proactive action of an Electronic Expansion Valve:

In the event of a compressor on/off request:

The electronic driver pre-positions the valve at a point very near the final equilibrium point.

A status of equilibrium is quickly reached with small adjustments.

The electronic expansion valve becomes an active, rather than passive, component within

the system.

The transient time is greatly reduced.

Overall the system is more efficient, with higher EERs and therefore greater savings.

7.6

STOPPING THE UNIT

The unit can be stopped by pressing the "OFF" button on the front panel, by turning off the main switch,

or via the specific commands on the LCD user interface.

Attention: you should avoid stopping the unit using the main switch:

The latter device

should be used to disconnect the unit from the electricity supply when there is no

passage of current, i.e. when the unit is already turned OFF.

Moreover, if you completely disconnect the unit from the electricity supply, the crankcase

heating elements will receive no power, thereby jeopardising the integrity of the

compressor the next time the unit is started.

8 OPERATING

LIMITS

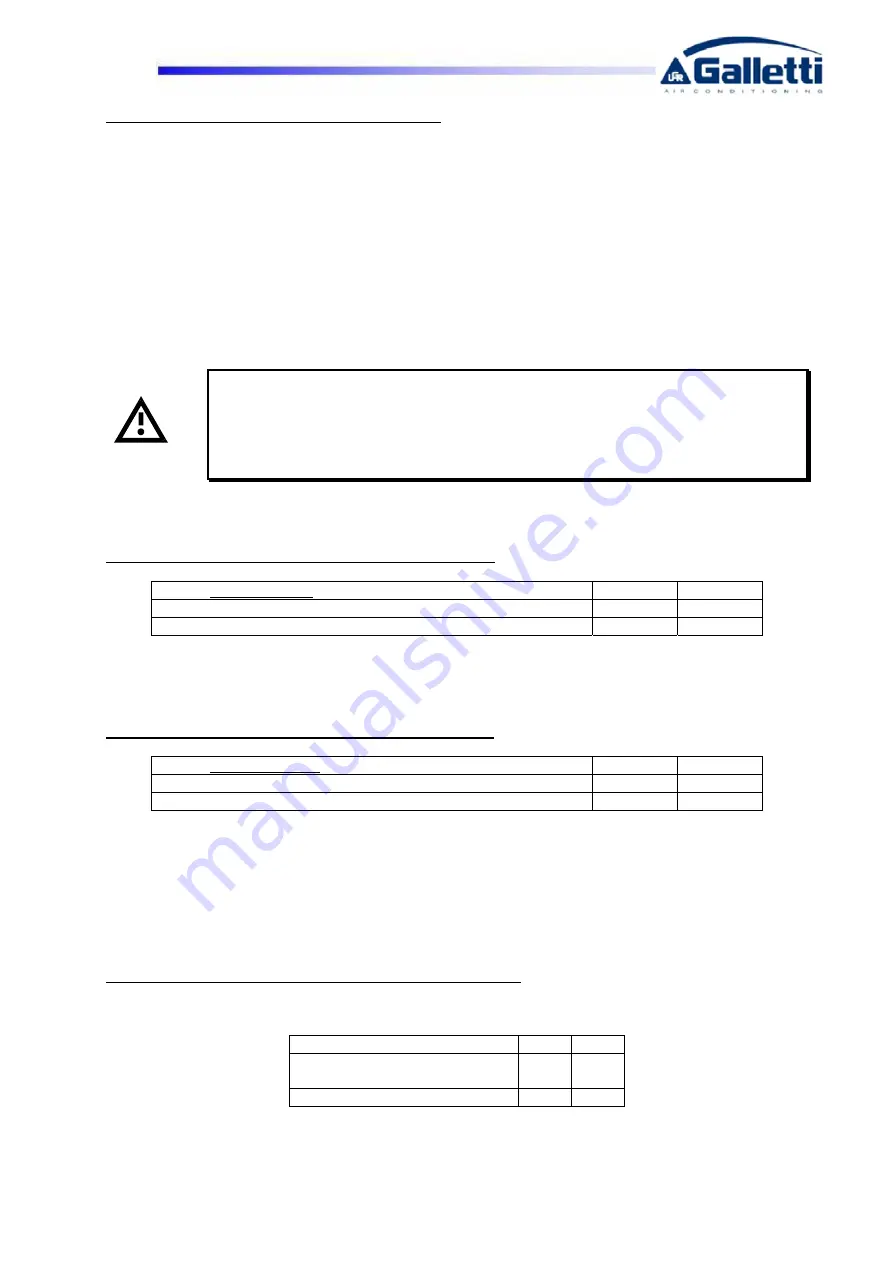

Operating limits of LCX chillers on COLD-ONLY mode:

Cold-only units: Min.

Max.

Evaporator outlet water temperature [°C]:

5

15

External air temperature [°C]:

-10

49

To operate with outdoor temperatures below 20 °C it is essential to employ the (optional) device

to monitor condensation: Monitoring via fan speed modulation with a cutting phase regulator for -

15°C < T outside air < +20 °C.

Operating limits of LCX chillers on HEAT PUMP mode:

Heat Pump Unit: Min.

Max.

Condenser outlet water temperature [°C]:

25

55

External air temperature [°C]:

-10

30

To operate with outdoor air temperatures below 0°C the temperature of the water produced will

be reduced to 45°C. It is essential to use the (optional) device to monitor evaporation to detect

the outlet water temp. from the condenser with an ambient temperature of the air greater than

20°C. For temp. of produced water between 25°C and 30°C is it compulsory to use an electrical

expansion valve.

The unit will automatically block itself below -10°C,

thanks to the external

low-temperature probe in order to protect the chilling compressors from non application fields

they were not designed for.

Operating limits of LCX chillers on FREE-COOLING mode:

LCX F in relation to the outlet water temperature and outdoor air temperature:

Min.

Max.

Evaporator outlet water

temperature [°C]:

5 13

External air temperature [°C]:

-18

44